Method for manufacturing touch screen and touch screen

A manufacturing method and touch screen technology, applied in the field of mobile communication, can solve the problems of complex touch screen manufacturing process, and achieve the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

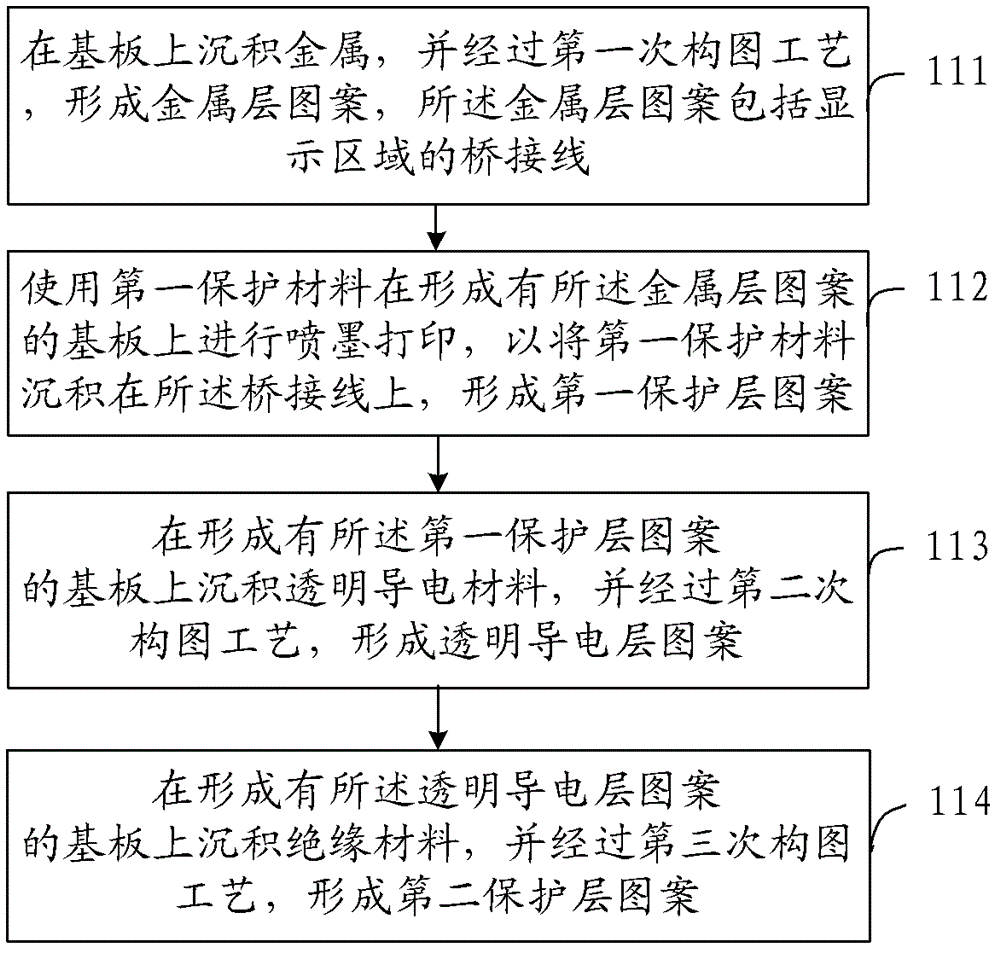

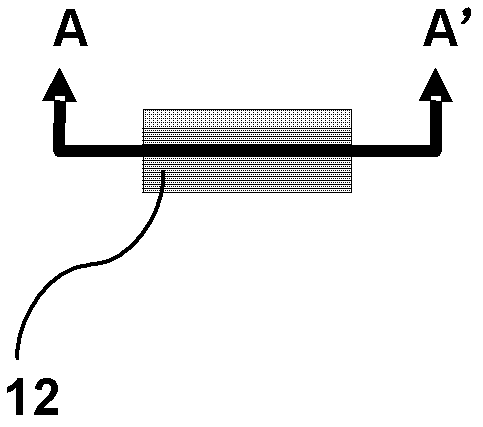

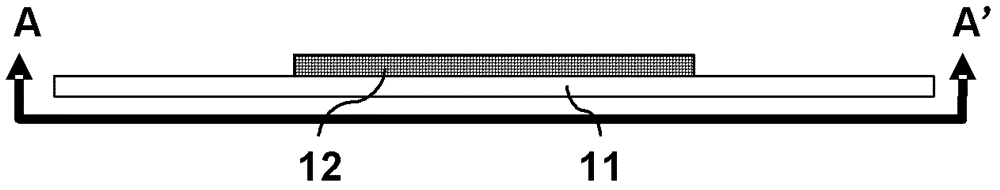

[0079] The manufacturing method of touch screen Touch Panel of the present invention, Figure 5A It is a top view of the display area of the touch screen finally generated by this scheme, Figure 5B It is a cross-sectional view of the touch screen finally generated by this solution, and only 3 Masks are needed. Such as figure 1 As shown, it is a schematic flow chart of an embodiment of the manufacturing method of the touch screen according to the present invention, including:

[0080] In step 111, metal is deposited on the substrate 11, and the metal layer pattern 12 is formed after the first photomask exposure, etching, and stripping, and the metal layer pattern includes bridge lines in the display area; wherein, the metal layer p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com