Device and method for electrolytic treatment of acid organic wastewater with high salinity

A technology for electrolytic treatment and organic wastewater, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of inapplicability, poor targeting of single electrolytic reaction, low reaction efficiency, etc. , to achieve the effect of improving electrolysis efficiency, realizing multi-functionalization, and reducing chloride ion concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

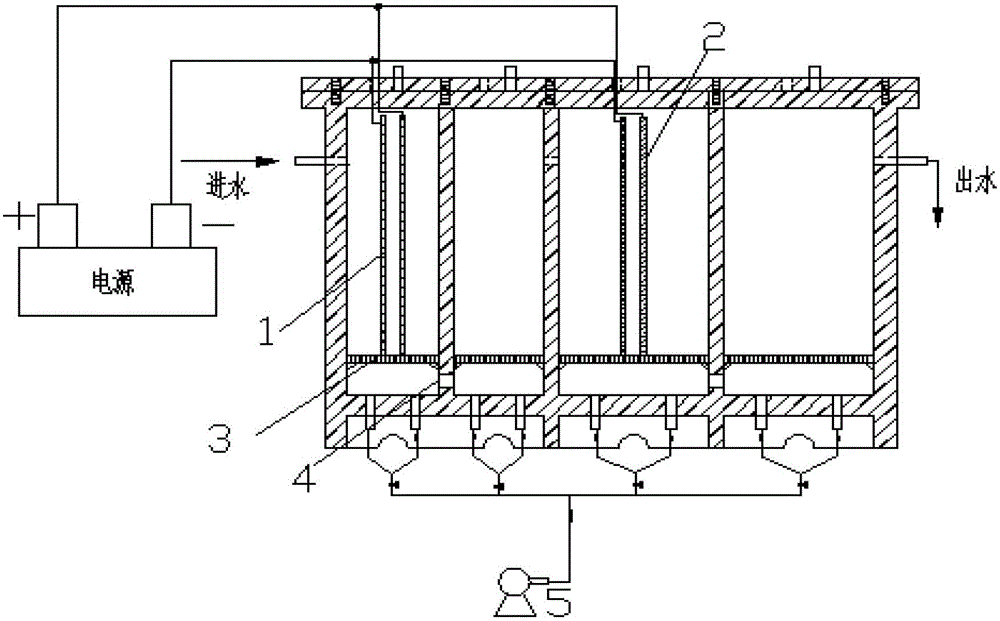

[0033] Such as figure 1 As shown, an electrolytic treatment device for organic wastewater includes a reactor and a power supply. The reactor is provided with a plurality of connected reaction chambers. The water inlet and the water outlet are respectively connected to the two outermost reaction chambers. There is a diversion hole for the flow of waste water between the two reaction chambers, and the reaction chamber is covered with a top cover; the current is kept at a constant current of 10A through the regulation of the power supply.

[0034] The reaction chamber includes at least two electrolysis chambers. Different types of electrode pairs are arranged in the electrolysis chambers, and the electrode pairs are connected to the power supply through connecting wires. At least one reaction ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com