Plate-shaped heat exchange element as well as hydrophilous heat exchange device and manufacturing method of plate-shaped heat exchange element

A heat exchange element, plate-shaped technology, applied in heat exchange equipment, laminated elements, fixed plate conduit components, etc., can solve the problems of limited heat exchange area, complicated manufacturing process, high operating cost, etc., and achieves easy installation and maintenance. Increase heat exchange area, anti-fouling, easy to clean and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

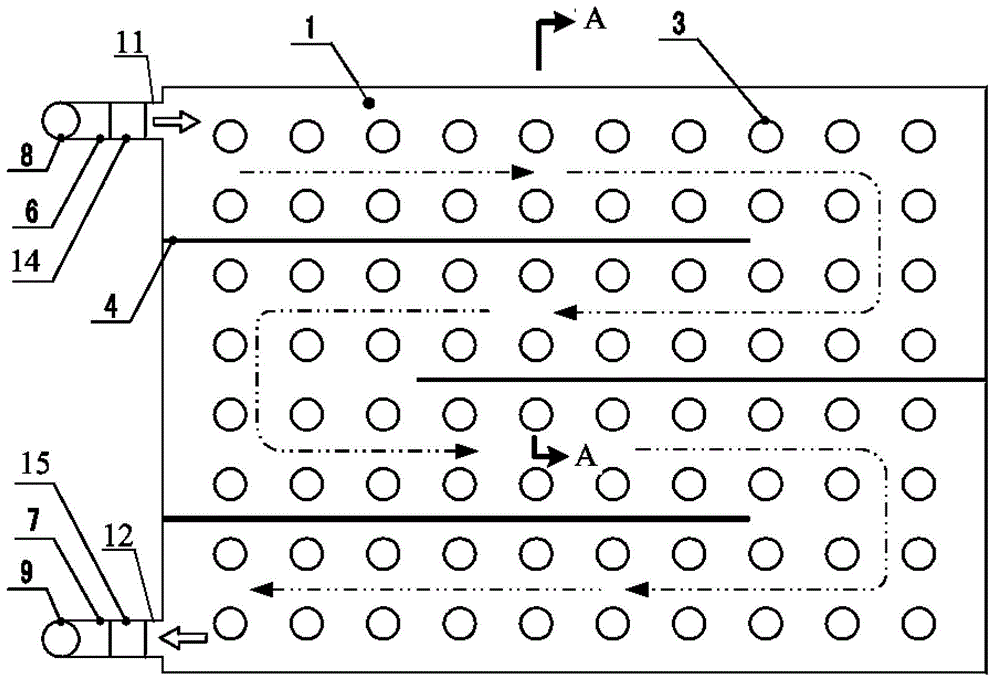

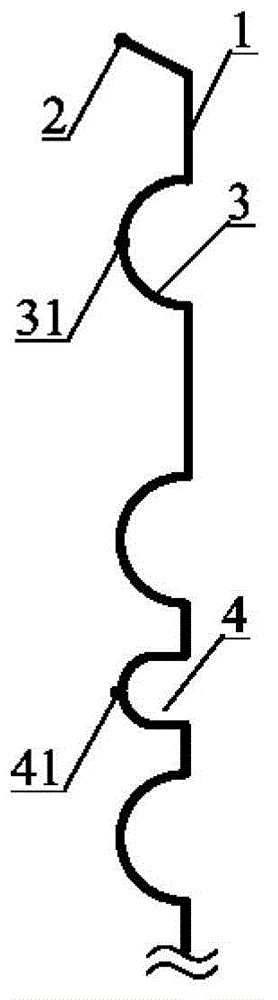

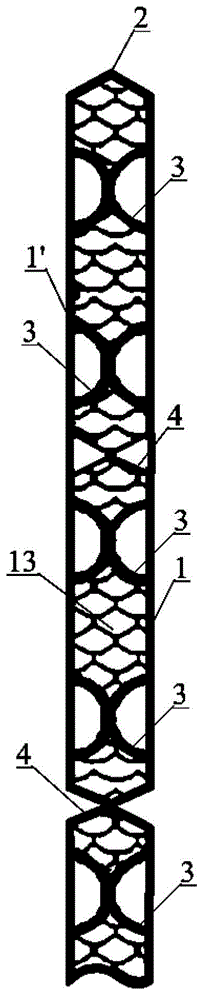

[0038] The structure of the plate heat exchange element 10 of the water medium heat exchange device used in the surface water source heat pump system of the present invention is as follows: figure 1As shown, it includes a water inlet 11, a water outlet 12 and two heat exchange plates 1 and 1' welded on the periphery. Between the two heat exchange plates 1 and 1', there is a water inlet 11 and a water outlet. 12 connected circulation chambers, the heat exchange plates 1 and 1' are provided with a stamped and stretched diversion belt structure 4 and an enhanced heat exchange structure 3; the diversion belt structure 4 has a U-shaped cross-sectional shape on the heat exchange plate Or V-shaped strip-shaped protrusions. exist figure 1 in, in figure 2 The cross-sectional shape of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com