Technique for processing protein feed by insects

A protein feed and production technology technology, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of not improving immunity, destroying nutrients, and being difficult to absorb, so as to enhance immunity and disease resistance, Easy to digest and absorb, and the effect of reducing the cost of medication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

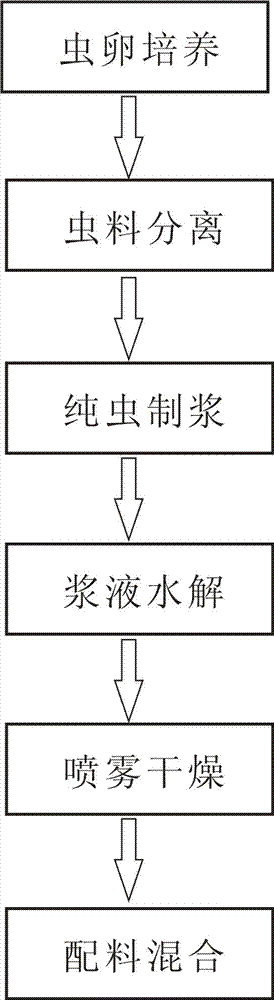

[0016] Such as figure 1 As shown, the protein feed production process produced by insects comprises the following steps:

[0017] A. Cultivation of worm eggs: putting the worm eggs bred by barley worms into microbial feed for cultivation;

[0018] B. Separation of insect material: after the eggs form pure insects, separate the pure insects from the microbial feed;

[0019] C. Pure worm refining: After high-temperature disinfection of pure worm, grind it into slurry;

[0020] D. Hydrolysis: add neutral protease to the slurry to seal the hydrolysis, the hydrolysis time is up to 50 hours, or 46 hours or 48 hours, and the temperature is controlled at 50°C;

[0021] E. Drying: spray-dry the hydrolyzed slurry at high temperature to form pure insect plasma protein powder;

[0022] F. Mixing ingredients: Mix the pure worm pulp protein powder and the pulverized microbial feed in equal parts by weight, and stir evenly, and the worm peptide protein for biological feed is prepared.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com