Polyolefin catalyst adopting carbon nanotubes as carriers and preparation method thereof

A carbon nanotube and catalyst technology, applied in the field of polyolefin catalyst and its preparation, can solve the problems of technical difficulty, high price and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

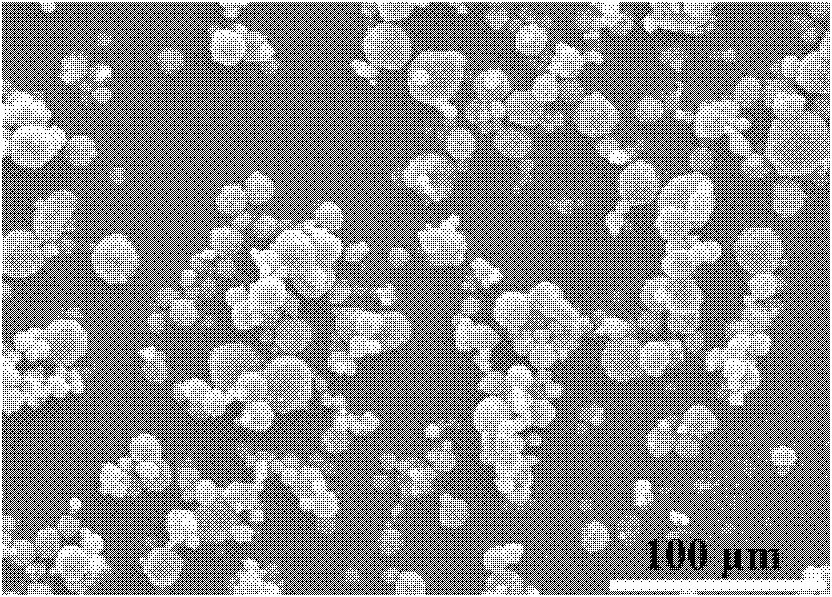

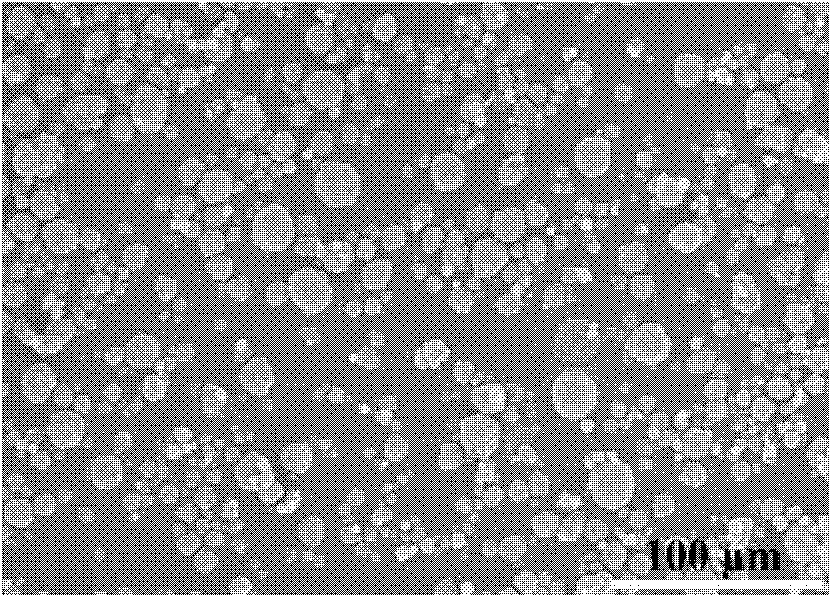

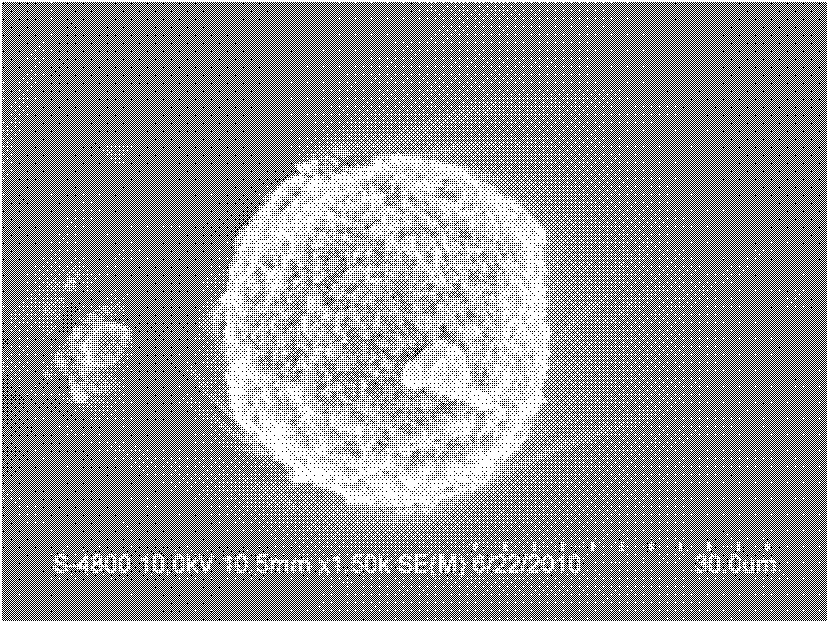

Image

Examples

Embodiment 1

[0064] 1) Disperse 1.0 gram (0.083mol) of carbon nanotube catalyst support in 50ml of ether under a nitrogen atmosphere, and then add 0.83molC 4 h 9 50ml of ether solution of MgBr was added dropwise to the suspension of carbon nanotubes, refluxed at 40°C for 10.0 hours, after the reaction was completed, washed with ether for 5 times, and dried to obtain 0.90g of magnesium composites supported by carbon nanotube catalysts . Wherein, the mass percent content of magnesium element is 3.28wt%.

[0065] 2) Take 0.5 grams (0.042mol) of the magnesium composite of the carbon nanotube catalyst carrier prepared in step 1) at -20°C and disperse it in 10ml of transition metal compound Ziegler-Natta catalyst titanium tetrachloride and react for 2.0 hours, and slowly heat up to At 80°C, add 0.10 g (0.35 mmol) of dibutyl phthalate as an auxiliary agent, continue to heat up to 120°C and react for 2.0 hours. After the reaction is completed, filter, wash with hexane for 3 to 6 times, and dry t...

Embodiment 2

[0072] 1) Disperse 10.0 grams (0.83mol) of carbon nanotube catalyst carrier in 50ml of tetrahydrofuran under nitrogen atmosphere, and then add 8.3molC 4 h 9 The 50ml tetrahydrofuran solution of MgCl was added dropwise in the suspension of carbon nanotubes, refluxed at a constant temperature at 70°C for 20.0 hours, after the reaction was completed, washed 5 times with tetrahydrofuran, and dried to obtain the magnesium composite (-OMgCl ). Wherein, the mass percent content of magnesium element is 5.0wt%.

[0073] 2) Take 5.0 grams (0.42mol) of the magnesium composite of the carbon nanotube catalyst carrier prepared in step 1) at -20°C and disperse it in 100ml of transition metal compound Ziegler-Natta catalyst titanium tetrachloride and react for 1.0 hour, and slowly heat up to Add 0.24 g (1.0 mmol) of auxiliary agent fluorene diether at 60°C, continue to heat up to 120°C and react for 1.0 hour. After the reaction is completed, filter, wash with hexane for 3 to 6 times, and dr...

Embodiment 3

[0079] 1) Disperse 1.0 g (0.083 mol) of carbon nanotube catalyst carrier in 50 ml of tetrahydrofuran under a nitrogen atmosphere, and then add 0.05 mol of C 4 h 9 The 50ml tetrahydrofuran solution of MgBr is added dropwise in the suspension of carbon nanotubes, 10.0 hours of constant temperature reflux reaction at 130 ℃, after reaction is finished, use tetrahydrofuran to wash 5 times, obtain the magnesium complex (OMgBr of carbon nanotube catalyst carrier after drying) ). Wherein, the mass percentage content of magnesium element is 1.5wt%.

[0080] 2) Take 0.5 g (0.042 mol) of the magnesium composite of the carbon nanotube catalyst carrier prepared in step 1) at -20°C and disperse it in 10 ml of transition metal compound Ziegler-Natta catalyst titanium tetrachloride for 2.0 hours, and heat up to 120 react at ℃ for 1.0 hour, and after the reaction is completed, filter, wash with hexane for 3 to 6 times, and dry to obtain a transition metal titanium catalyst supported by carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com