Method for machining adhesion belt and wafer

A technology of wafer processing and adhesive tape, which is applied in the field of adhesive tape, can solve problems such as device quality degradation and device function damage, and achieve the effect of eliminating quality reduction and suppressing static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

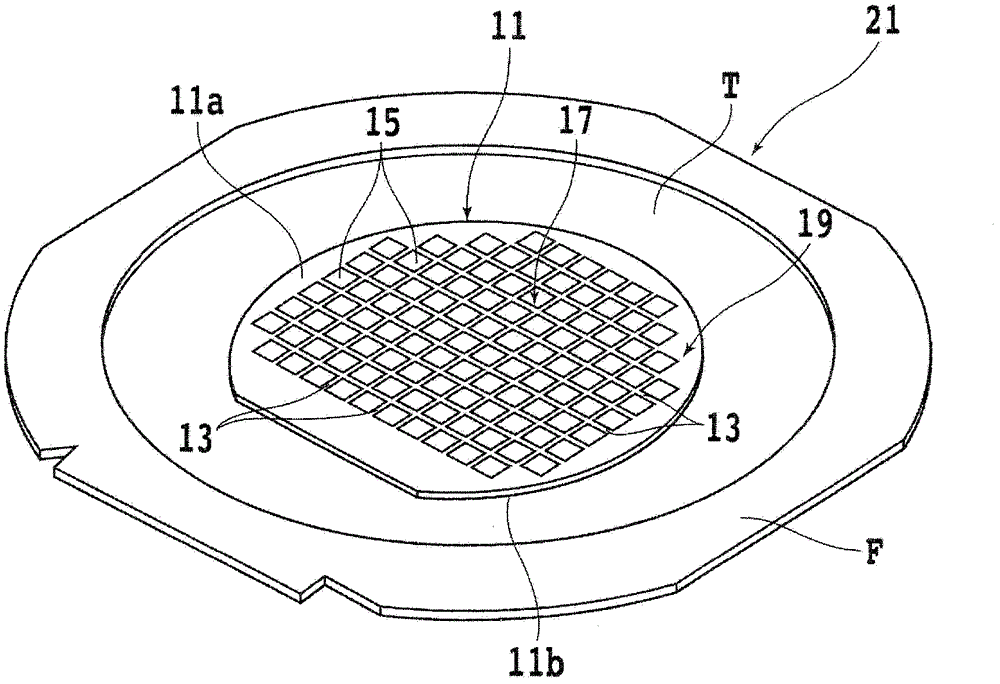

[0087] Such as figure 2 As shown, the silicon wafer 11 is supported by a ring frame F with a dicing tape T interposed therebetween, a laser beam is irradiated at intervals of 1.0 mm to form a degenerated layer inside the planned division line, and a plurality of squares of 1.0 mm×1.0 mm are divided, and then Dilated cutting zone T. The back surface of the dicing tape T was rubbed, and the charge amount of the wafer 11 was compared with the number of debris having a size of 5 μm or more scattered and attached to the surrounding area. The results shown in Table 1 were obtained.

[0088] 【Table 1】

[0089]

[0090] As can be seen from Table 1, the adhesive tape of the present invention having an antistatic layer on the back of the dicing tape T significantly reduced the amount of charge on the wafer compared to the conventional adhesive tape without an antistatic layer. Furthermore, the number of debris on the surface of the chip and the number of debris on the surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com