Preparation method of hydrophobic silica fiber film and use of the hydrophobic silica fiber film in removal of organic pollutants

A technology of organic pollutants and silicon dioxide, applied in the direction of silicon dioxide, silicon oxide, silicon compounds, etc., can solve the problem of chemical inertness of silicon dioxide fiber membrane, and achieve the effect of mild conditions and enhanced ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

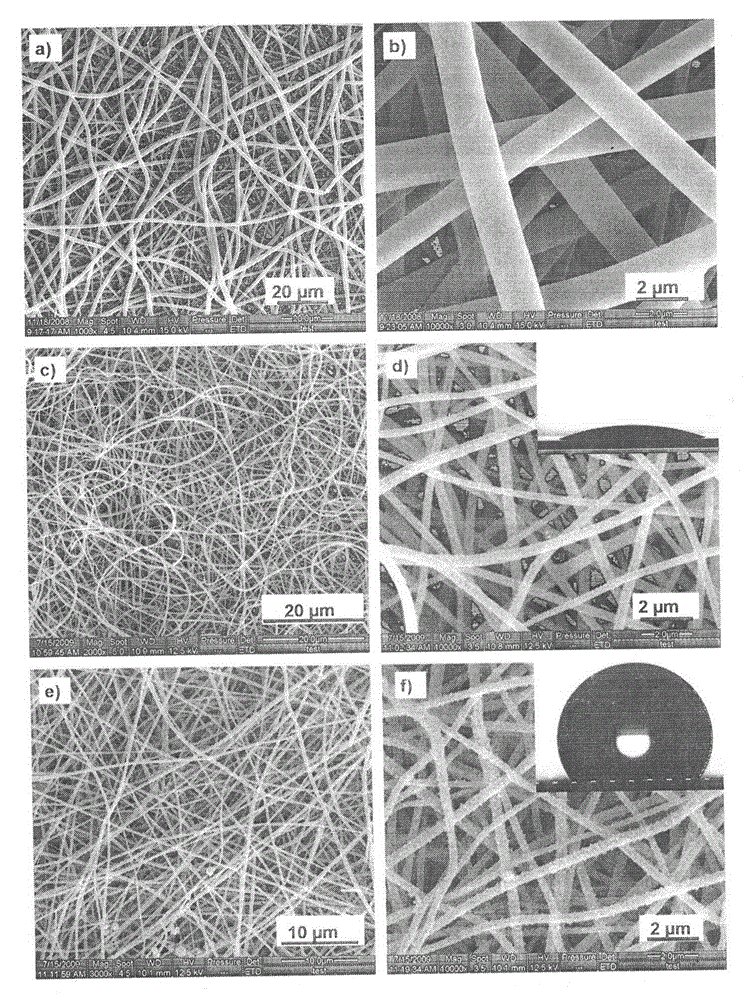

[0015]Specific embodiment one: the preparation method of hydrophobic silicon dioxide nanofiber film is carried out as follows: 1. take the silane of band functional group and solvent, wherein the silane of band hydrophobic functional group: the volume ratio of solvent is 1: 10 to 1800, mix the silane with hydrophobic functional groups and the solvent to form a silane solution; 2. Immerse the silica nanofiber membrane in the silane solution prepared in step 1, react for 1 to 30 hours, and take it out to obtain a hydrophobic Silica nanofiber membrane.

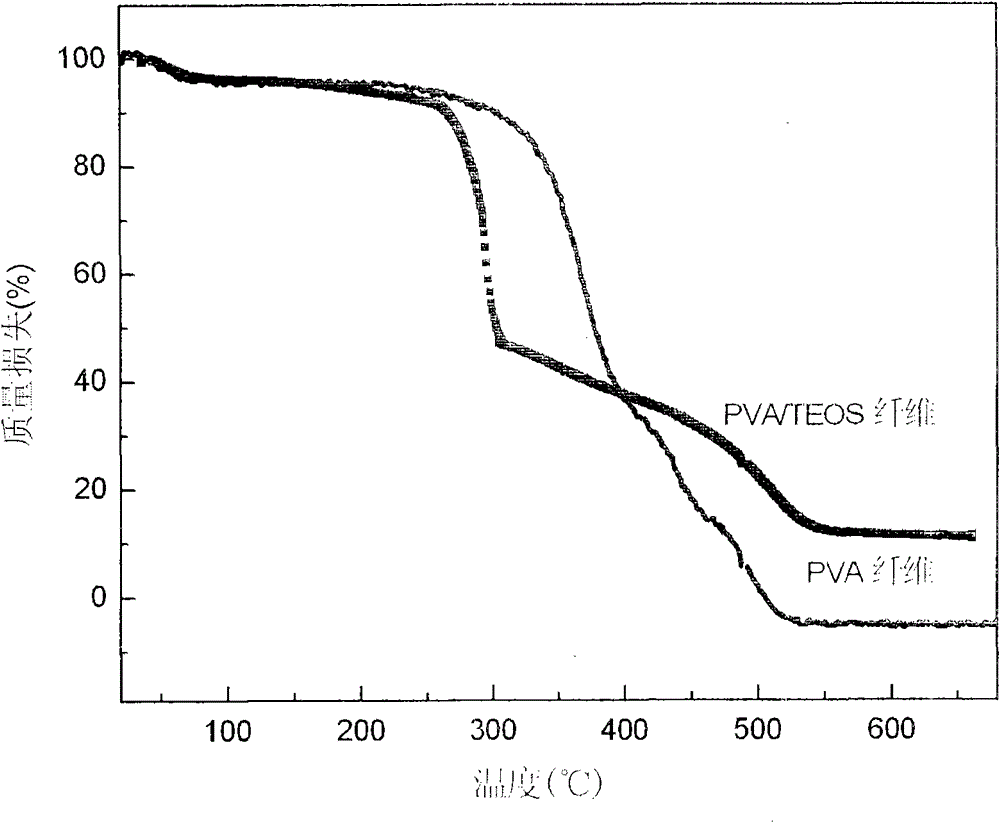

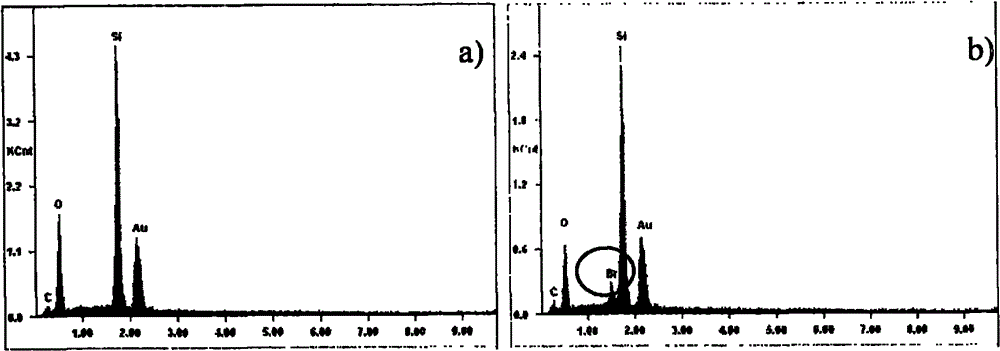

[0016] The hydrophobic silica nanofiber membrane prepared in this embodiment also has a large number of nanopores between the fibers, and there are a large number of in-situ hydrophobic functional groups on the surface of the hydrophobic silica nanofiber membrane. Completed at the same time as the preparation, these hydrophobic functional groups are combined with the matrix by chemical bonds. The binding force is strong, such as ...

specific Embodiment approach 2

[0017] Specific embodiment two: The difference between this embodiment and specific embodiment one is that the silane with functional groups described in step one is bromopropyl trichlorosilane, dodecyl trichlorosilane, methyl trichlorosilane, Octadecyltrichlorosilane, Monomethyltrichlorosilane, Vinyltrichlorosilane, Monophenyltrichlorosilane, Phenyltrichlorosilane, Chloropropyltrichlorosilane, Dimethyldichlorosilane, Methyl Phenyldichlorosilane, diphenyldichlorosilane, monomethyldichlorosilane, methylvinyldichlorosilane, monomethyldichlorohydrosilane, chloropropylmethyldichlorosilane, tert-butyldiphenyl Chlorosilane, tert-butyldimethylsilyl chloride, chloromethylsilane, chlorotrimethylsilane, bromotrimethylsilane, bromotrimethylsilane, iodotrimethylsilane, γ-aminopropyl Trimethoxysilane, γ-aminopropyltriethoxysilane, bis[3-(triethoxysilylpropyl)]amine, N-β-aminoethyl-γ-aminopropylmethyldimethoxy Silane, aminoethylaminoisobutylmethyldimethoxysilane, N-β-aminoethylγ-aminopropy...

specific Embodiment approach 3

[0019] Specific embodiment three: The difference between this embodiment and specific embodiment one or two is that the silane with functional groups described in step one can also be perfluorooctylethyltrimethoxysilane, trifluoropropyltrimethoxy Vinylsilane, Vinyltrimethoxysilane, Vinyltris(β-methoxyethoxy)silane, Vinylmethyldimethoxysilane, Vinylmethyldiethoxysilane, Vinyltriethoxysilane γ-methacryloxypropyltrimethoxysilane, γ-methacryloxypropylmethyldimethoxysilane, γ-methacryloxypropyltriethoxy Silane, 2-(3,4-epoxycyclohexyl)ethyltrimethoxysilane, 2-(3,4-epoxycyclohexyl)ethyltriethoxysilane, γ-glycidyl etheroxypropyl Trimethoxysilane, γ-glycidyloxypropylmethyldimethoxysilane, γ-glycidyloxypropylmethyldiethoxysilane, γ-glycidyloxypropylmethyl triethyl Oxysilane, γ-Chloropropyltrimethoxysilane, γ-Chloropropyltriethoxysilane, γ-Chloropropylmethyldimethoxysilane, γ-Chloropropylmethyldiethoxysilane , Methyltrimethoxysilane, Methyltriethoxysilane, Methyltriacetoxysilane, Methy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com