A high-temperature incineration and solidification method for radioactive waste resin plasma

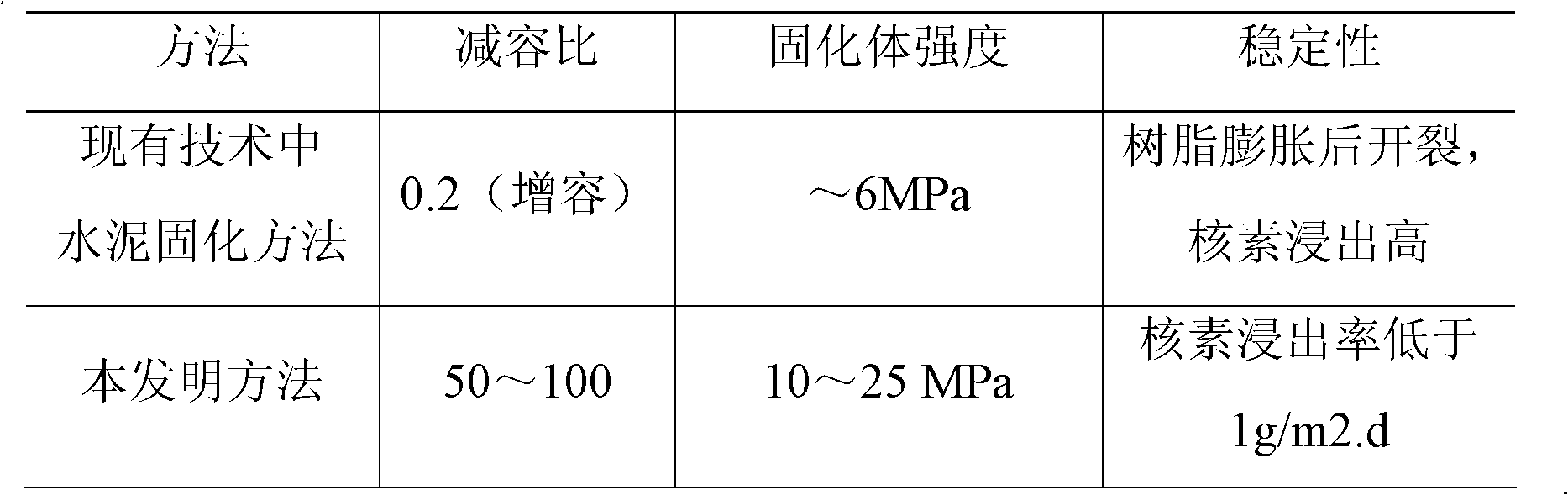

A radioactive waste resin and plasma technology, applied in radioactive purification, nuclear engineering, etc., can solve the problems that can not completely solve the problem of resin degradation combustible gas, reduce the volume of waste resin, unfavorable long-term disposal, etc., to achieve the final disposal and leaching rate The effect of low and stable product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

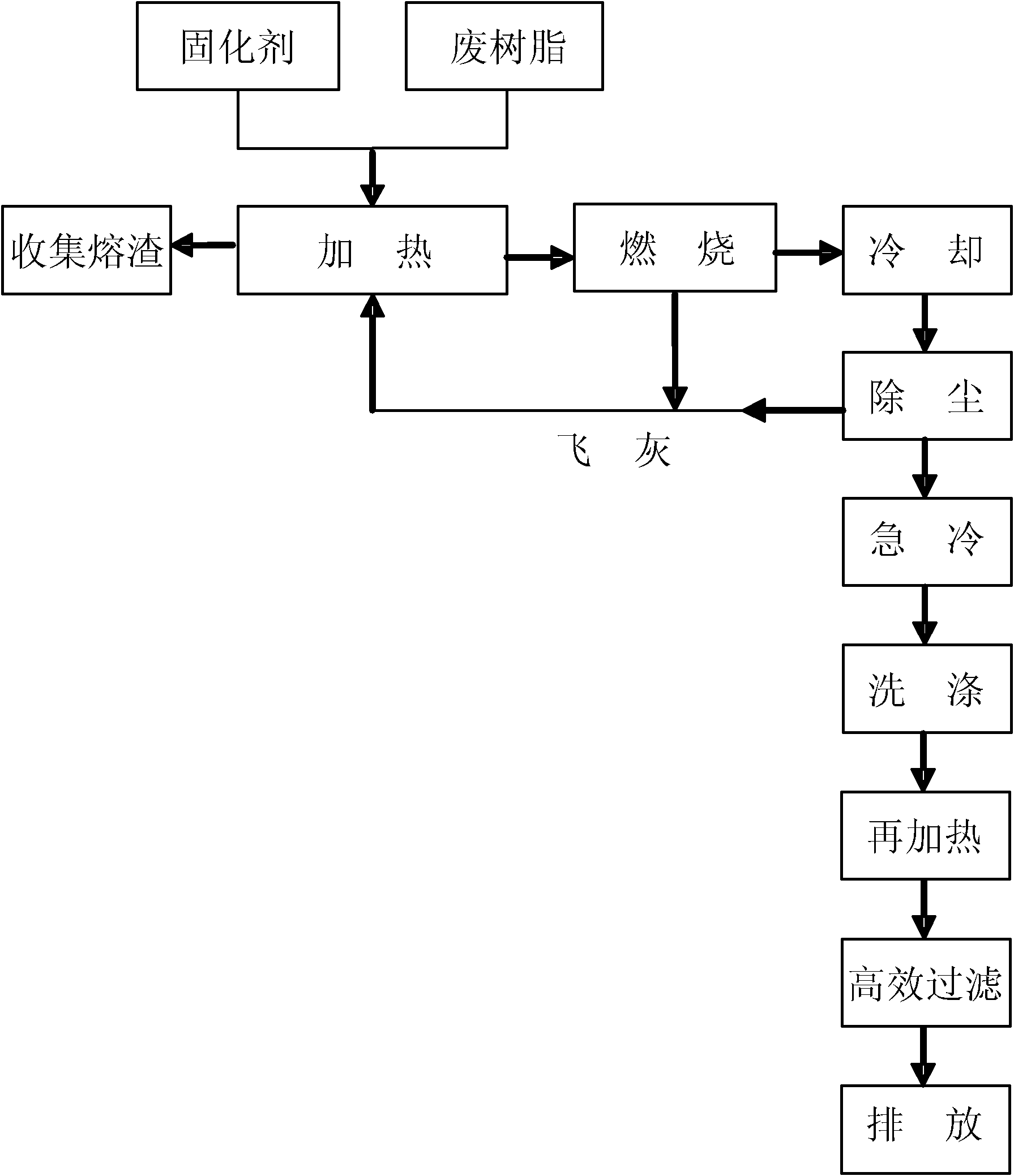

[0026] The radioactive waste resin plasma high-temperature incineration solidification method of the present invention comprises the following steps:

[0027] Step 1. Mix waste resin and curing agent according to the mass ratio of 7:1, and heat the mixture at 1300°C. The organic components in the waste resin are decomposed to generate flammable gas; the inorganic components and radionuclides in the waste resin, together with the curing agent, are melted at the above-mentioned high temperature, and the slag is collected, and a stable glass body is obtained after the slag is cooled. The curing agent may be borosilicate. The heating operation can be performed in a plasma melting furnace, and the slag collection can be completed through a slag collector, which is common knowledge to those skilled in the art.

[0028] Step 2. Mix the combustible gas described in step 1 with air, the volume ratio of the combustible gas and air is 2.5:1; the mixture of the above combustible gas and ...

Embodiment 2

[0039] Such as figure 1 As shown, the difference between this embodiment and embodiment 1 is that the fly ash generated by combustion in step 2 and the fly ash generated by dust removal in step 3 are returned to step 1 for slag collection to avoid secondary pollution.

Embodiment 3

[0041] This embodiment includes the following steps:

[0042] Step 1. Mix the waste resin and the curing agent according to the mass ratio of 10:1, and heat the above mixture at a temperature of 1340°C. The organic components in the waste resin are decomposed to generate flammable gas; the inorganic components and radionuclides in the waste resin, together with the curing agent, are melted at the above-mentioned high temperature, and the slag is collected, and a stable glass body is obtained after the slag is cooled.

[0043] Step 2. Mix the combustible gas described in step 1 with air, the volume ratio of the combustible gas and air is 2:1; the mixture of the above combustible gas and air is ignited in a combustion chamber with a temperature of 1150° C. The air is sent in and out to support the combustion, so as to ensure the full combustion of the flammable gas and produce smoke after combustion.

[0044] Step 3. Cool the flue gas generated in step 2 to 625°C, and then filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com