Device and method for evaluating foaming performances of foaming agent under conditions of high temperature and high pressure

A high-temperature, high-pressure, evaluation device technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem that parameters such as the foaming ability and stability of the foaming agent cannot be obtained, the evaluation method cannot meet the requirements, and the guiding significance of foam application is not enough. major issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

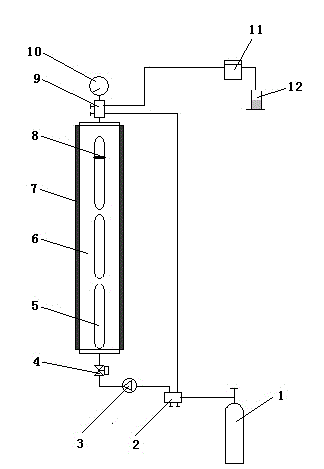

[0018] Embodiment 1: as figure 1 As shown, take 100mL of the existing commercially available sodium lauryl sulfate foaming agent solution with a mass concentration of 0.5% and add it to the high-temperature and high-pressure container 6, control the temperature to the experimental temperature of 90°C through the heating jacket 7, and control the back pressure valve 11 to The test pressure is 8MPa, open the valve connected to the high-pressure gas cylinder 1 in the double valve 7 and double valve 2 at the top outlet of the container, pressurize the high-temperature and high-pressure container 6 to the test pressure of 8MPa, and close the outlet double valve 7 and the double valve 2 connected with the high-pressure gas cylinder. The valve connected to the bottle 1; open the valve connected to the back pressure valve 11 in the outlet double valve 7, set the gas mass flow meter 3 to the design flow rate of 200mL / s, then open the air inlet valve 4 at the bottom of the container to f...

Embodiment 2

[0019] Embodiment 2: as figure 1 As shown, take 100mL of the existing commercially available sodium lauryl sulfate foaming agent solution with a mass concentration of 0.5% and add it to the high-temperature and high-pressure container 6, control the temperature to the experimental temperature of 70°C through the heating jacket 7, and control the back pressure valve 11 to The test pressure is 6MPa, open the valve connected to the high-pressure gas cylinder 1 in the double valve 7 and double valve 2 at the top outlet of the container, pressurize the high-temperature and high-pressure container 6 to the test pressure of 6MPa, and close the outlet double valve 7 and the double valve 2 connected with the high-pressure gas cylinder. The valve connected to the bottle 1; open the valve connected to the back pressure valve 11 in the outlet double valve 7, set the gas mass flow meter 3 to the design flow rate of 300mL / s, then open the air inlet valve 4 at the bottom of the container to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com