Axial and radial reactor of fixed bed with tube bank wall type internal and external barrels

A technology of inner and outer cylinders and fixed bed, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low strength of inner and outer cylinders, high processing cost, complicated manufacturing, etc., and achieve simple structure, small resistance reduction, and wide opening. The effect of porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

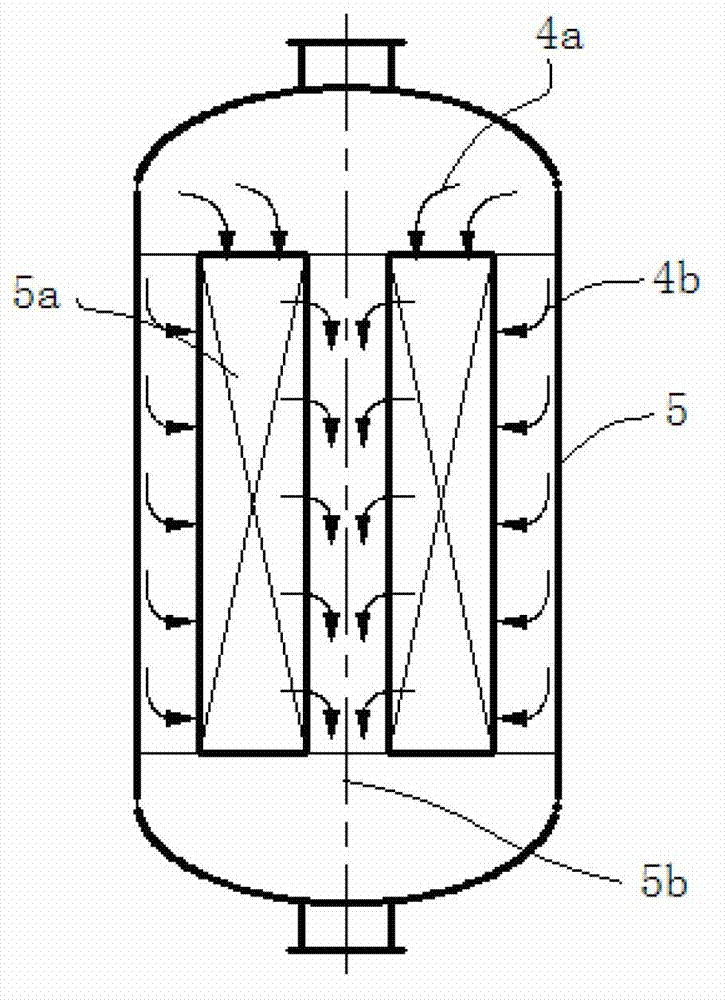

[0032] see Figure 4 , the fixed-bed axial radial reactor with calandria wall-type inner and outer cylinders shown in the figure includes a pressure-bearing shell 100 and a catalyst cylinder part installed in the pressure-bearing shell 100 .

[0033] The pressure-bearing shell 100 includes an upper head 110, a lower head 120, a cylinder body 130, and a support 140; Comprehensive selection of medium characteristics. When the fixed-bed axial-radial reactor with pipe-walled inner and outer cylinders is applied to the coal chemical industry sulfur resistance conversion process, the inner walls of the upper head 110, the lower head 120, and the cylinder body 130 are lined with stainless steel linings.

[0034] The upper head 110 is welded to the top of the cylinder 130, and the upper head 110 is provided with a manhole 111 and a thermocouple inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com