Dustproof pellicle component frame, manufacturing method thereof and dustproof pellicle component

A technology for dust-proof film components and frames, which is applied in the photoengraving process of the pattern surface, the original for photomechanical processing, optics, etc., to achieve the reduction of shedding and dust generation, and it is not easy to crack and spread, deform and flex. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Hereinafter, examples of the present invention will be described in detail, but the scope of the present invention is not limited to these examples.

[0052] (Example 1)

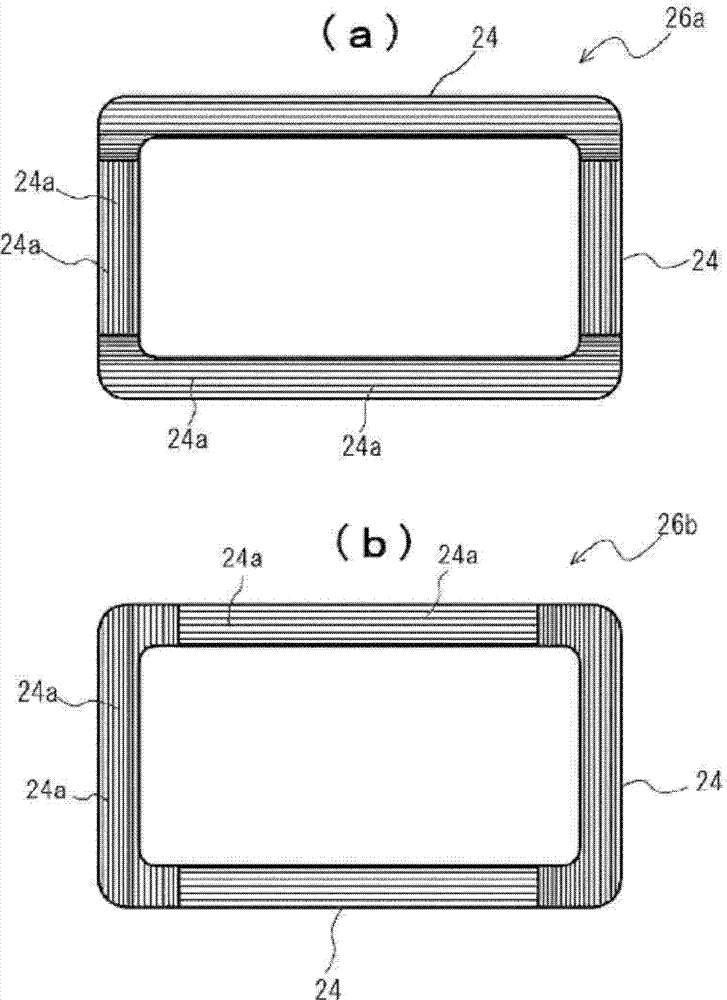

[0053] Such as Figure 4As shown, an impregnated elongated sheet-shaped body 30 (prepreg) obtained by impregnating a plurality of long-fibrous carbon fibers 24a distributed in the longitudinal direction with epoxy resin (trade name; Daiyali -ド) HYEJ25M80D, manufactured by Mitsubishi Plastics Corporation). As the main part of the pellicle frame 10, the sheet-shaped bodies 30a, 30d forming the long sides have dimensions of 1780×50 mm and 1680×50 mm. In addition, as the main part of the pellicle frame 10, the sheet-shaped bodies 30b and 30c forming the short sides have dimensions of 1460×50mm and 1560×50mm. The sheets 30a, 30b, 30c, 30d are stacked on Figure 7 The groove portion 38 of the lamination jig 36 made of aluminum alloy is shown. At this time, the formation of gaps should be avoided as muc...

Embodiment 2

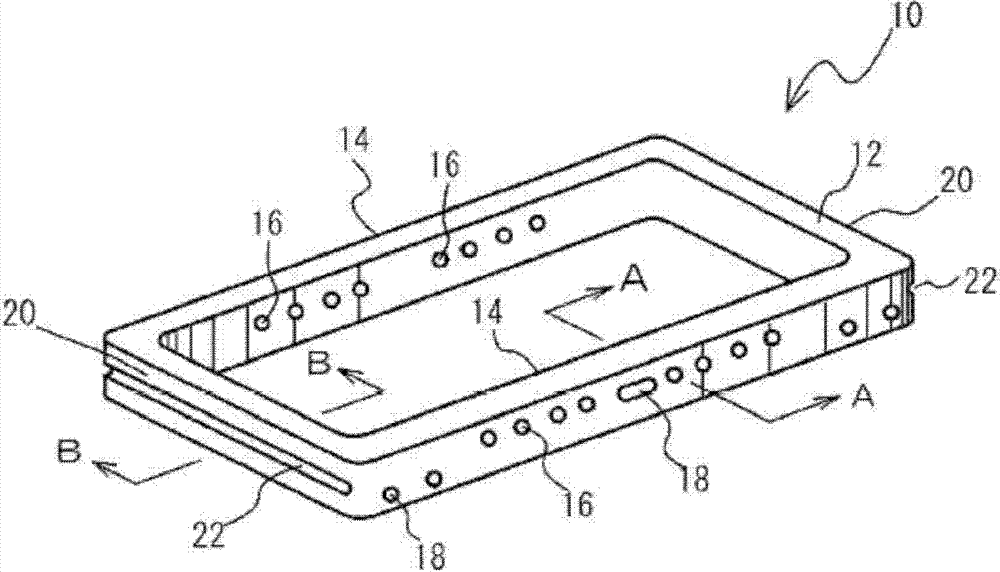

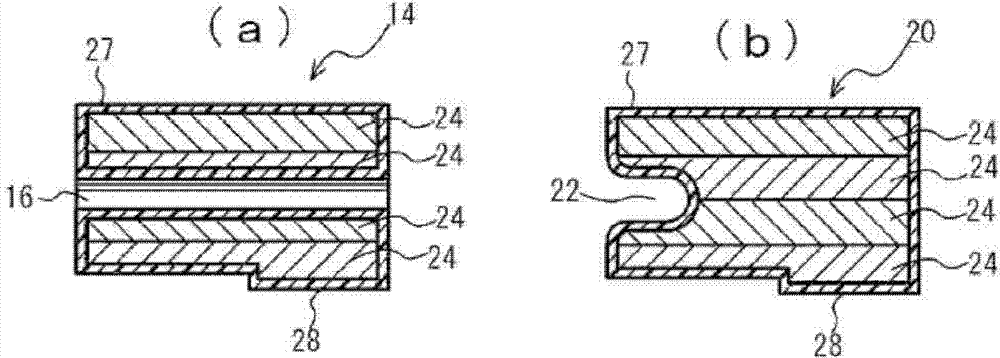

[0059] Using the laminated body 34 formed in the same manner as in Example 1 with an outer dimension of 920×770mm, an inner dimension of 870×720mm, and a thickness of 6.2mm, the outer dimension is 904.5×750mm, the inner dimension is 894.5×738mm, the height is 5.8mm, and the outer dimension of the corner is R6mm. , an inner dimension R2mm, and a dust-proof film assembly frame 10 with four ventilation holes 16 with a diameter of 1.5mm arranged on each long side. The pellicle frame 10 was washed and dried in the same manner as in Example 1, and an acrylic resin (trade name; ST Sater's (Erecoat ST Satyina, manufactured by Shimizu Co., Ltd.) Apply by electrocoating to form a resin film 27. Further, the pellicle frame 10 is washed with a surfactant and pure water, and after drying, the same as in Example 1, on the pellicle frame 10. The sticking surface 12 and the step surface 28 form a pellicle adhesive layer and a photomask adhesive layer 46 respectively, and a peeling sheet 48 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com