Roof hoisting apparatus based on whole life cycle of building and introduced from exterior wall of construction part

A technology of whole life cycle, lifting equipment, applied in the direction of trolley crane, crane, transportation and packaging, etc., can solve the problems of unusable, easy to damage, high requirements on the work site, etc., to reduce the impact and facilitate the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

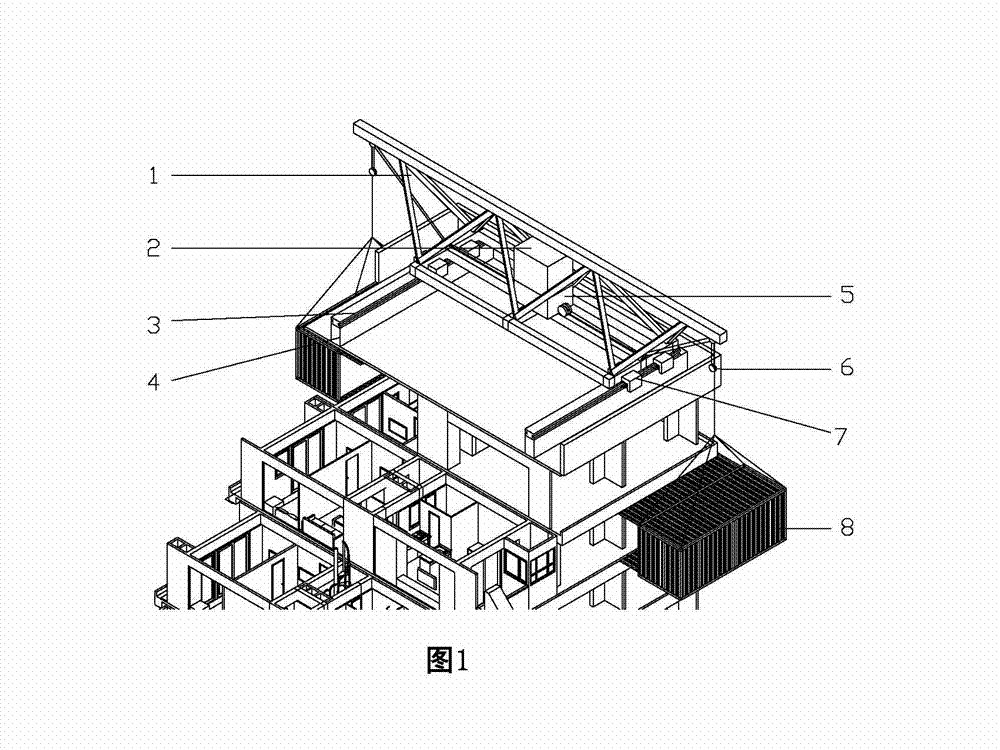

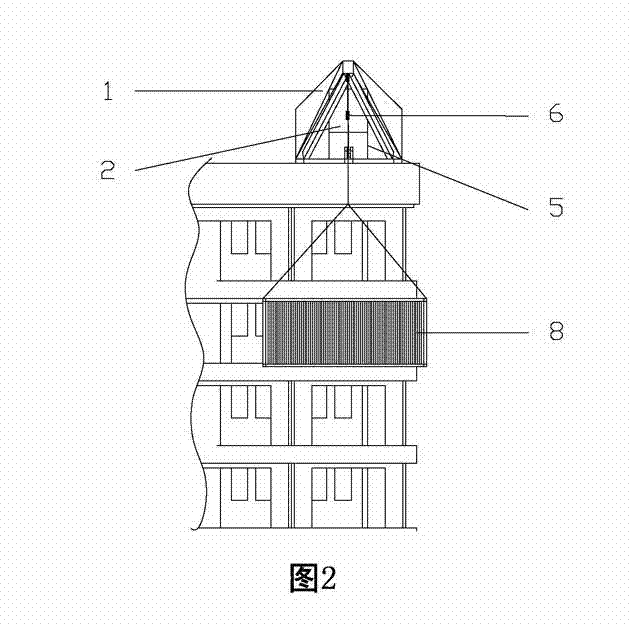

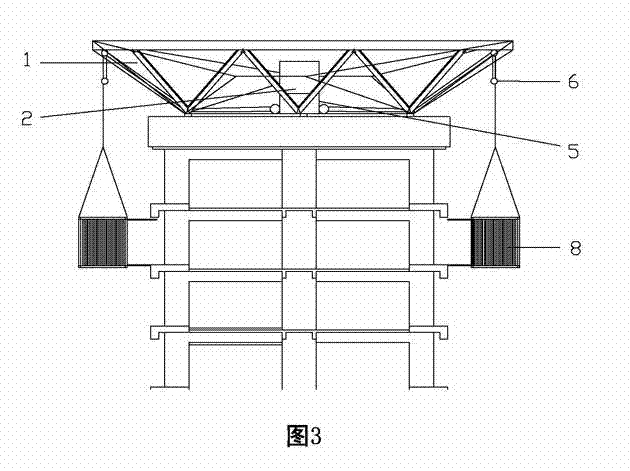

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention is based on the roof lifting equipment imported from the exterior wall of building parts in the whole life cycle of the building. A base 4 is provided on both sides of the roof of the finished building, and each base 4 is provided with a guide rail 3, two A set of moving devices 7 are arranged symmetrically on the root guide rails 3, and a working cabin 1 is supported and fixed on the two sets of moving devices 7. Each of the two hoisting devices 6 is articulated with a container 8. An operation room 2 is arranged in the operation cabin 1. A power unit 5 is arranged below the operation room 2. The operation panel of the operation room 2 is connected with the mobile device 7 through electric wires. The operating panel of the chamber 2 is jointly formed by connecting the electric wire, the power unit 5 and the steel wire rope with the hoisting equipment 6 .

[0025] The base 4 is on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com