Special alloy wax-proofing tool

A technology for preventing wax and alloys, which is used in cleaning appliances, drilling compositions, drilling equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

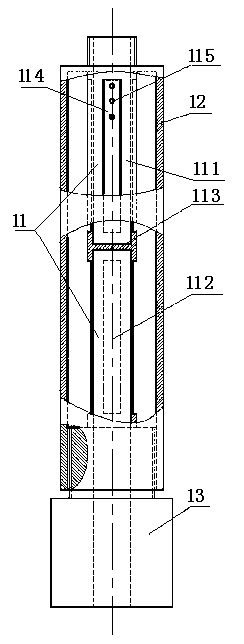

[0041] A pipeline-type special alloy wax-proof tool (see figure 1 ), consisting of an alloy tube 11, an outer sleeve 12 and a convex combiner 13; the outer sleeve 12 is set on the outside of the alloy tube 11, and then fixedly connected with a convex combiner 13; the alloy tube 11 is made of wax-resistant alloy A , divided into upper section 111 and lower section 112, with a plug 113 in the middle, and the outer walls of the upper section 111 and lower section 112 of the alloy tube have multiple connected grooves 114, and a large number of small holes 115 are opened at the bottom of the groove 114.

[0042]

Embodiment 2

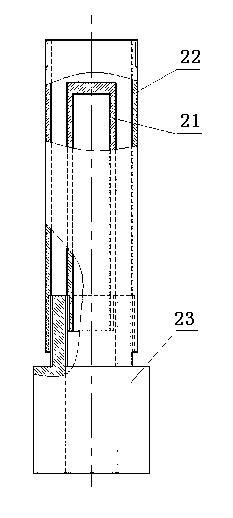

[0044] A coating type special alloy wax-proof tool (see figure 2 ), consisting of an inner tube 21, an outer tube 22 and a convex combiner 23; the outer tube 22 is set outside the inner tube 21, and then fixedly connected with the convex combiner 23; the inner tube 21 is a metal material matrix, and the tube wall There are a large number of small holes, and the inner wall and outer wall of the inner pipe 21 and the inner wall of the outer pipe 22 are sprayed with a wax-proof metal B surface layer.

[0045]

Embodiment 3

[0047] A combined special alloy anti-wax tool, in which the pipeline-type special alloy anti-wax tool (the specific structure is the same as in Example 1) and the coating-type special alloy anti-wax tool (the specific structure is the same as in Example 2) are respectively passed through the joint It is connected in series in the oil well pipeline, located 10 meters and 20 meters below the oil well pump. Among them, the specific composition of the anti-wax alloy A in the pipeline-type special alloy anti-wax tool is (by weight percentage): Ni 23.3, Cu 54.7, Zn 15.1, Sn 1.3, Pb 3.1, Co 1.4, Gd 0.5, Ti 0.5, B 0.10; the metal material substrate in the coated special alloy wax-proof tool is a stainless steel substrate, and the wax-proof alloy formed on the substrate by flame spraying method B surface layer, the thickness of the surface layer is 30 microns, the specific composition of alloy B is (by weight percentage): Cu 88.0, Ni 10.5, Co 1.0, Gd 0.5;

[0048] The depth of the oil ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com