High-extrusion resistance special threaded connection joint for sleeve pipes

A special thread and casing connection technology, used in casing, drill pipe, drilling equipment and other directions, can solve the problems of weak torque resistance, low connection strength, poor sealing performance, etc., to increase connection strength and increase anti-compression load. capacity and torque resistance, the effect of improving crush resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

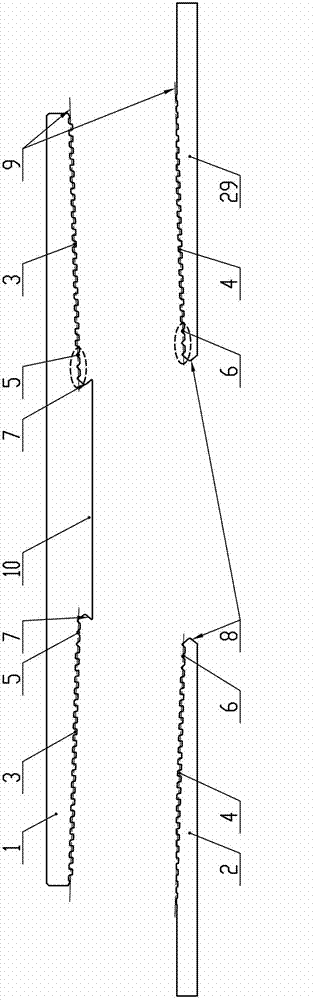

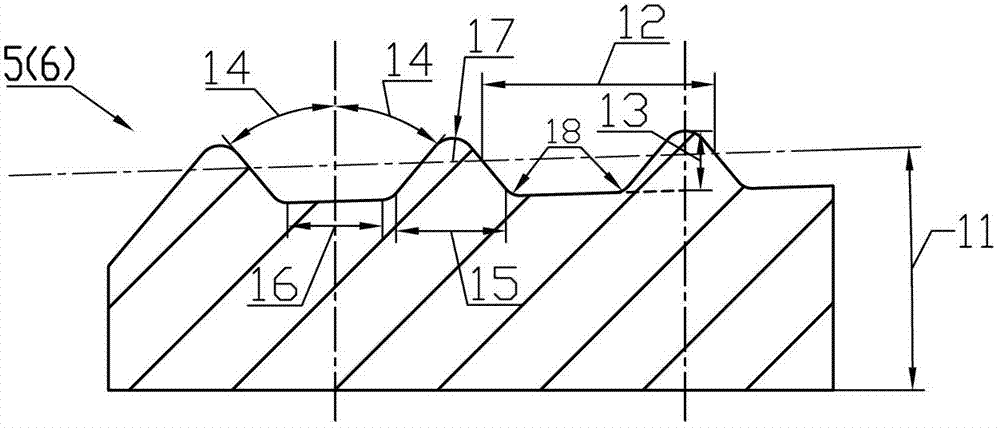

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] Figure 1~Figure 5 Among them, including coupling 1, pipe body 2, internal thread 3, external thread 4, internal dome thread 5, external dome thread 6, internal torque shoulder 7, external torque shoulder 8, pitch line 9, coupling Inner shoulder plane 10, taper 11, pitch 12, tooth height 13, flank angle 14, tooth width 15, tooth width 16, tooth arc 17, plane transition arc 18, tooth bottom to inner platform Shoulder plane thickness 19, tooth top to tube inner wall thickness 20, inner shoulder end thickness 21, outer shoulder end thickness 22, inner shoulder apex to shoulder plane thickness 23, outer shoulder apex to inner tube inner wall thickness 24. Inner shoulder apex radius 25, outer shoulder apex radius 26, inner shoulder angle 27, outer shoulder angle 28, pipe body 29, etc.

[0018] Such as figure 1 , figure 2 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com