Method for olefin isomerization

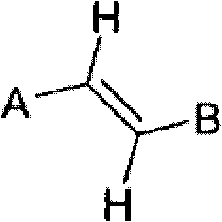

A technology of olefin and configuration, applied in the field of preparation of E-configuration alkenyl compounds, can solve problems such as insufficient to avoid separation of Z isomer and other by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

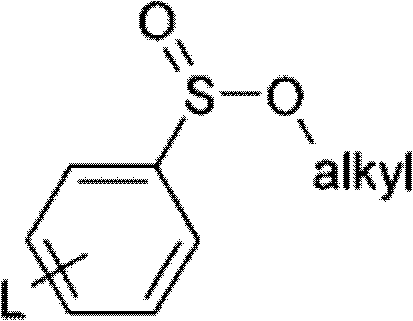

Method used

Image

Examples

Embodiment 1

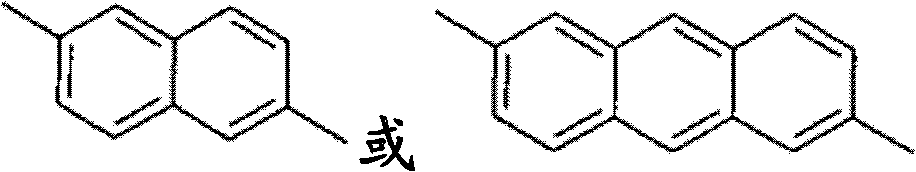

[0086]

[0087] 67 g of p-toluenesulfinic acid Na salt, 435 g of compound 1a / b (crude, from the Wittig reaction) and 784 g of n-heptane were initially introduced into a 4 L stirring apparatus. 57.0 g of hydrochloric acid (25%), 351.7 g of water and 87.1 g of ethanol were added to the suspension.

[0088] The suspension was warmed to 81 °C with stirring. A clear phase appeared at 70°C. After 3.5 h, the still-hot lower aqueous phase was separated. The organic phase was then passed through with 250 g of NaHCO 3 The solution was washed with stirring for 30 min, and the aqueous phase was separated (pH=8). The organic phase was finally washed again by shaking with 250 ml of water, and the aqueous phase was separated again (pH=7). Heptane was distilled off from the organic phase to obtain a residue (isomer distribution 85:15 E / Z, cyclohexane rings all in 1,4-trans configuration, about 1.6% of cis-configured rings present hexane ring).

[0089] The residue comprising 1a / b is ...

Embodiment 2

[0108]

[0109] Compound 2a / b having a crude content of 75:25 (E / Z) obtained by isomerization analogously to Example 1 with sulfinic acid was modified at about 25° C. in an apparatus as in Example 1 Irradiate for 27h.

[0110] The resulting isomer ratio: 94:6 (E / Z).

Embodiment 3

[0112]

[0113] The reaction was carried out analogously to Example 1.

[0114] The resulting isomer ratio: 94:6 (E / Z).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| isotropization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com