Loop heat pipe structure

A loop heat pipe and tube body technology, which is applied to circuits, indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as large space, difficulty in initial startup of flat-plate loop heat pipes, and thermal resistance of most parts of the evaporator. To achieve the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The above-mentioned objects and structural and functional characteristics of the present invention will be described based on the preferred embodiments of the accompanying drawings.

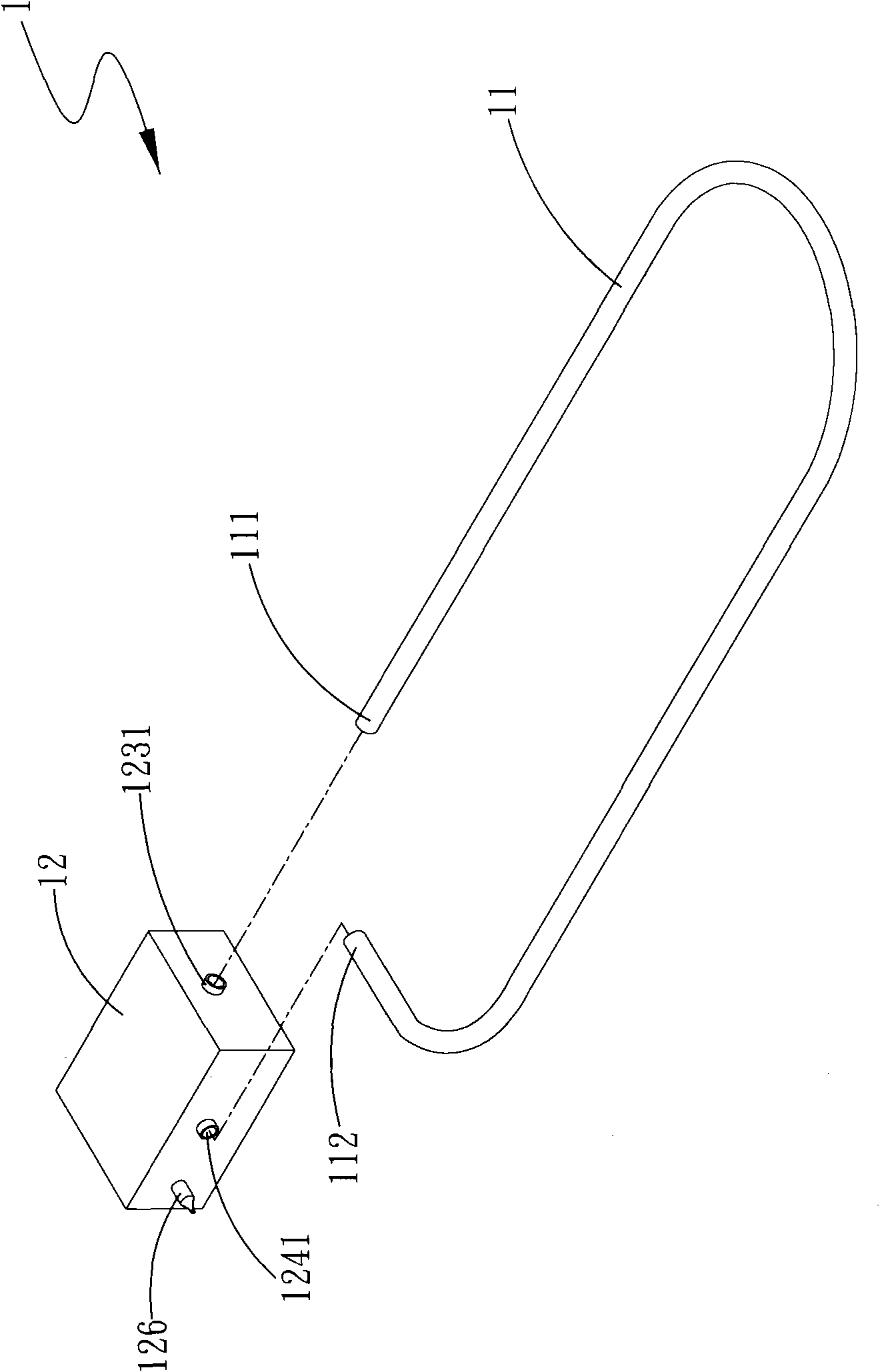

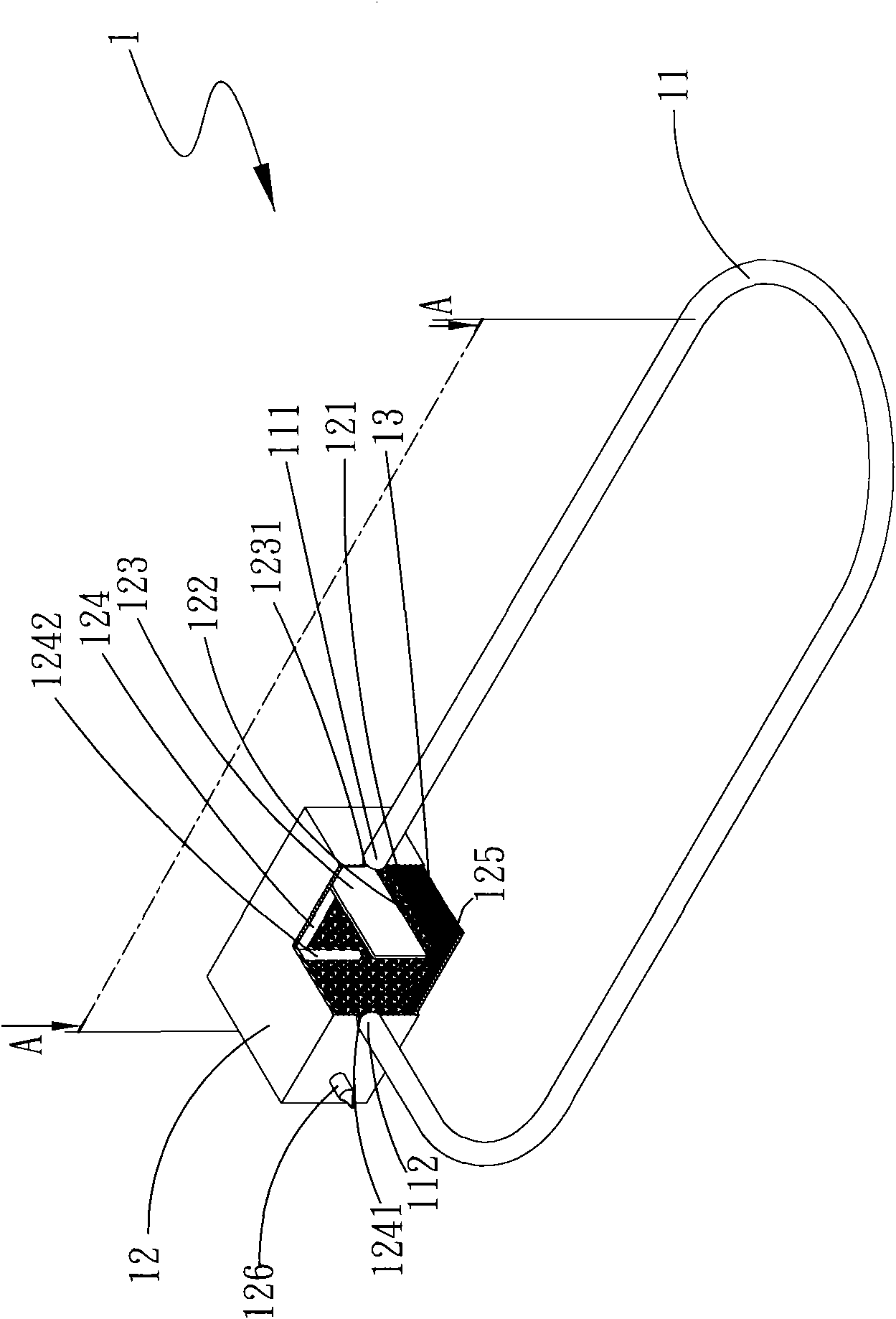

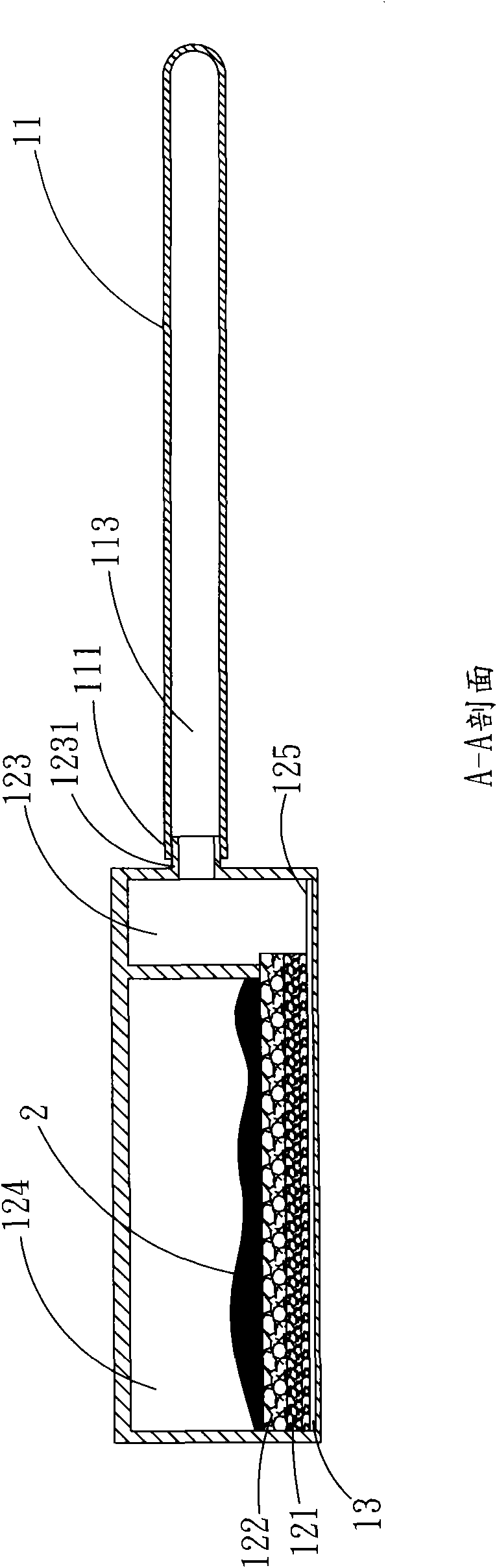

[0039] See figure 1 , figure 2 , image 3 , Is a three-dimensional exploded and combined cross-sectional view and AA cross-sectional view of the first embodiment of the loop heat pipe structure of the present invention. As shown in the figure, the loop heat pipe structure 1 of the present invention includes: a tube body 11, a cavity 12, and a first A capillary layer 121, a second capillary layer 122 and multiple grooves 13;

[0040] The tube body 11 has a first end 111 and a second end 112 and a passage 113 which communicates with the first and second ends 111 and 112.

[0041] The cavity 12 has a first cavity 123 and a second cavity 124, working fluid 2 and a bottom 125, the first cavity 123 has a first connection hole 1231, and the second cavity 124 There is a second connecting hole 1241, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com