Numerical control stone multi-plate continuous cutting assembly line

An assembly line and stone technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of high labor intensity, unsanitary and unsafe working environment, etc., to ensure the health and safety of the working environment, and prevent dust and water mist. The effect of spillover and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

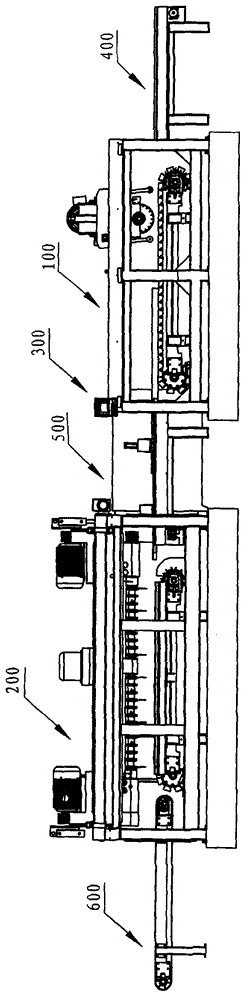

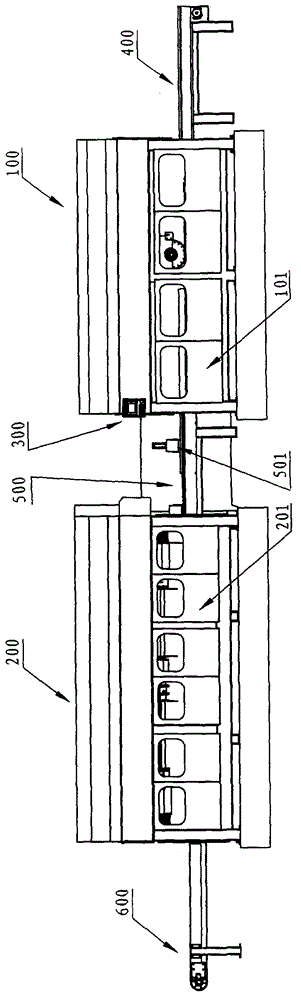

[0047] Such as figure 1 , figure 2 As shown, the overall structure of the present invention is composed of six major parts, including the numerical control system 300, and the feeding workbench 400, No. I longitudinal cutting machine 100, transition workbench 500, and No. II The horizontal cutting machine 200 and the blanking workbench 600 ; the working cooperation and connection between the above five components are automatically controlled by the numerical control system 300 . in:

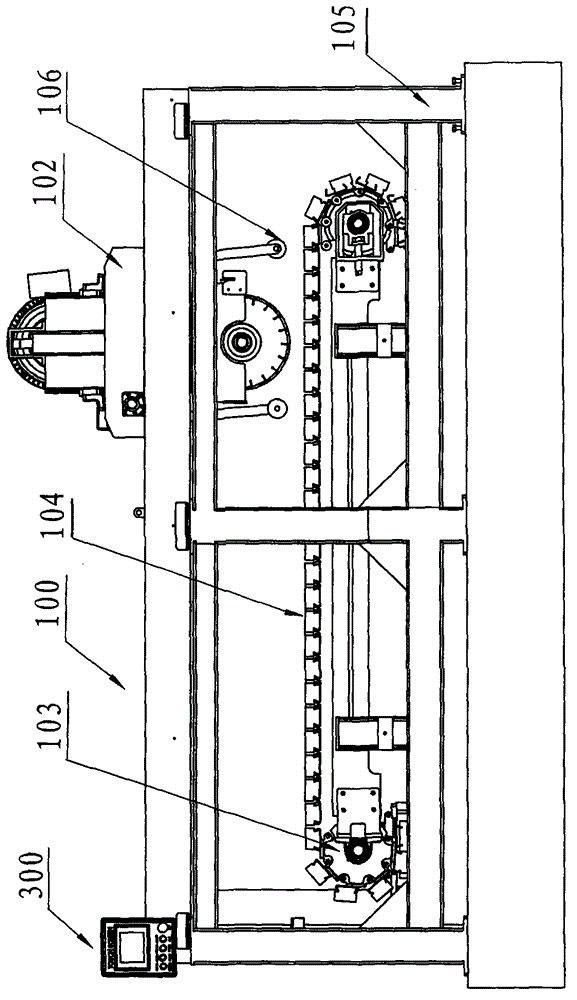

[0048] (1) No. I longitudinal cutting machine: refer to Figure 1-Figure 4 .

[0049] No. 1 longitudinal cutting machine 100 mainly realizes the longitudinal trimming of slate.

[0050] Depend on figure 2 It can be seen that No. I longitudinal cutting machine 100 is referred to as No. I machine for short, and it is installed on No. I frame 105 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com