Non-aqueous cell having a mixture of fluorinated carbon cathode materials

A cathode material, chemical battery technology, applied to battery electrodes, circuits, electrical components, etc., can solve problems such as low working voltage power capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

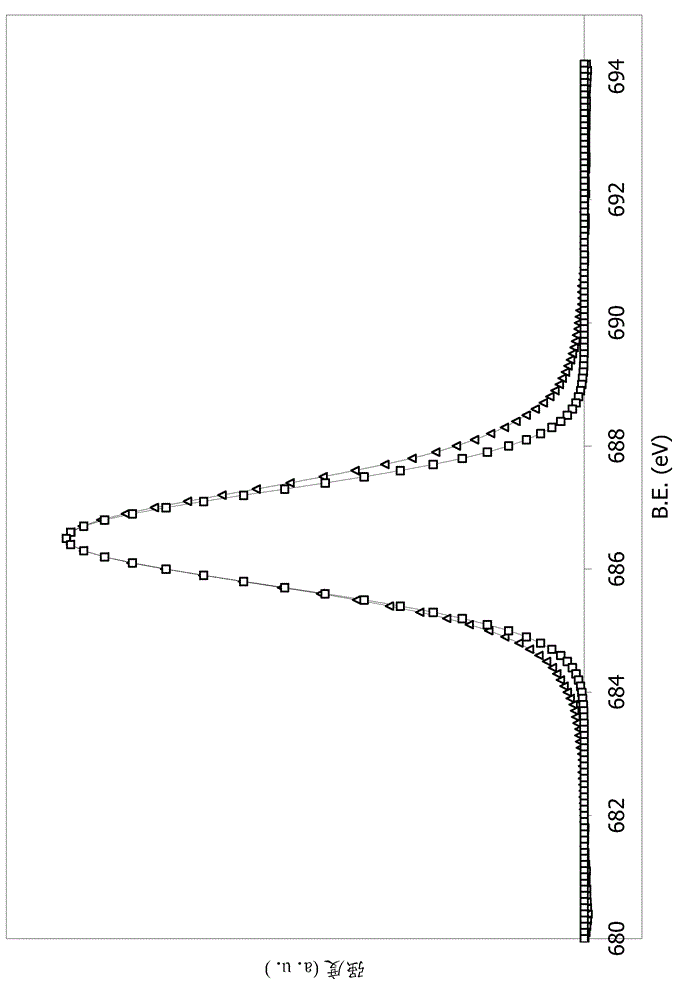

[0087] Example 1: Fluorinated carbons (CF 1 ) and fluorocarbons (CF 1 ) physical and chemical characterization

[0088] Determination of fluorinated carbons (i.e., CF x , which can be used as CF 1 Commercially available, but as given in Table 2 below, it was determined analytically to be closer to CF 0.9 ) and fluorocarbons derived from pitch (ie, CF z , as given in Table 2 below, which in this case is CF 1 ) X-ray diffraction pattern to characterize the properties and physical structure of the CF material ( image 3 ). image 3 This shows that there is very little difference in the XRD signals between these two CF materials.

[0089] The crystal size of the material is calculated by the following formula:

[0090]

[0091] Among them, L c is the crystal size, K is the instrument constant (usually 1), λ is the wavelength of X-rays (1.54 Å), L is the full width at half maximum (FWHM), and θ is the diffraction angle. The crystal size (L c ) is 2.99 nm, wh...

Embodiment 2

[0102] Example 2: Determination of the discharge curve (50J pulse) of a prior art battery and a battery containing a hybrid cathode according to the invention

[0103] Two 2.5Ah Li / CF cells were constructed in sealed aluminum bags. One cell contains a hybrid cathode containing a mixture of three CF materials: 40% by weight of the formula CF 1 of fluorinated carbons derived from coke, 10% by weight of formula CF 0.6 of fluorocarbons derived from coke and 50% by weight of formula CF 1 of fluorocarbons derived from bitumen. The second battery is a prior art Li / CF battery. The hybrid cathode also contains carbon as conductive filler (6% by weight of KS-4 graphite for the cathode and 4% by weight of Super P carbon black for the cathode, both from TIMCAL) and Polyvinylidene fluoride (PVDF). The materials were mixed and spread on a carbon coated aluminum current collector. About five pairs of cathode separators and anodes are stacked and formed into the bag cell.

[0104] Th...

Embodiment 3

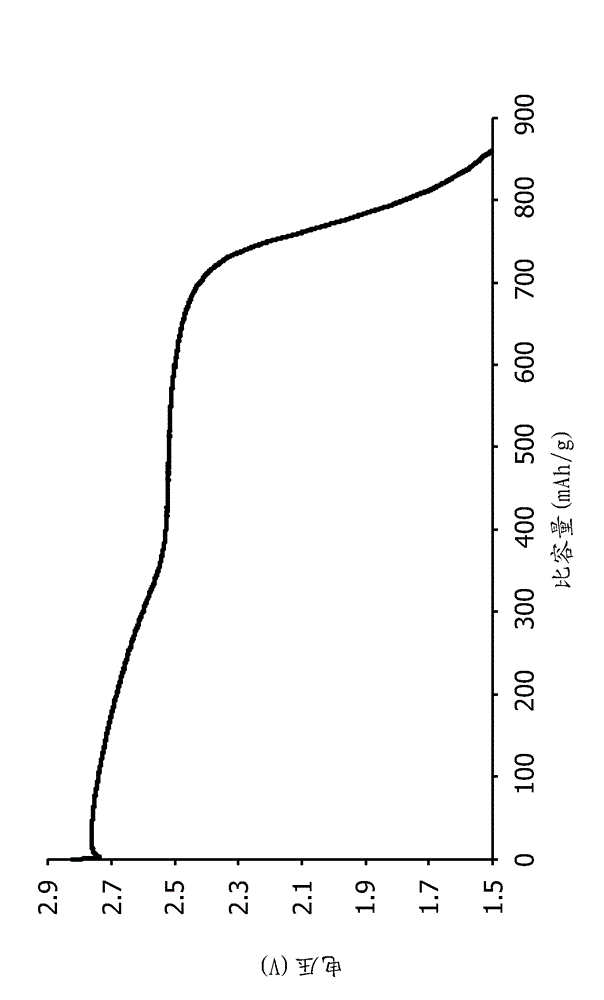

[0107] Example 3: Determination of the discharge curve (50J pulse) of a battery containing a carbon fluoride cathode derived from pitch

[0108] For the purpose of comparison with Example 2, a fluorinated carbon cathode (CF) derived from pitch was prepared according to the method of Example 2 1 or P5000) batteries. The battery was subjected to the same 50J pulse process as in Example 2 ( Figure 13 ). Such as Figure 13 As shown, the minimum voltage of the pulse at the beginning of life is about 2.5V high. Figure 13 Also shown is the curve for a battery containing the hybrid battery of Example 2, which has a minimum voltage of 2.4 V high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com