Treatment process for waste sodium citrate mother solution

A technology of sodium citrate and treatment process, applied in the direction of flocculation/sedimentation water/sewage treatment, animal feed, animal feed, etc., can solve the problems of increasing environmental protection load, product loss, difficult treatment, etc., to reduce environmental protection pressure and improve additional value, the effect of avoiding disturbance

Active Publication Date: 2012-10-24

RIZHAO JINHE BOYUAN BIOCHEM

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

During the production process, waste sodium citrate mother liquor will be continuously produced. In order to avoid the continuous decline in the quality of finished products, part of the waste sodium citrate mother liquor will be discharged. In this part of the waste sodium citrate mother liquor, except for the main component of citric acid In addition to sodium, it is also rich in protein colloids and a small amount of impurities such as cellulose, organic acids, sugars, pigments, minerals, etc., which either come from raw materials or accumulate during circulation. Difficult to deal with, most enterprises directly discharge into the environment, which not only causes product loss, but also increases the environmental load, therefore, it is urgent to find an effective way to deal with waste sodium citrate mother liquor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

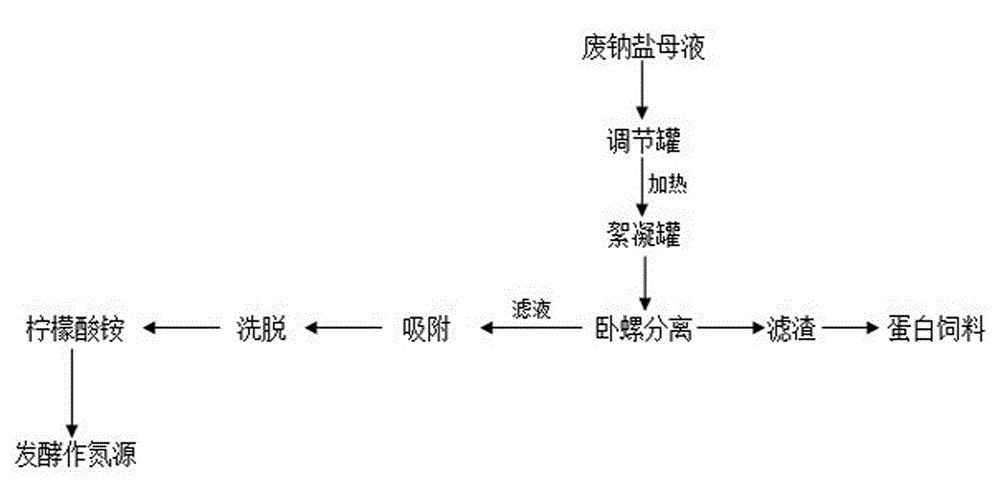

The invention relates to the field of biochemical engineering, and specially relates to a treatment process for a waste sodium citrate mother solution. The treatment process mainly comprises transforming the waste sodium citrate mother solution into ammonium citrate through processes of flocculation, centrifugal separation, adsorption, elution, and the like; and returning the obtained ammonium citrate to a fermentation process for recycling use as an organic nitrogen source. By adopting the treatment process, direct effluent of the waste sodium citrate mother solution can be prevented and pressure of environmental protection is relieved. The treatment process provides the nitrogen source for the fermentation process, turns the waste into wealth, and has considerable economic benefit and environment-friendly benefit.

Description

technical field [0001] The invention relates to the field of biochemical industry, in particular to a process for treating waste sodium citrate mother liquor. Background technique [0002] Sodium citrate is an organic acid salt widely used in food, beverage, chemical and pharmaceutical fields. At present, the production process adopted by most citric acid enterprises is the neutralization process, that is, the purified citric acid solution is directly mixed with sodium hydroxide reaction to produce sodium citrate. During the production process, waste sodium citrate mother liquor will be continuously produced. In order to avoid the continuous decline in the quality of finished products, part of the waste sodium citrate mother liquor will be discharged. In this part of the waste sodium citrate mother liquor, except for the main component of citric acid In addition to sodium, it is also rich in protein colloids and a small amount of impurities such as cellulose, organic acids...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C12P7/48C02F1/52A23K1/00

Inventor 寇光智高晓彤于海彬李昌涛刘剑雄周昊

Owner RIZHAO JINHE BOYUAN BIOCHEM

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com