High temperature resistance odorless peroxide rubber composition and preparation method thereof

A kind of rubber composition, peroxide technology, applied in the field of rubber composition, can solve the problem of odor, increase cost and the like that are not completely solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

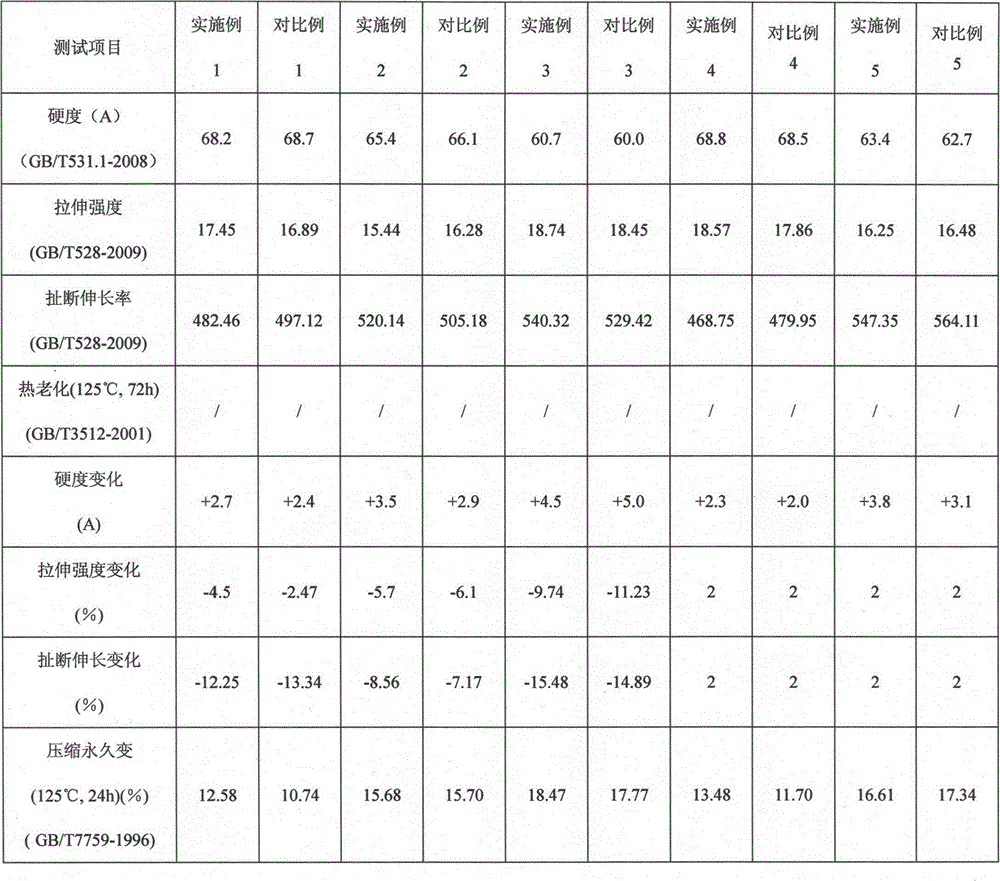

Examples

Embodiment 1

[0024] A kind of odorless peroxide rubber composition contains following components in parts by weight:

[0025] EPDM rubber: 100; paraffin oil: 5;

[0026] Zinc oxide: 5; Vulcanizing agent DCP: 5;

[0027] Stearic acid: 1; Cross-linking agent TAIC: 1.8;

[0028] Antiaging agent RD: 2; Sulfur: 0.3;

[0029] Antiaging agent 4010NA: 2; Methyl ionone: 0.5.

[0030] Carbon black N-550: 50;

[0031] The effects obtained in this embodiment are: simple formula, low price, excellent heat resistance, easy operation, no pungent odor during the vulcanization process, and the obtained product has a slight fragrance.

Embodiment 2

[0033] A kind of odorless peroxide rubber composition contains following components in parts by weight:

[0034] Nitrile rubber: 100; Dioctyl fat: 5;

[0035] Zinc oxide: 5; Vulcanizing agent DCP: 3;

[0036] Stearic acid: 1; Cross-linking agent TAIC: 1.8;

[0037] Antiaging agent RD: 2; Sulfur: 0.3;

[0038] Antiaging agent 4010NA: 2; methyl ionone: 0.3.

[0039] Carbon black N-550: 50;

[0040] The effects obtained in this embodiment are: simple formula, low price, excellent heat resistance, easy operation, no pungent odor during the vulcanization process, and the obtained product has a slight fragrance.

Embodiment 3

[0042] A kind of odorless peroxide rubber composition contains following components in parts by weight:

[0043] Natural rubber: 100; naphthenic oil: 5;

[0044] Zinc oxide: 5; Vulcanizing agent DCP: 2;

[0045] Stearic acid: 1; Cross-linking agent TAIC: 1.8

[0046] Antiaging agent RD: 2; Sulfur: 0.5;

[0047] Antiaging agent 4010NA: 2; methyl ionone: 0.1.

[0048] Carbon black N-550: 50;

[0049] The effects obtained in this embodiment are: simple formula, low price, excellent heat resistance, easy operation, no pungent odor during the vulcanization process, and the obtained product has a slight fragrance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com