TAC base for cycloolefin polymer bonding, TAC bonding member, and liquid crystal display device

A cycloolefin-based technology for bonding parts, applied in the direction of adhesives, adhesive additives, film/sheet-like adhesives, etc. Excellent strength, outgassing, and improved transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] (adhesive layer)

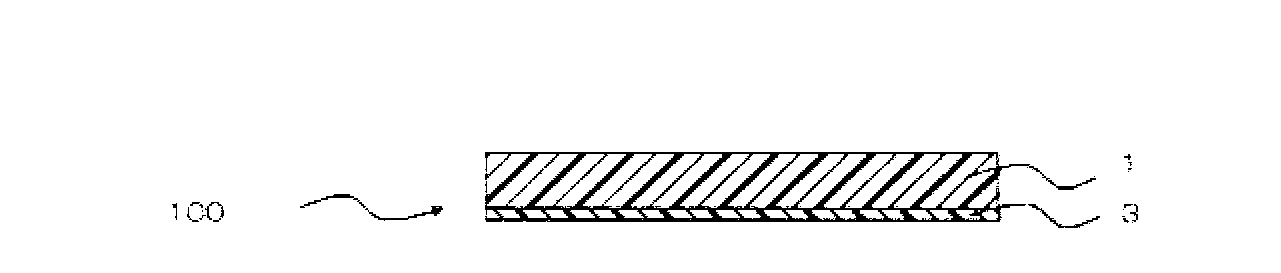

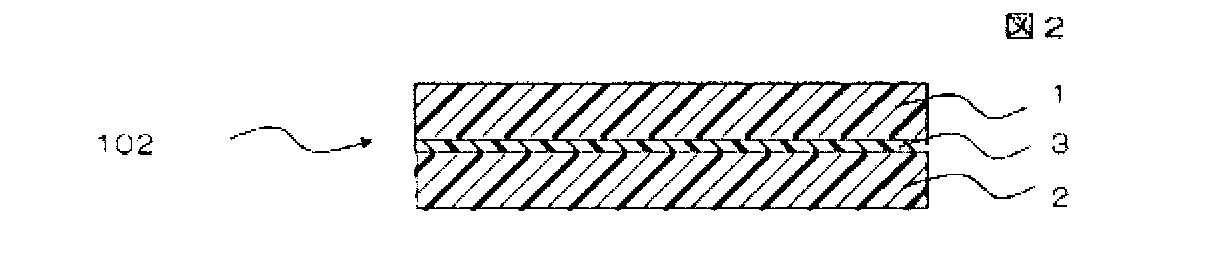

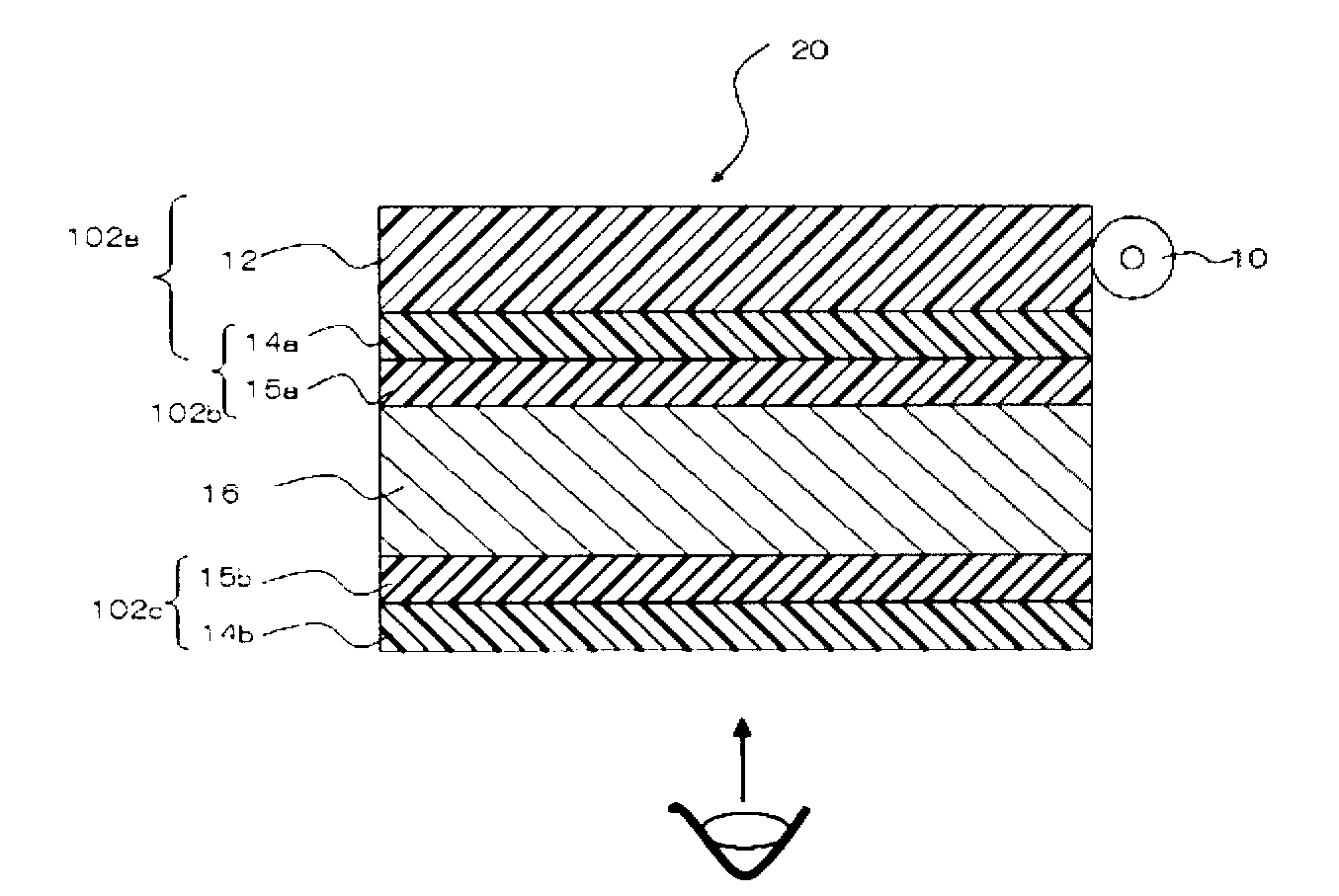

[0116] In the examples, an adhesive sheet made of a polymer (styrene-based thermoplastic elastomer), paraffin, and toluene was used. Adjustments were made so that the mixing ratio of the polymer, paraffin, and toluene was 10% by weight, 20% by weight, and 70% by weight. The adjusted sample was thoroughly stirred, and the above-mentioned adjusted coating solution was coated on a TAC film (FUJITAC: 80 μm) with a laboratory automatic coater so that the film thickness after drying was 30 μm. Dry at room temperature for 1 minute to form an adhesive layer, and leave to stand for 100 seconds in a hot air dryer set at 80° C. to remove the solvent toluene. Then, the TAC film was taken out from the drier, and a spacer (silica gel PET (Silicompet) 100 μm) was laminated to prepare a sample.

[0117] (Exhaust performance evaluation)

[0118] A rectangular test piece with a width of 10 mm and a length of 250 mm was cut out from the TAC adhesive sheet to be evalu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com