A kind of tree peony organic granular slow-release fertilizer for oil and preparation method thereof

A technology of oil peony and organic granules, applied in the preparation of organic fertilizers, organic fertilizers, inorganic fertilizers, etc., can solve the problems of water retention, fertilizer retention effect and unsatisfactory disease prevention effect, so as to avoid fertilizer loss and reduce labor costs. Harm, increase the occurrence of oil peony root rot, reduce the effect of fertilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

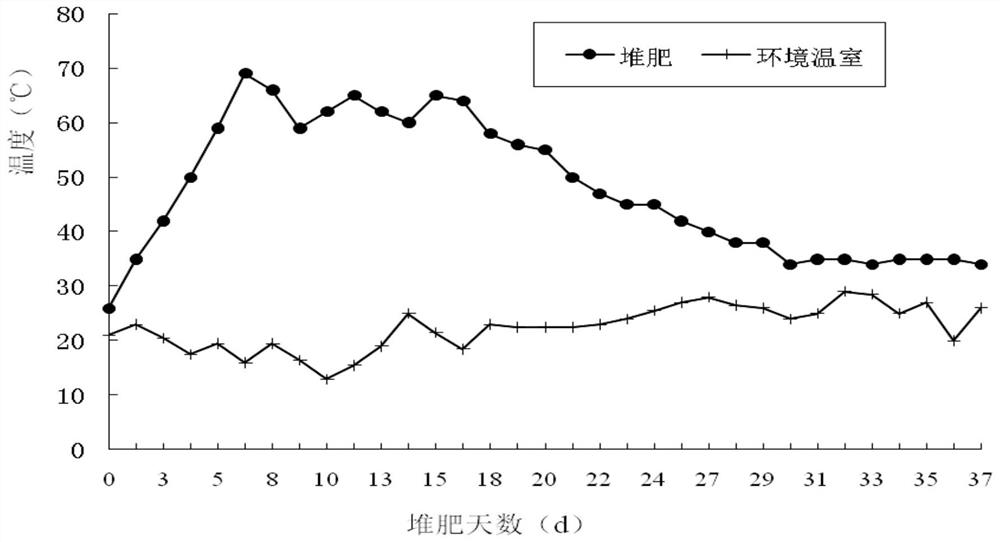

[0028] Example 1 The preparation of aerobic high-temperature composting of organic fertilizers and special fertilizers

[0029]Raw materials include peony waste for oil (pruned branches and leaves, peony seed pods, seed meal after peony oil extraction), crop straw, mushroom slag, fly ash, coal slime, etc. The tree peony pruning branch is used to crush the oil into 0.5-3cm (2cm in this embodiment), the peony seed pod is crushed into 0.5-2cm (diameter) particles, the peony seed meal is directly shaken by a shaker, and the crop straw is crushed to 2cm -5cm small pieces, the mushroom sticks are bagged and crushed when they are still fresh. Under the proportion of each material: 5 parts of peony pruned branches and leaves for oil, 5 parts of peony seed pods for oil, 5 parts of peony seed meal, 40 parts of mushroom dregs, 10 parts of crop straw (for example: corn, sorghum, wheat, rice can all be used) 15 parts of waste materials from corn starch processing plants, 7 parts of fly as...

Embodiment 2

[0032] Embodiment 2 The preparation of functional microbial bacterial agent coating layer

[0033] Bacillus subtilis ( Bacillus subtilis ), Paenibacillus polymyxa ( Paenibacillus polymyxa ) and Pseudomonas fluorescens ( Pseudomonas fluorescens ) with beef extract peptone medium, inoculated at 10% inoculum size, cultured on a shaker at 30°C, cultured for 5 days for Bacillus subtilis and Paenibacillus polymyxa, and for 3 days for Pseudomonas; Saccharomyces cerevisiae ( Saccharomyces cerevisiae ) was cultured with yeast extract powder glucose medium, the inoculum was inoculated at 10%, and cultured on a shaker at 28°C for 3 days; Penicillium oxalicum ( Penicillium oxalicum ) was cultured with potato glucose medium, the inoculum was inoculated at 10%, and cultured on a shaker at 26°C for 7 days. After the five kinds of bacteria are cultured, they are mixed according to equal volume ratios, and processed with a freeze dryer to obtain dry powder of mixed microbial bacteria...

Embodiment 3

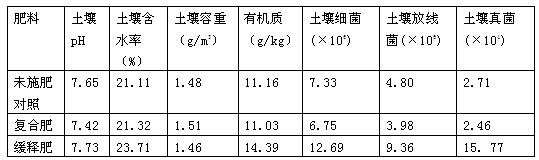

[0035] Example 3 Effect of oil-used tree peony microbial organic granule slow-release fertilizer

[0036] In order to compare the effects of slow-release fertilizers of peony microbial organic granules for oil, 4 groups of treatments were set up, treatment 1 was ordinary compound fertilizer (abbreviation: compound fertilizer), and treatment 2 was special organic fertilizer for oil peony without granulation (abbreviation: powder Fertilizer), treatment 3 is organic granular fertilizer for oil peony (abbreviation: granular fertilizer) that is granulated, and treatment 4 is granular fertilizer that is coated with microbial functional bacteria agent and coating layer (abbreviation: slow-release fertilizer). The amount of compound fertilizer is 150kg / mu according to the conventional field application rate, and the other three fertilizers are also applied in the conventional field organic fertilizer application rate of 1 ton / mu. The fertilization time is April, and it is applied all a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com