Detectors for movement speeds of semi-automatic consumable electrode and non-consumable electrode electric-arc welding molten baths

A technology of moving speed and detection device, applied in arc welding equipment, welding equipment, manufacturing tools, etc., to achieve the effect of high speed, high precision and long working distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

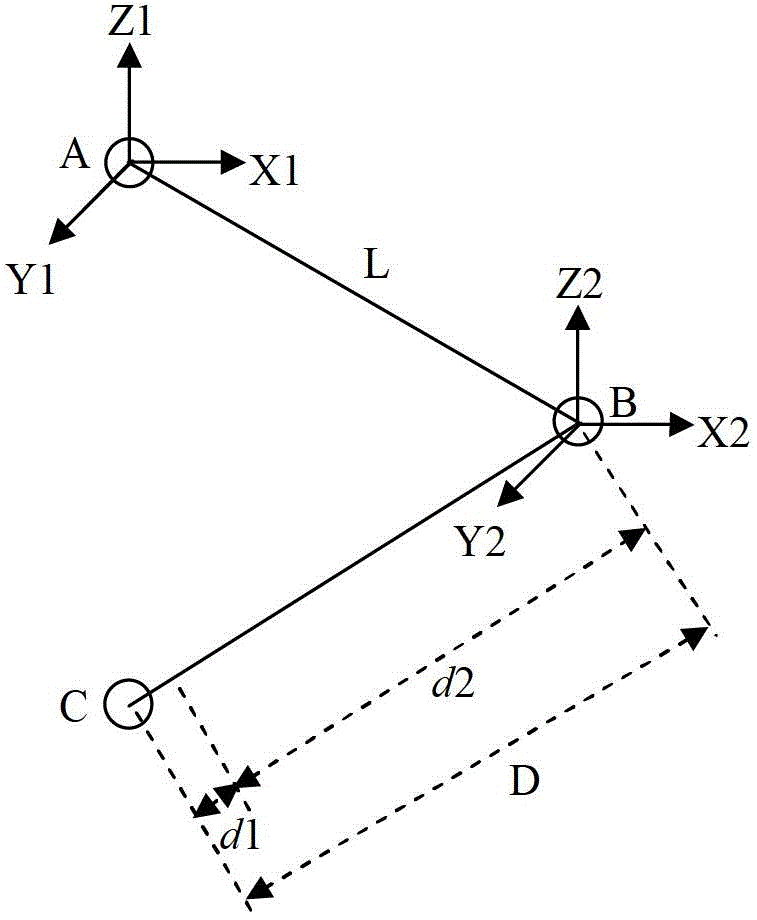

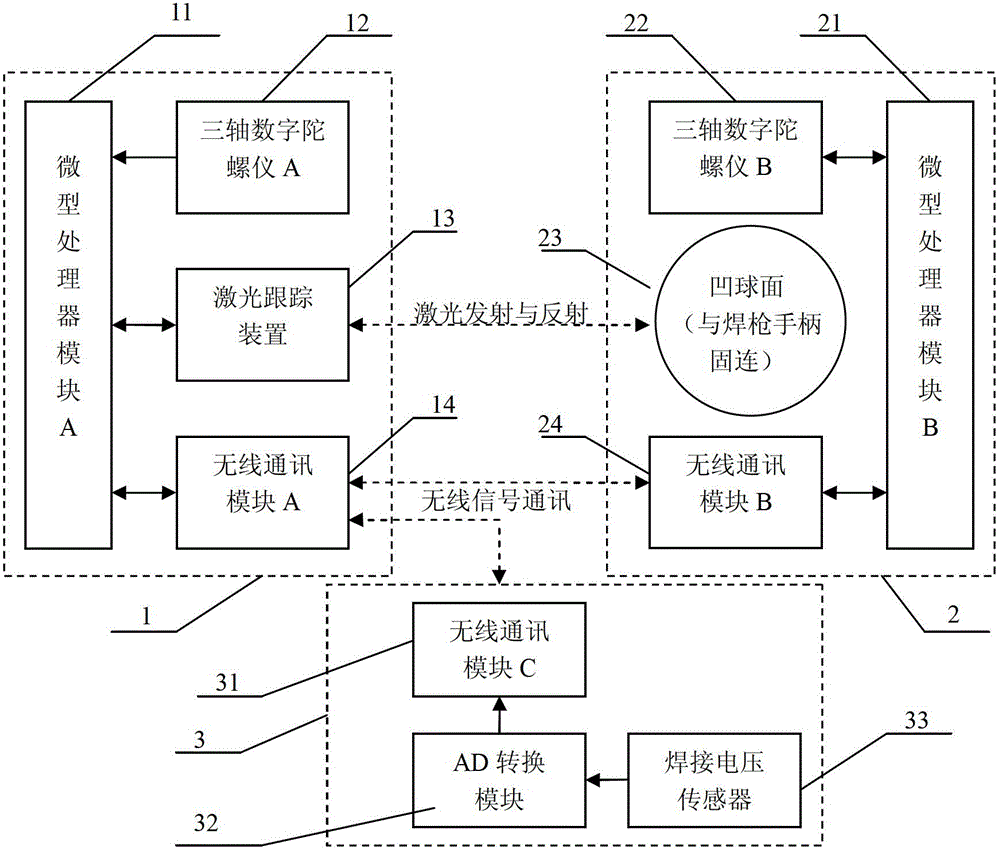

[0063] Such as figure 1 and figure 2 As shown, in the real-time detection device of the semi-automatic metal arc welding molten pool moving speed of the present invention, the molten pool moving speed calculator 1 is placed on a reference point A, and the azimuth sensor 2 of the molten pool center point C relative to the middle point B is installed On the welding gun handle, the welding voltage sensing module 3 is installed on the center point C of the molten pool; the molten pool moving speed calculator 1 includes: a microprocessor module A 11, a three-axis digital gyroscope A 12, a laser tracking device 13, a wireless Communication module A14; azimuth sensor 2 includes: microprocessor module B21, three-axis digital gyroscope B 22, concave spherical surface 23, wireless communication module B 24; welding voltage sensing module 3 includes: wireless communication module C31, AD conversion module 32. Welding voltage sensor 33.

[0064] Microprocessor module A11 has the follow...

Embodiment 2

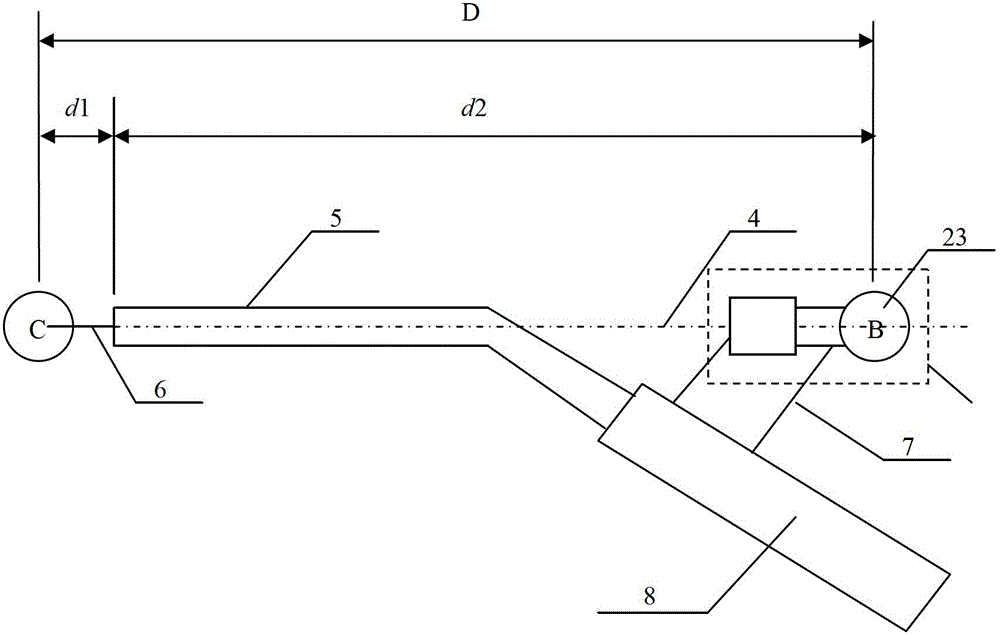

[0081] Such as figure 1 and Figure 4 As shown, in the real-time detection device of the semi-automatic non-melting electrode arc welding molten pool moving speed of the present invention, the molten pool moving speed calculator 1 is placed on a reference point A, and the azimuth sensor 2 of the molten pool center point C relative to the middle point B Installed on the handle of the welding gun; the molten pool moving speed calculator 1 includes: a microprocessor module A 11, a three-axis digital gyroscope A 12, a laser tracking device 13, and a wireless communication module A14; the azimuth sensor 2 includes: a microprocessor module B 21, three-axis digital gyroscope B 22, concave spherical surface 23, wireless communication module B 24.

[0082] Microprocessor module A11 has the following four functions:

[0083] ① Control the laser tracking device 13 to emit laser light to the concave spherical surface 23, calculate the length L of the straight line AB, and adjust the las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com