Washing optimizing method and device of low-temperature multi-effect evaporation seawater desalting device

A multi-effect evaporation and optimization device technology, applied to chemical instruments and methods, cleaning methods and utensils, evaporator accessories, etc., can solve problems such as unsatisfactory evaporators, undesigned pickling, equipment corrosion, etc., and shorten the cleaning time , Reduce cleaning costs and simplify cleaning procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

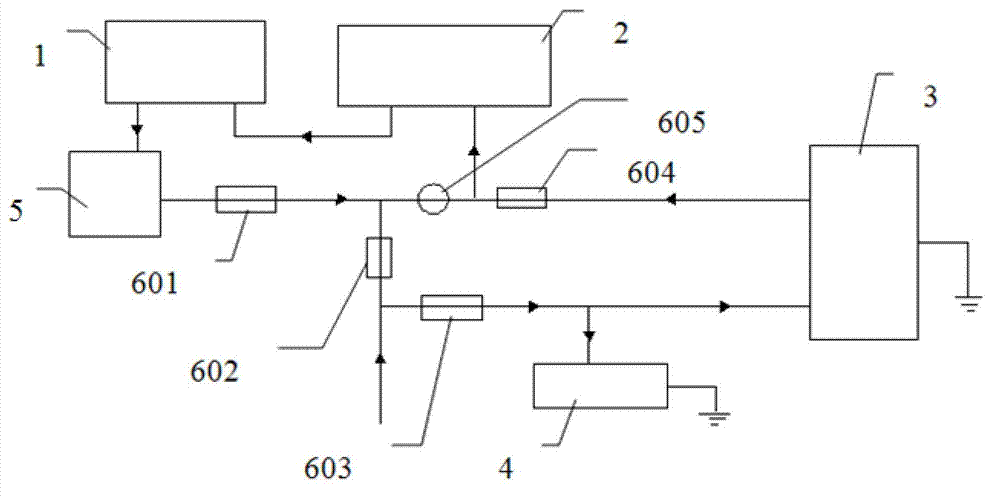

[0014] Such as figure 1 As shown, the present invention provides a cleaning optimization device for a low-temperature multi-effect evaporation seawater desalination device, including an evaporator 1, a condenser 2, a heat exchanger 3, a three-stage pump 4, a pickling system 5, and connecting the above-mentioned equipment The pipeline and the first to fourth valves on the pipeline, the fifth valve 605 is also set on the pipeline between the condenser 2 inlet regulating valve (second valve 602 ) and the condenser inlet, and the fifth valve can be a manual regulating valve.

[0015] The cleaning optimization method of the low-temperature multi-effect evaporation seawater desalination device: close the fifth valve 605 during pickling, so that the pickling system 5, heat exchanger 3, condenser 2, and evaporator 1 form a pickling cycle, and carry out comprehensive pickling Washing; rinse immediately after pickling, open the fifth valve 605, so that seawater directly flows into the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com