Full-automatic oil injection system of high-pressure compressor

A high-pressure compressor, fully automatic technology, used in machines/engines, mechanical equipment, liquid variable capacity machinery, etc., can solve problems affecting industrial hygiene, insufficient cylinder oil injection, waste of lubricating oil, etc., to avoid subjective intervention and Judging, avoiding abnormal injection, and ensuring the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

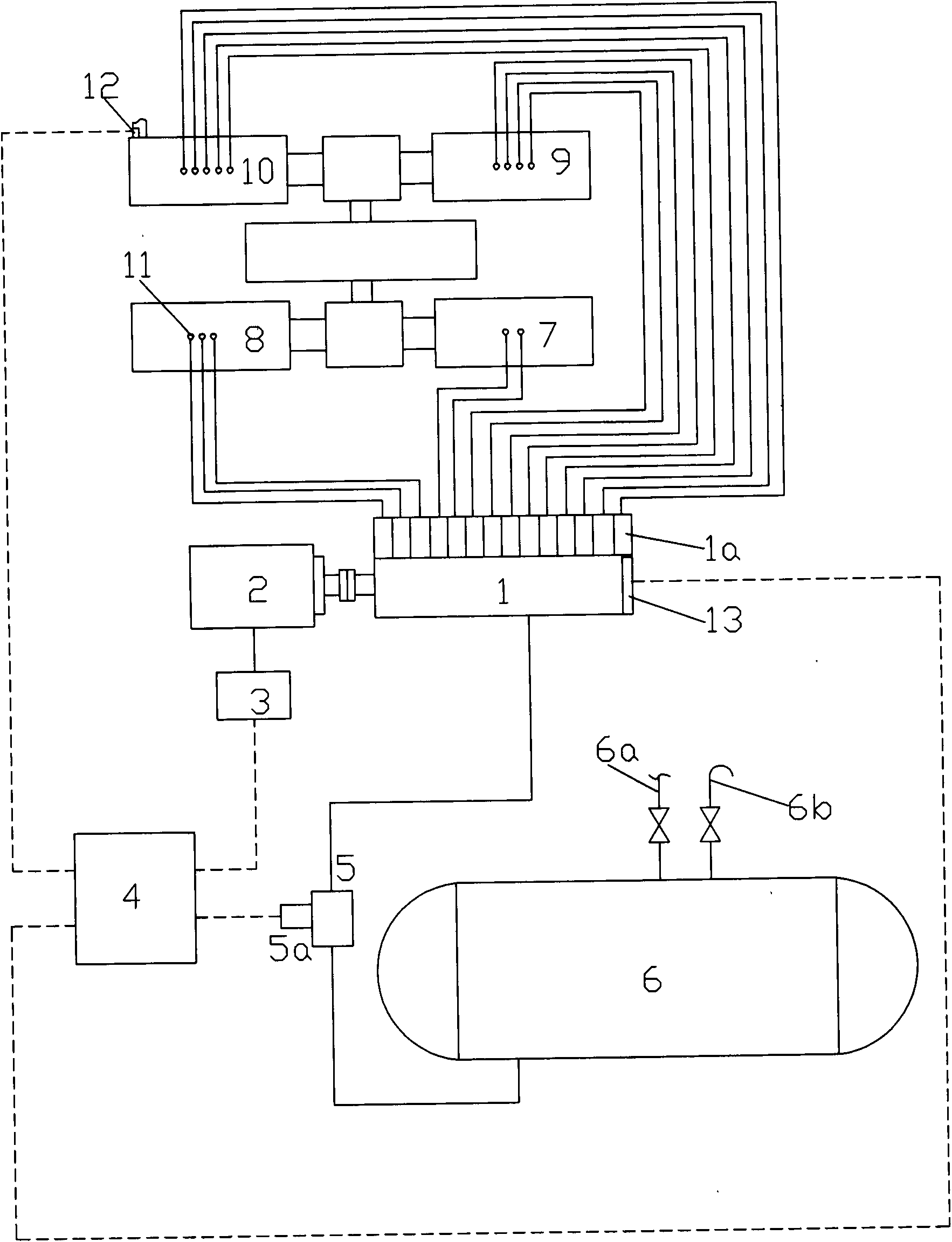

[0018] Accompanying drawing is the structural representation of the present invention, and the high-pressure compressor full-automatic oil injection system of the present invention comprises oil storage tank 6, oiler 1 and the oil injection point 11 that is distributed on the compressor cylinder, and described oiler 1 is connected with oil injection point 11 one-to-one corresponding oil injection pump 1a, the oil inlet of the oil injector 1 is directly connected with the oil delivery port of the oil storage tank; it also includes an automatic control system;

[0019] The automatic control system includes:

[0020] The pressure sensor 12 is arranged at the final outlet of the compressor for collecting pressure data at the final outlet of the compressor;

[0021] The oil injector liquid level sensor 13 is used to collect the oil level data of the oil injector 1;

[0022] The solenoid valve 5 is installed between the oil inlet of the oil injector 1 and the oil delivery port of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com