Shield construction method for continuously under-passing dense buildings in silty-soil and silty-sand formation

A construction method and building technology, applied in building construction, earthwork drilling, underground chambers, etc., can solve problems such as large cumulative settlement, and achieve the effects of reducing surface settlement, reducing construction costs, and reducing disturbances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

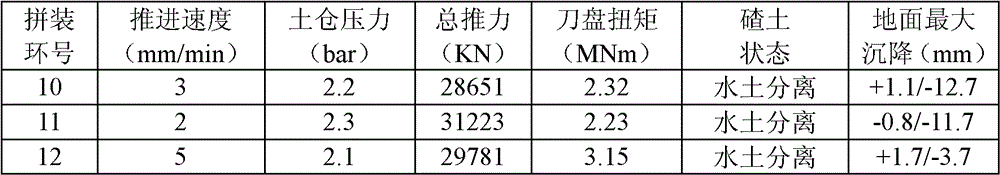

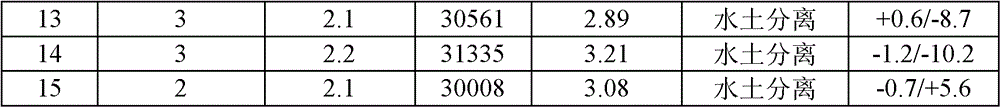

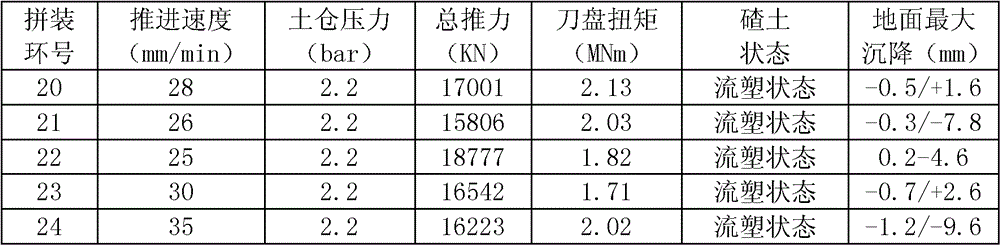

[0030] Taking shield tunneling in a silt and silt stratum as an example, the total length of the double lines of the project is 2238.442m, with a total of 1866 rings, of which the left line is 1116.447m long (931 rings), and the right line is 1121.995m long (935 rings). The total length of the double line is 2238.442m, with a total of 1866 rings, of which the left line is 1116.447m long (931 rings), and the right line is 1121.995m long (935 rings). The minimum radius of the interval plane is 450m, the minimum vertical slope is 2‰, and the maximum slope is 25.567‰. The minimum buried depth of the tunnel center is 12.635m, and the maximum buried depth is 20.35m. Advance to the 21st ring on the left line, and the 22nd ring on the right line, and the tunnel begins to pass through dense houses continuously, advance to the 695th ring on the left line, and complete the crossing of the residential area by the 701 ring on the right line, and start to pass through the original water pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com