Lining sliding plate of warp knitting machine

The technology of warp knitting machine and sliding plate is applied in the field of lining plate, which can solve the problems of increasing the production cost of weft laying mechanism, high production cost of lining plate, expensive PTFE plate, etc., and achieves simple and easy assembly and disassembly, long service life, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

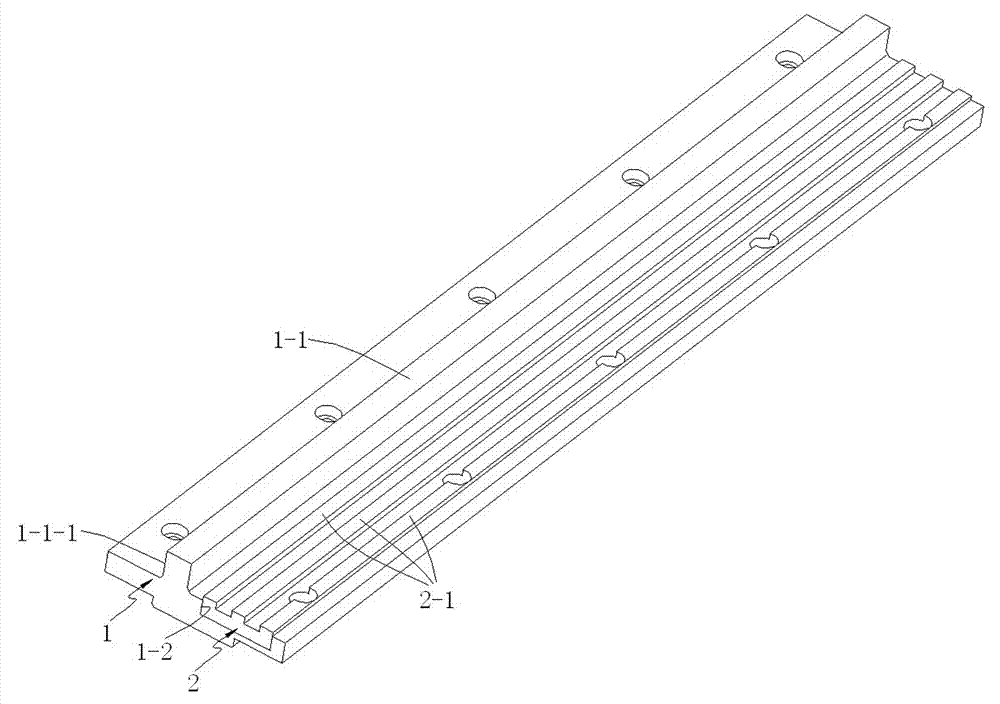

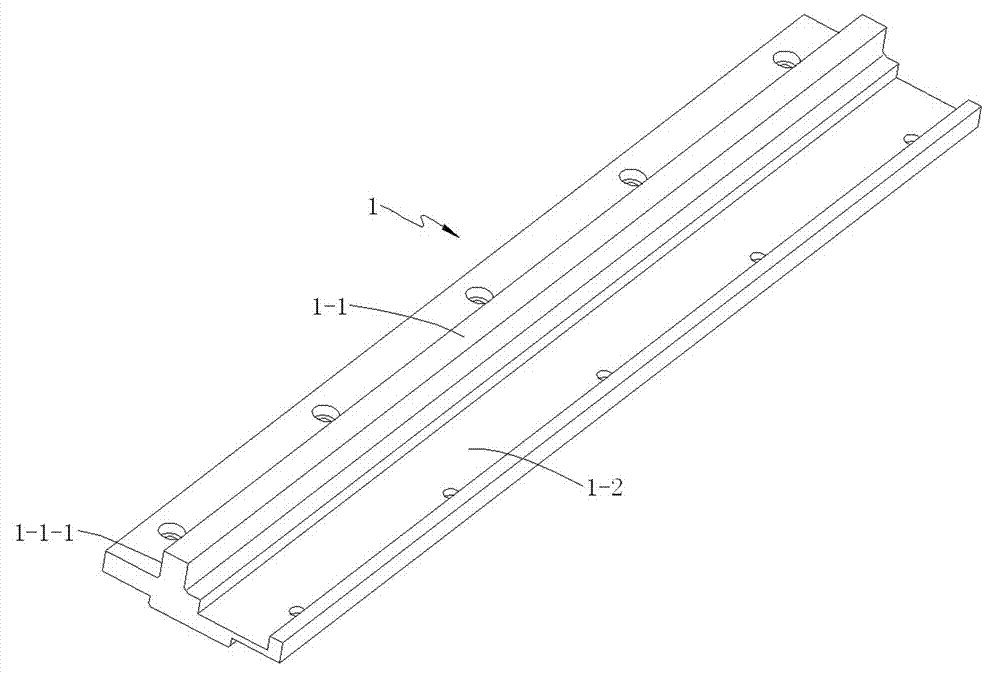

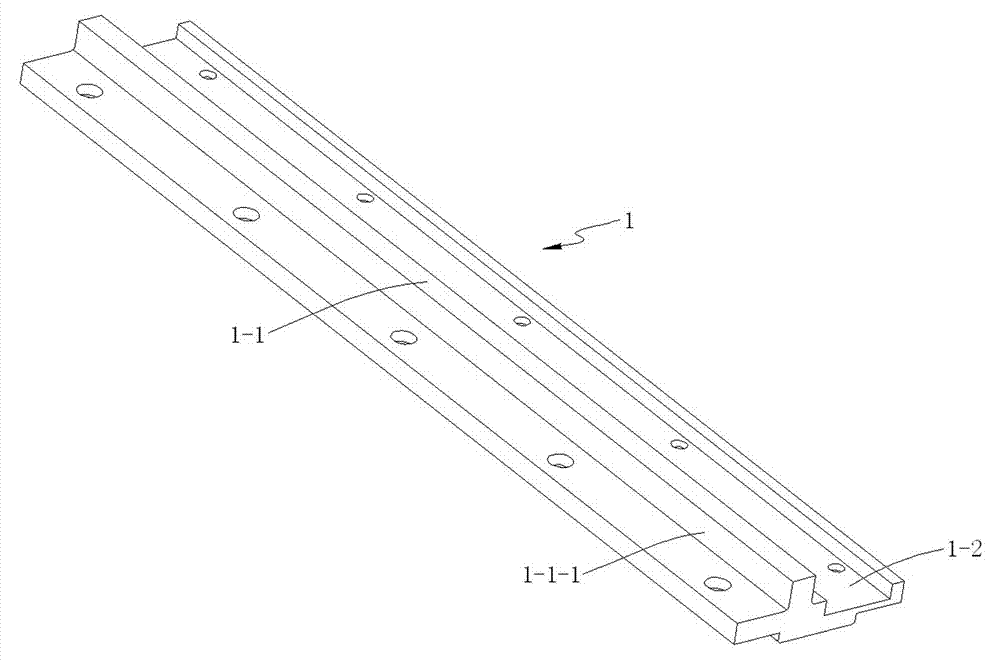

[0022] see Figure 1 to Figure 5 A kind of lining slide plate of warp knitting machine shown, when laying weft, the weft inserting chain of warp knitting machine slides on this lining slide plate, and this lining slide plate is made of base plate 1 made of metal material and is made of non-metal wear-resistant material. formed liner 2; on the upper surface of the base plate 1 there is a strip-shaped boss 1-1 extending along its length, the liner 2 is detachably mounted on the base plate 1 On the end face, the backing plate 2 is slidably connected with the weft inserting chain 3 . like figure 1 , 2 , 3 and 5, the cross-section of the strip-shaped boss 1-1 is preferably rectangular, and of course it can also be in other shapes, which are not shown in the figure.

[0023] In order to facilitate the installation and positioning of the liner 2, the present invention sets a groove 1-2 on the upper surface of the base plate 1, the liner 2 is embedded in the groove 1-2, and the lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com