Molding method of long fiber reinforced thermoplastic resin

A technology of reinforced resin and molding method, which is applied in the molding field of long fiber reinforced thermoplastic resin, which can solve the problems of production interruption, fiber dispersion, and high resin viscosity requirements, and achieve the effect of expanding the molding range and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

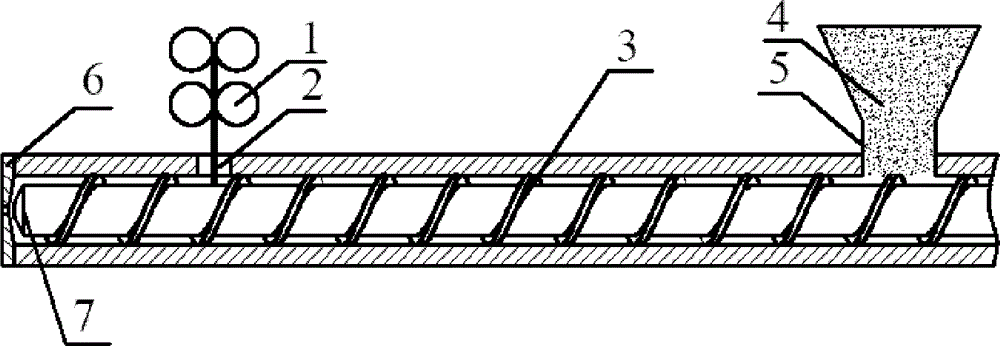

Embodiment 1

[0019] Feed the long glass fiber bundles through the fiber feeding port (2) of the barrel, the fiber feeding port (2) is located directly above the barrel, and the distance from the screw outlet is 6D (D is the diameter of the screw), and the long glass fiber The bundle is brought into the screw under the rotation of the twin-screw extruder (3), and the thermoplastic resin polypropylene (melt flow index is 3.2g / 10min) is fed through the hopper (5) and melted and plasticized by the screw , the long glass fiber bundles are cut into 20mm under the gentle shearing action of the screw, and mixed evenly with the thermoplastic resin polypropylene, and finally molded by the sheet mold element (6) to obtain a long glass fiber reinforced polypropylene sheet; wherein, the continuous The screw element after the long fiber is fed is a double-head conveying element with a lead of 2D. The temperature settings of the extruder are respectively set from the feeding port to the outlet: 170°C-190...

Embodiment 2

[0023] Feed the long glass fiber bundles through the fiber feeding port (2) of the barrel, the fiber feeding port (2) is located directly above the barrel, and the distance from the screw outlet is 7D (D is the diameter of the screw), the long glass fiber The beam is brought into the screw under the rotation of the twin-screw extruder (3), and the thermoplastic resin polypropylene (melt flow index is 50g / 10min) is fed through the hopper (5) and melted and plasticized by the screw, The long glass fiber bundles are cut into 30 mm under the gentle shearing action of the screw, and mixed evenly with the thermoplastic resin polypropylene, and finally molded by the granulation mold element (6) to obtain long glass fiber reinforced polypropylene particles; wherein, the long glass fiber bundles The screw element after the glass fiber is fed is a double-head conveying element with a lead of 1.6D. The temperature settings of the extruder are respectively set from the feeding port to the...

Embodiment 3

[0027] Feed the long glass fiber bundles through the fiber feeding port (2) of the machine barrel, the fiber feeding port (2) is located directly above the machine barrel, and the distance from the screw outlet is 6.5D (D is the diameter of the screw), and the long glass fiber The fiber bundle is brought into the screw under the rotation of the twin-screw extruder (3), and the thermoplastic resin polyoxymethylene (melt flow index is 9.7g / 10min) is fed through the hopper (5) and melted by the screw. The long glass fiber bundle is cut into 28mm under the gentle shearing action of the screw rod, and mixed evenly with the thermoplastic resin polyoxymethylene, and finally molded by the plate mold element (6) to make a long glass fiber reinforced polyoxymethylene sheet; wherein, The screw element after the long glass fiber is fed is a double-head conveying element with a lead of 1.5D. The temperature settings of the extruder are respectively set from the feeding port to the outlet: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com