Preparation method of azilsartan intermediate

A compound and reaction temperature technology, applied in the field of preparation of azilsartan intermediates, can solve the problems of increased synthesis cost, low yield, and difficulty in obtaining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

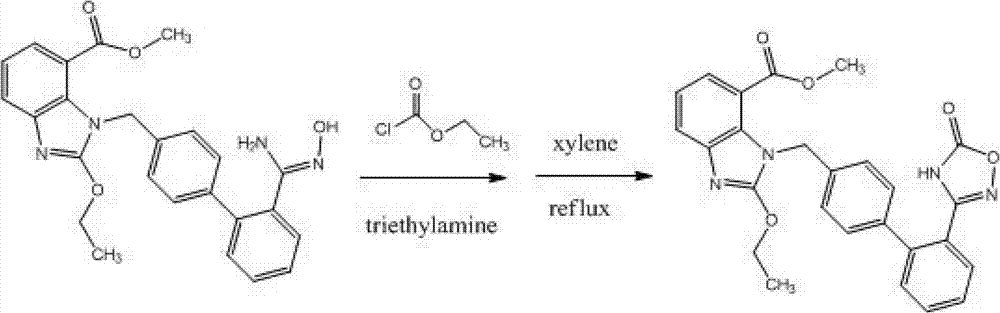

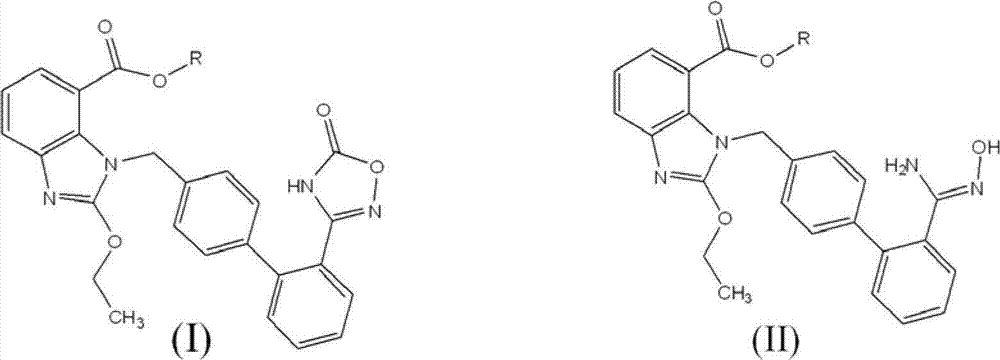

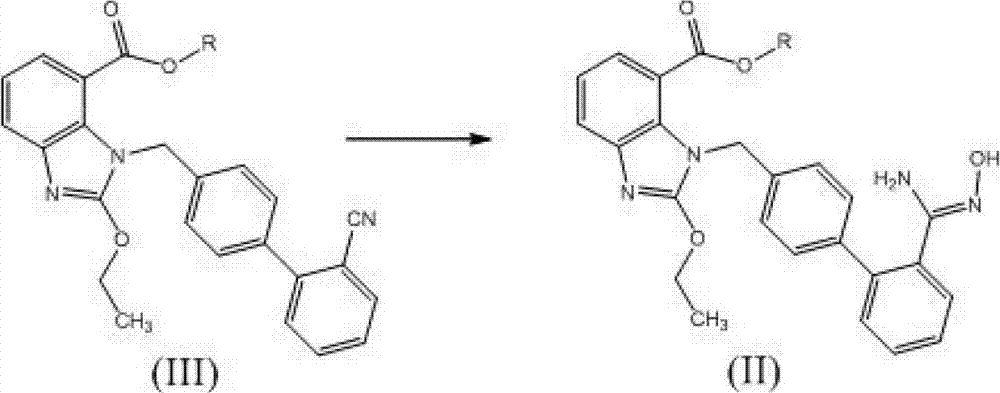

Method used

Image

Examples

Embodiment 1

[0034] 1.0 g (2.25 mmol) of 2-ethoxy-1-[(2'-(hydroxyamidino)biphenyl-4-yl)methyl]-1H-benzimidazole-7-carboxylic acid methyl ester (ie The compound represented by formula II) was added to a 50ml three-neck flask, dissolved in 20ml tetrahydrofuran, then added 0.37g (2.25mmol) N,N'-carbonyldiimidazole, heated to reflux (at a temperature of about 66°C) for 16 hours, cooled, The solvent was distilled off under reduced pressure, 30ml of water was added to the residue, extracted with dichloromethane (30ml×3), and the obtained dichloromethane solution was dried over anhydrous sodium sulfate. The solvent was distilled off under reduced pressure to obtain 0.74 g of the compound represented by formula I, with a yield of 70%.

[0035] 1 HNMR (CDCl3): δ1.447(3H, s), δ3.687(3H, s), δ4.484(2H, s), δ5.638(2H, s), δ6.950-7.882(11H, m ),δ9.38(1H,brs)

Embodiment 2

[0037] 10.0 g (22.5 mmol) of 2-ethoxy-1-[(2'-(hydroxyamidino)biphenyl-4-yl)methyl]-1H-benzimidazole-7-carboxylic acid methyl ester (ie The compound represented by formula II) was added to a 250ml three-neck flask, dissolved in 100ml tetrahydrofuran, and then 3.7g (22.5mmol) N,N'-carbonyldiimidazole and 3.4g (22.5mmol) 1,8-diazabicyclo [5.4.0] Undec-7-ene (DBU), heated to reflux (about 66°C) for 6 hours, evaporated the solvent under reduced pressure, added 100ml of water to the residue, and dichloromethane (100ml×3 ) extraction, the obtained dichloromethane solution was dried with anhydrous sodium sulfate, and the solvent was evaporated under reduced pressure to obtain 8.6 g of the compound shown in formula I, yield: 81%.

Embodiment 3

[0039] 10.0g (22.5mmol) 2-ethoxy-1-[[2'-(hydroxyamidino)[1,1'-biphenyl]-4-yl]methyl]-1H-benzimidazole- Add methyl 7-carboxylate (the compound represented by formula II) into a 250ml three-neck flask, dissolve it with 100ml acetonitrile, add 3.7g (22.5mmol) carbonyldiimidazole and 3.4g (22.5mmol) DBU, and stir the reaction at room temperature overnight , evaporated the solvent under reduced pressure, added 100ml of water to the residue, extracted with dichloromethane (100ml×3), and dried the obtained dichloromethane solution with anhydrous sodium sulfate. The solvent was distilled off under reduced pressure to obtain 7.9 g of the compound represented by formula I, yield: 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com