Three-rotational-freedom series-parallel driving mechanism

A driving mechanism and a degree of freedom technology, which is applied in the field of three-rotation degree of freedom hybrid drive mechanism, can solve the problems of increasing the quality of the motion branch chain, unfavorable high-speed motion of the mechanism, etc., and achieves high bearing capacity, simple structure, and reduced production and maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The three-rotation-degree-of-freedom hybrid driving mechanism provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

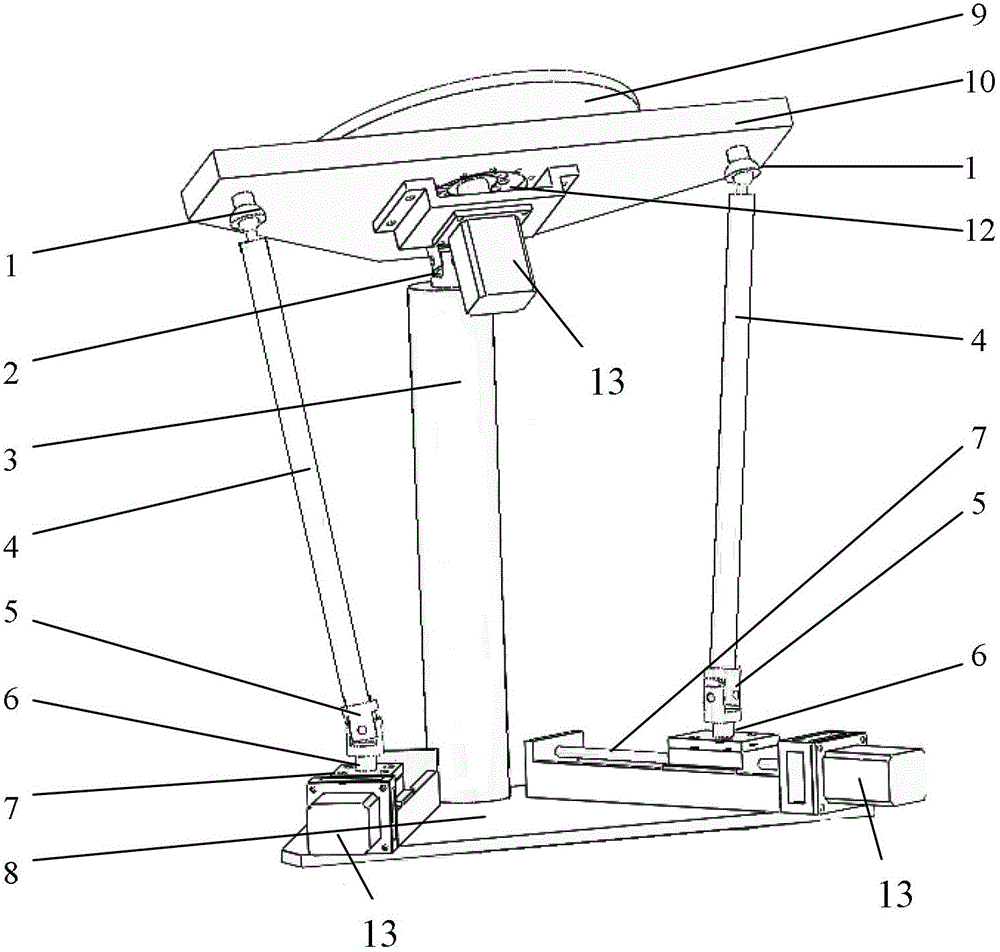

[0012] Such as figure 1 As shown, the three rotation degrees of freedom hybrid drive mechanism provided by the present invention is composed of a two rotation degrees of freedom parallel mechanism and a 360° rotation degree of freedom mechanism connected in series; wherein the two rotation degrees of freedom parallel mechanism includes a static platform 8, located on the static platform The dynamic platform 10 above the 8 and a constraint branch chain and two drive branch chains connected between the static platform 8 and the dynamic platform 10; the constraint branch chain is composed of the static platform connection support 3 and the Hooke hinge 2 Wherein the static platform connecting support 3 is vertically arranged, the lower end is fixed on the surface middle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com