Method for preparing novel agricultural water-retaining agent and water-retaining agent

A technology of agricultural water-retaining agent and aqueous solution, which is applied in chemical instruments and methods, applications, agriculture, etc., can solve the problems of water retention not suitable for saline-alkali land, waste of resources, loss of water retention effect, etc., and achieve the effect of ensuring the growth of plants without lack of water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

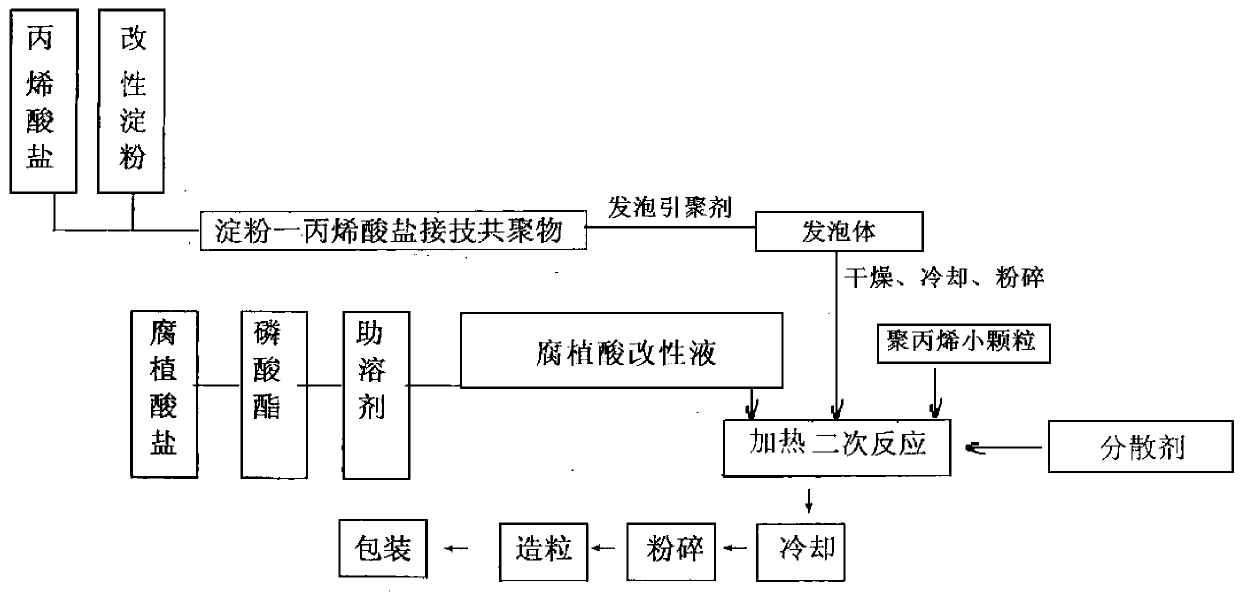

Embodiment 1

[0026] Add 1.2kg of modified starch to prepare 2kg of sodium acrylate aqueous solution, form starch-sodium acrylate graft copolymer after reaction, then add foaming polymerization initiator and directly polymerize into foam in tunnel cellar, after drying and cooling, powder pure spare. Sodium humate is prepared by sodium salt and nitrated humic acid, then modified by esterification with polyhydroxy phosphate, and then added with co-solvent to prepare a reactive black glue. Add the starch-acrylate graft copolymer produced in the above steps to polypropylene small particles and the active black glue solution prepared in the above steps, mix evenly under the action of the dispersant, react after heating to form a resin, and finally cool down, Powder and granulate to get the finished product. Among them, the added humate accounted for 20% of the total mass ratio, the added amount of the dispersant accounted for 6% of the total mass ratio, and the small polypropylene particles acc...

Embodiment 2

[0028] Prepare 5 kg of potassium acrylate aqueous solution and add 4 kg of modified starch to form a starch-potassium acrylate graft copolymer after reaction, then add a foaming polymerization initiator and directly polymerize into a foam in the tunnel cellar. After drying and cooling, it is pulverized spare. Sodium humate is prepared by potassium salt and nitrifying humic acid, then potassium humate is modified by esterification with polyhydroxy phosphate, and then a cosolvent is added to prepare a reactive black glue. Add the starch-potassium acrylate graft copolymer produced in the above steps to polyethylene small particles and the active black glue solution prepared in the above steps and mix evenly under the action of the dispersant, react after heating to form a resin, and finally cool down, Powder and granulate to get the finished product. Among them, the added humate accounted for 35% of the total mass ratio, the added amount of the dispersant accounted for 8% of the...

Embodiment 3

[0030] Prepare 5kg of ammonium acrylate aqueous solution and add 3kg of modified starch to form a starch-ammonium acrylate graft copolymer after reaction, then add a foaming polymerization initiator and directly polymerize into a foam in the tunnel cellar, dry and cool and then pulverize spare. Ammonium humate is prepared by using ammonium salt and nitrated humic acid, and then ammonium humate is modified by esterification with polyhydroxy phosphate, and then a cosolvent is added to prepare a reactive black glue. Add the starch-ammonium acrylate graft copolymer produced in the above steps to polyethylene small particles and the active black glue solution prepared in the above steps and mix evenly under the action of the dispersant, react after heating to form a resin, and finally cool down, Powder and granulate to get the finished product. Among them, the added humate accounted for 50% of the total mass ratio, the added amount of the dispersant accounted for 10% of the total ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com