Method for manufacturing fused zirconia corundum basin brick die

A technology of fused zirconium and material basin, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of low yield, difficulty in forming special-shaped fused zirconium corundum bricks, waste of raw materials, etc., so as to improve the yield and improve the later stage. Processing efficiency, the effect of avoiding contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

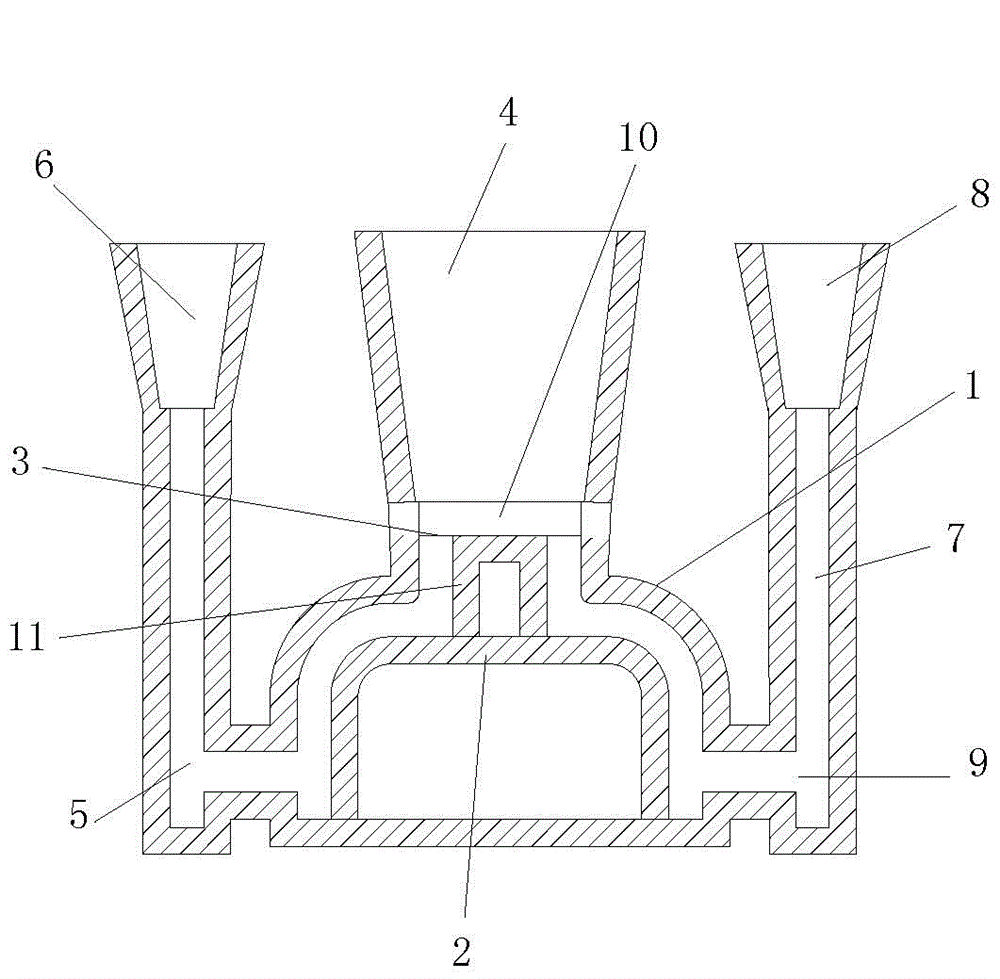

[0008] The present invention includes an outer mold, an inner mold and an inner core. The inner core 11 is placed at the center of the upper part of the inner mold. The inner mold, the inner core and the outer mold are concentrically placed in the outer mold. The inner core, the inner mold and the outer mold are made of resin sand. , the two sides of the outer mold 1 respectively have an exhaust duct 5 and a pouring duct 7 that communicate with the brick-shaped cavity formed between the inner mold 2 and the outer mold 1 through the casting port 9, and the upper part of the vertical exhaust duct has a row Gas riser 6, casting riser 8 on the upper part of the vertical casting duct, loose layer 10 above the cutting line 3 on the upper part of the outer mold, insulation riser 4 placed on the loose layer, exhaust duct, exhaust riser a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com