Preparation method of fuel cell platinum-based alloy catalyst

A platinum-based alloy and fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor stability of precursor solution, unfavorable rapid production, long heating time, etc., to facilitate rapid production and improve catalytic performance , the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

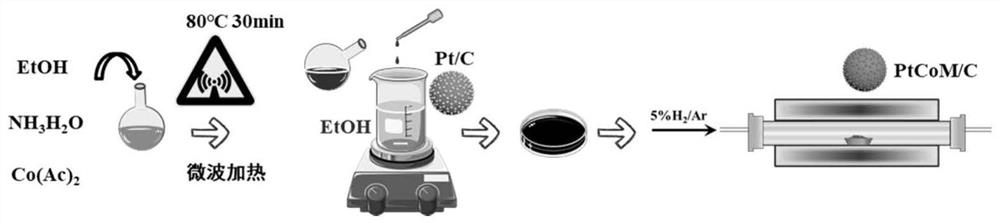

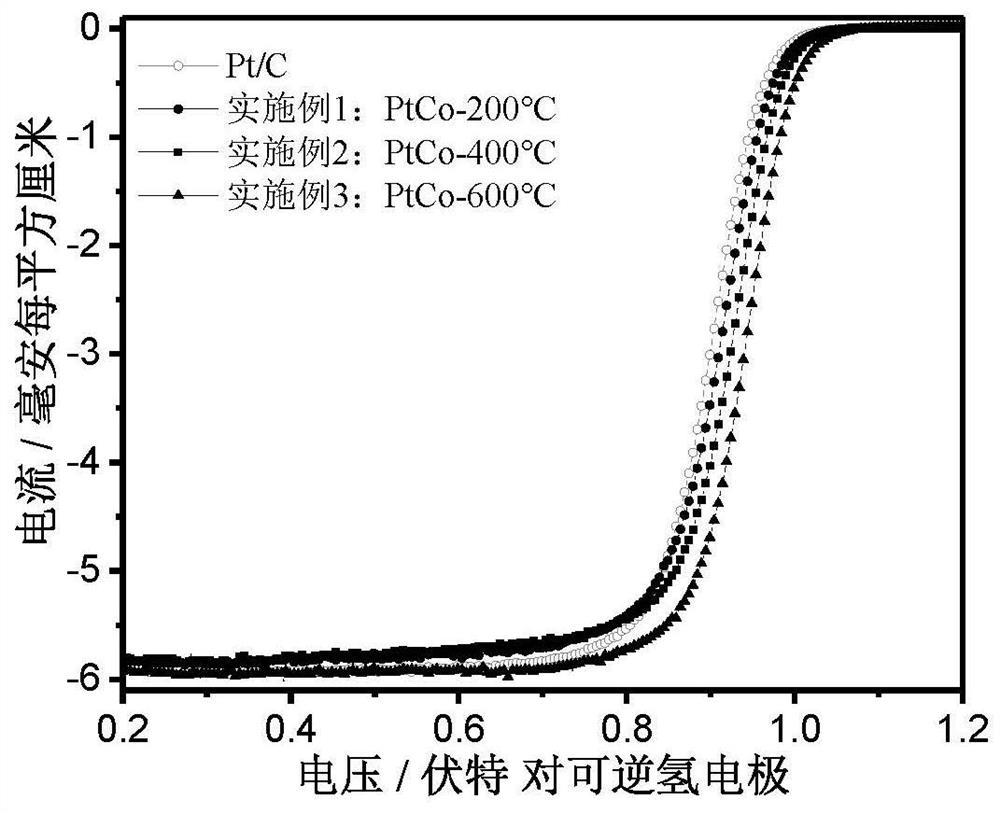

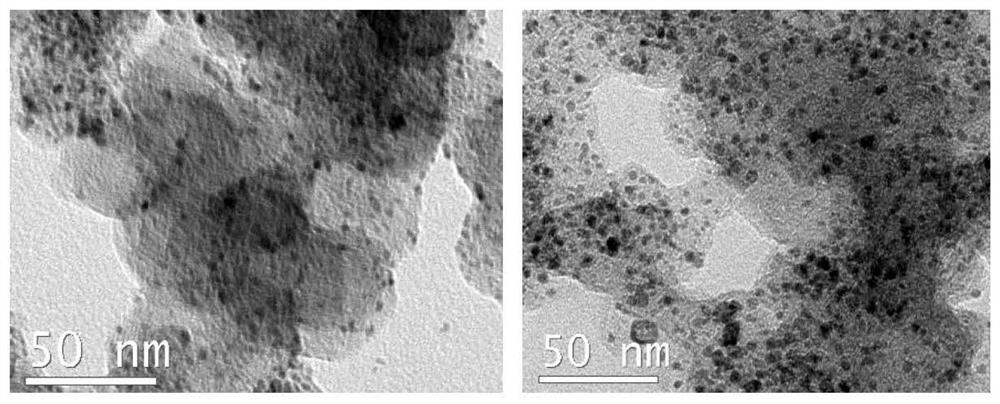

Embodiment 1

[0032] Add 0.4g of cobalt acetate tetrahydrate to 50mL of ethanol, stir until dissolved, add 3mL of concentrated ammonia solution with a mass fraction of 28%, and stir in the air until the color of the solution turns dark brown, then transfer the solution to a microwave oven. In the reactor, heat with a heating power of 500W for 30min, mix the obtained precursor with 200mg of commercial platinum carbon with a platinum mass loading of 20%, and anneal at 200°C for 4h after heating and drying, and the annealing atmosphere is H 2 / Ar, the hydrogen mass fraction is 5%.

Embodiment 2

[0034] Add 0.4g of cobalt acetate tetrahydrate to 50mL of ethanol, stir until dissolved, add 3mL of concentrated ammonia solution with a mass fraction of 28%, and stir in the air until the color of the solution turns dark brown, then transfer the solution to a microwave oven. In the reactor, heat with a heating power of 500W for 30min, mix the obtained precursor with 200mg of commercial platinum carbon with a platinum mass loading of 20%, and anneal at 400°C for 4h after heating and drying, and the annealing atmosphere is H 2 / Ar, the hydrogen mass fraction is 5%.

Embodiment 3

[0036] Add 0.4g of cobalt acetate tetrahydrate to 50mL of ethanol, stir until dissolved, add 3mL of concentrated ammonia solution with a mass fraction of 28%, and stir in the air until the color of the solution turns dark brown, then transfer the solution to a microwave oven. In the reactor, heat with a heating power of 500W for 30min, mix the obtained precursor with 200mg of commercial platinum carbon with a platinum mass loading of 20%, and anneal at 600°C for 4h after heating and drying, and the annealing atmosphere is H 2 / Ar, the hydrogen mass fraction is 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com