Automatic furnace door mechanism for PECVD device

A furnace door, automatic technology, used in gaseous chemical plating, metal material coating process, coating and other directions, can solve problems such as sealing failure, improve production efficiency, and ensure good equipment vacuum effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

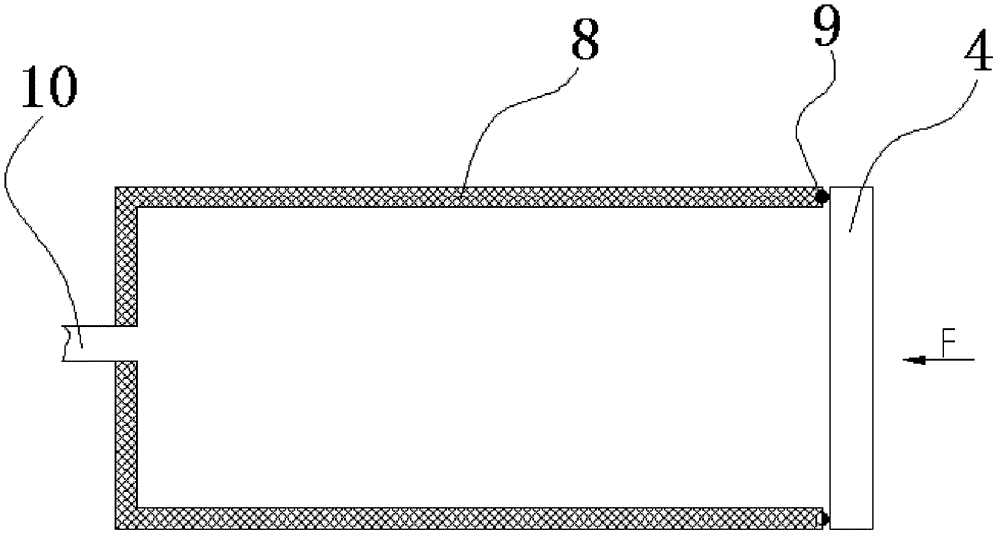

[0019] figure 1 It is a schematic diagram of the sealing method of the furnace door mechanism. The tubular PECVD equipment uses a quartz tube 8 as a deposition chamber, and an O-ring 9 is used to seal between the furnace door flange 4 and the quartz tube. Vacuum produces atmospheric pressure F to compress the furnace door flange 4 to achieve sealing.

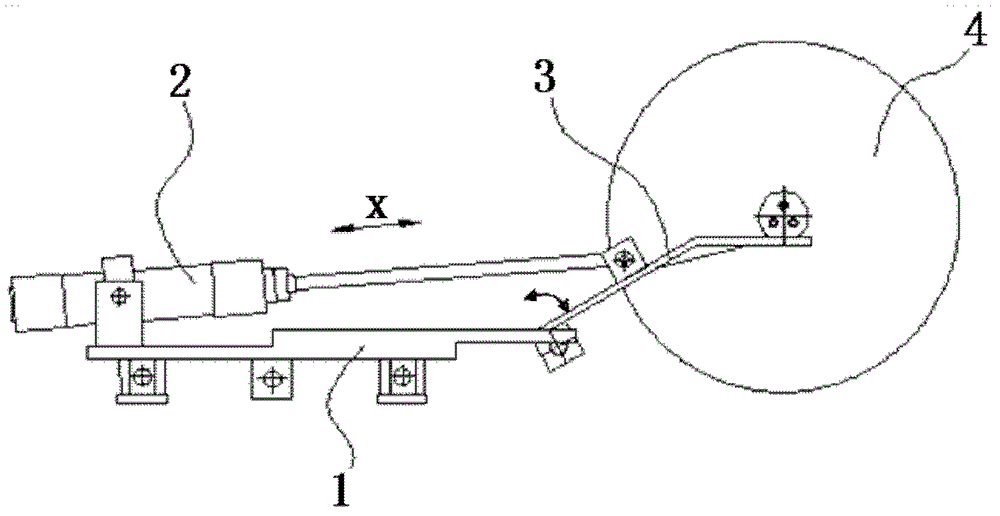

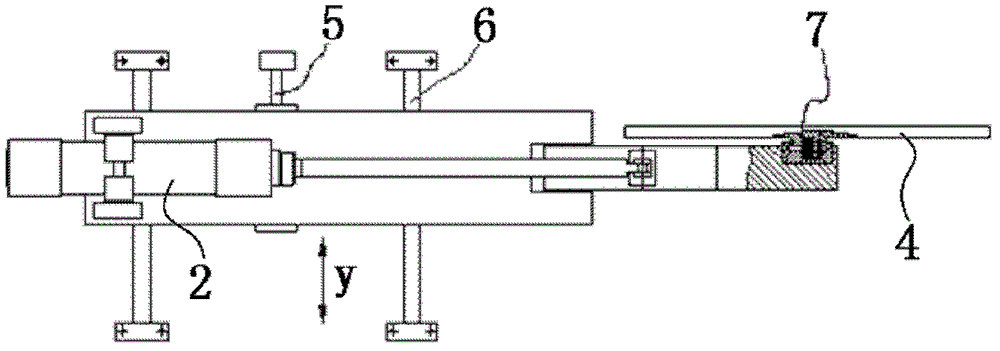

[0020] figure 2 and image 3 Schematic diagram of the working principle of the furnace door mechanism. figure 2 It includes an x-direction cylinder 2 and a y-direction cylinder 5, a base 1, a connecting rod 3, and a furnace door flange 4. Two double-acting cylinders 2 and 5 realize movement in two directions, and one x-direction cylinder 2 realizes the rotation of the furnace door flange 4 by pushing and pulling the connecting rod 3 , ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com