Preparation method of porous graphene-based air purification agent

An air purifier and porous graphene technology, applied in chemical instruments and methods, separation methods, physical/chemical process catalysts, etc., can solve problems such as human hazards and secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

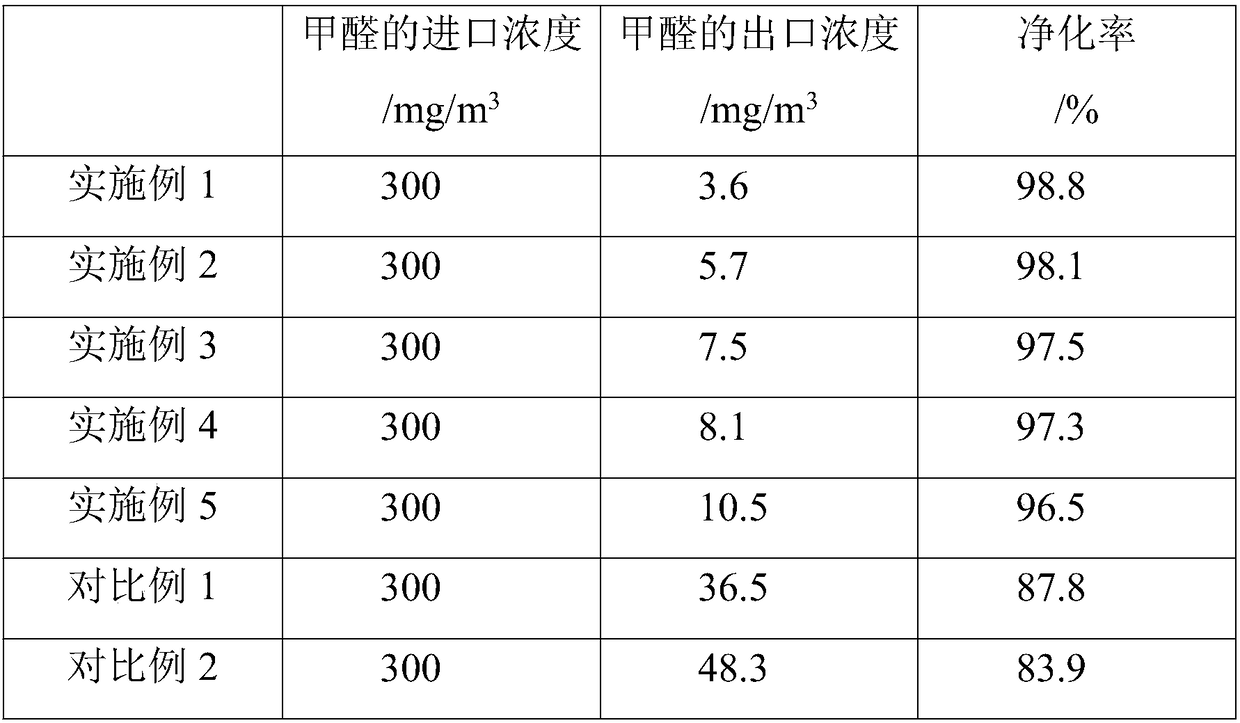

Examples

preparation example Construction

[0013] The present invention also provides a kind of preparation method of described porous graphene-based air cleaner, comprises the following steps:

[0014] (1) Add foaming agent to polypropylene resin and mix evenly, then obtain polypropylene fiber by electrospinning, and calcinate polypropylene fiber at 300-450°C for 2-4 hours to obtain porous carbon fiber;

[0015] (2) Mix porous carbon fiber, soluble metal salt, silane coupling agent and organic titanate in a solvent to obtain a mixed system, then add inorganic acid to adjust the pH value of the mixed system to be acidic, and then sonicate for 15 to 30 minutes, Then seal and react at 80-120°C for 3-6 hours to obtain modified porous carbon fibers;

[0016] (3) Mix graphene oxide and oxometalate in an aqueous solution evenly, then add melamine, and then seal and react at 80-150°C for 3-8 hours under airtight conditions to obtain a mixed system, and then put the mixed system in the microwave The reaction was carried out f...

Embodiment 1

[0026] A porous graphene-based air cleaner, made of the following parts by weight: 8 parts by weight of tetraethyl titanate, 0.5 parts by weight of nickel acetate, 1.5 parts by weight of silane coupling agent KH7921, 4 parts by weight of graphene oxide , 4 parts by weight of sodium tungstate, 4 parts by weight of melamine, 3 parts by weight of N,N'-dinitrosopentamethylenetetramine, 105 parts by weight of polypropylene resin, 4 parts by weight of hydrochloric acid (2M), 50 parts by weight of ethanol share.

[0027] The preparation method of described porous graphene-based air cleaner comprises the following steps:

[0028] (1) Add N,N'-dinitrosopentamethylenetetramine to polypropylene resin and mix evenly, then obtain polypropylene fiber by electrospinning. The electrospinning process is: power supply voltage 50kV, spinning The temperature is 35°C, the relative humidity is 75%; the needle spacing of the multi-needle spinneret unit is 35cm, and the number of needleheads of the ...

Embodiment 2

[0034] A porous graphene-based air cleaner, made of the following parts by weight: 5 parts by weight of tetraisopropyl titanate, 0.8 parts by weight of magnesium nitrate, 1.8 parts by weight of silane coupling agent KH580, 6 parts by weight of graphene oxide 3 parts by weight of sodium molybdate, 5 parts by weight of melamine, 2 parts by weight of N,N'-dinitrosopentamethylenetetramine, 100 parts by weight of polypropylene resin, 3 parts by weight of hydrochloric acid (3M), 45 parts by weight of water parts by weight.

[0035] (1) Add N,N'-dinitrosopentamethylenetetramine to polypropylene resin and mix evenly, then obtain polypropylene fiber by electrospinning. The electrospinning process is: power supply voltage 50kV, spinning The temperature is 35°C, the relative humidity is 75%; the needle spacing of the multi-needle spinneret unit is 35cm, and the number of needleheads of the spinneret unit is 90;

[0036] Calcining polypropylene fibers at 400°C for 2.5 hours to obtain por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com