High-frequency centrifugal reverse molding machine

A technology of reverse molding and rotating motors, which is applied to centrifuges and other directions, and can solve problems such as expensive components and bulky machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

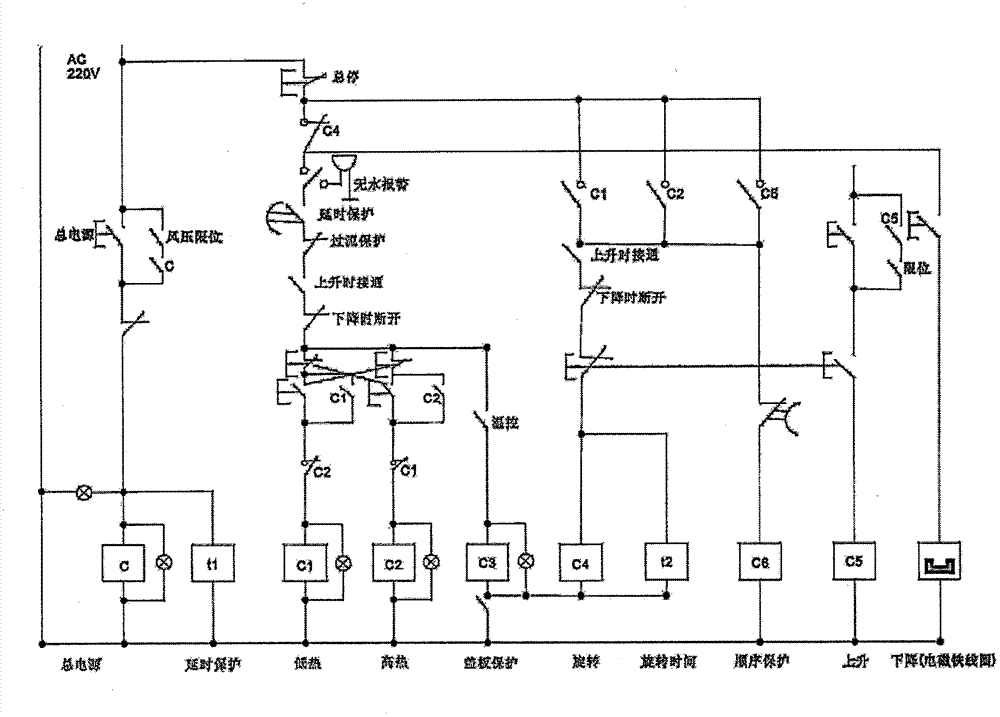

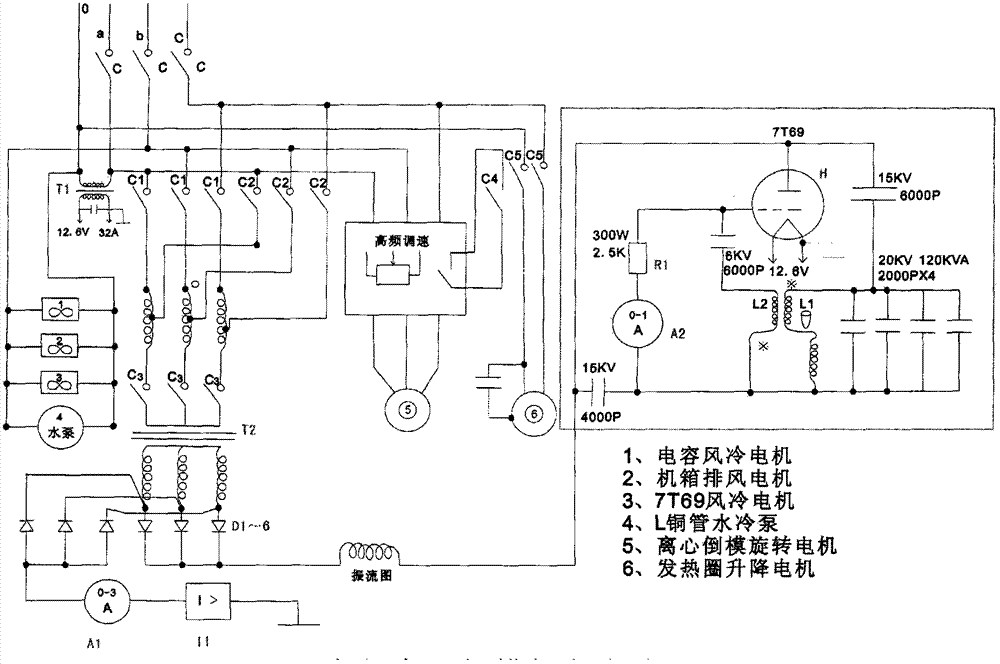

[0014] figure 1 The main circuit diagram of the centrifugal pouring machine of the present invention is shown, as figure 1 as shown,

[0015] The main circuit includes main power contactor C, transformer T1 and 7T69 electron tube, main power contactor C and T1 provide 12.6V filament voltage for transformer to 7T69 electron tube.

[0016] The main circuit also includes a transformer T2, rectifier diodes D1, D2, D3, D4, D5, D6 and rectifier coils, the transformer T2 is connected to the rectifier diodes D1, D2, D3, D4, D5 and D6 respectively and then connected to the rectifier coil, the above Transformer T2, rectifier diodes D1, D2, D3, D4, D5, D6 and rectifier coil constitute a three-phase full-wave rectifier circuit.

[0017] The main circuit also includes three low thermal contactors C1, three high thermal contactors C2, three rectification circuit main contactors C3, full wave rectification circuit output ammeter A1 and overcurrent protection relay I1, three low thermal con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com