Nano-silver emulsifiable paste and its preparation method

A nano-silver, cream technology, applied in the field of medicine, can solve the problems of increasing medical costs, shortage of medical resources, heavy economic burden on patients and families, etc., to restore the health of the wounded, reduce combat attrition, and promote wound healing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

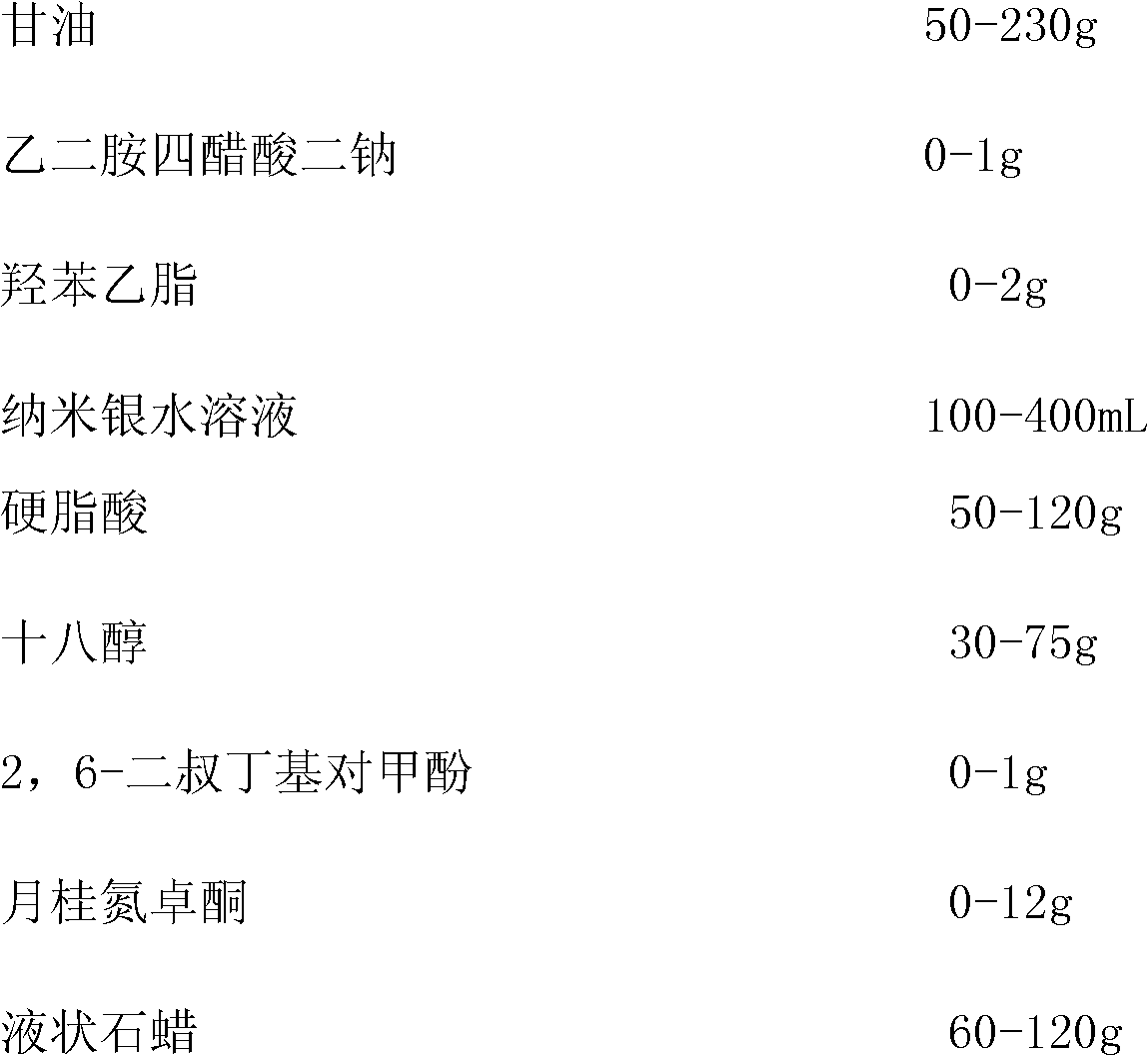

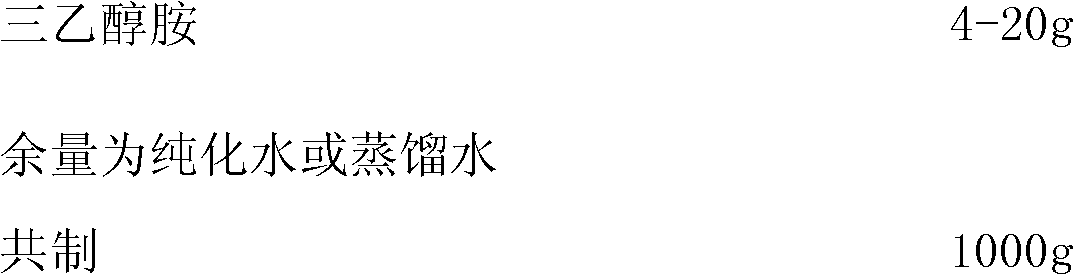

Method used

Image

Examples

Embodiment 1

[0039] Components and content of nano silver cream: 59.1g stearic acid, 59.1g stearyl alcohol, 118.2g liquid paraffin, 0.5g ethylparaben, 4.6g triethanolamine, 10.1g laurocaprolactone, 2,6- Di-tert-butyl-p-cresol 0.5g, edetate disodium 0.5g, glycerin 228g, nano-silver solution 232.6mL, add water to 1000g.

[0040] Preparation:

[0041] (1) Preparation of water phase: Add glycerin, disodium edetate and ethylparaben into an appropriate amount of nano-silver solution, heat to 80°C, stir well, and set aside.

[0042] (2) Oil phase preparation: Mix stearic acid, stearyl alcohol, 2,6-di-tert-butyl-p-cresol, laurocaprazine and liquid paraffin, heat to 75°C, and stir well.

[0043] (3) Immediately add the water phase to the oil phase, then add triethanolamine, stop heating, stir rapidly immediately, and when the temperature drops to 50°C, continue stirring until it coagulates to obtain nano silver cream.

Embodiment 2

[0045] Components and content of nano silver cream: 59.1 g of stearic acid, 59.1 g of stearyl alcohol, 118.2 g of liquid paraffin, 4.6 g of triethanolamine, 228 g of glycerin, 200 mL of nano silver liquid, and add water to 1000 g.

[0046] Preparation:

[0047] (1) Preparation of water phase: Mix glycerin and nano-silver solution, heat to 80°C, stir well, and set aside.

[0048] (2) Preparation of oil phase: Mix stearic acid, stearyl alcohol and liquid paraffin, heat to 75°C, stir well, and set aside.

[0049] (3) Immediately add the water phase to the oil phase, then add triethanolamine, stop heating, stir rapidly immediately, and when the temperature drops to 50°C, continue stirring until it coagulates to obtain nano silver cream.

Embodiment 3

[0051] Components and content of nano silver cream: 59.1g stearic acid, 59.1g stearyl alcohol, 118.2g liquid paraffin, 4.6g triethanolamine, 10.1g laurocapram, 2,6-di-tert-butyl p-cresol 0.5g, 0.5g disodium edetate, 228g glycerin, 300mL nano-silver solution, add water to 1000g.

[0052] Preparation:

[0053] (1) Preparation of water phase: Mix glycerin, disodium ethylenediaminetetraacetic acid, and nano-silver solution, heat to 80°C, stir well, and set aside.

[0054] (2) Oil phase preparation: Mix stearic acid, stearyl alcohol, 2,6-di-tert-butyl-p-cresol, laurocaprazine and liquid paraffin, heat to 75°C, stir well, and set aside.

[0055] (3) Immediately add the water phase to the oil phase, then add triethanolamine, stop heating, stir rapidly immediately, and when the temperature drops to 50°C, continue stirring until it coagulates to obtain nano silver cream.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com