High-pressure liquid air energy storage/release system

A technology of liquid air and high-pressure air, applied in the direction of machines/engines, mechanical equipment, mechanisms that generate mechanical power, etc., can solve problems such as high energy, consumption, and reduced operating efficiency of energy storage systems, and achieve high energy density and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

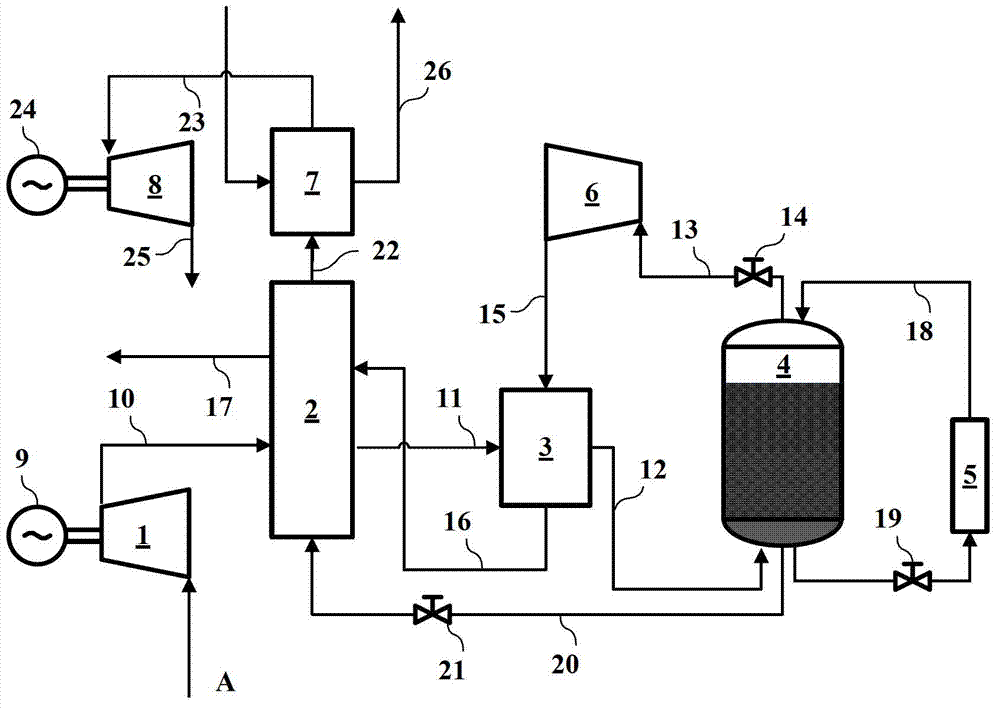

[0041] Such as figure 1 Shown is Embodiment 1 of the high-pressure liquid air energy storage / energy release system of the present invention. Among them, compressor unit 1, cold accumulator 2, low-temperature heat exchanger 3, high-pressure liquid air storage tank 4, self-supercharger 5, low-temperature expander 6, heat storage / heat exchanger 7, main expansion unit 8, generator 24 , drive motor 9, valves 14, 19, 21, pipelines 10, 11, 12, 13, 15, 16, 17, 18, 20, 22, 23, 25, 26, inlet air A.

[0042] The drive motor 9 is fixedly connected to the common transmission shaft of the compressor unit 1 , and the generator 24 is fixedly connected to the common transmission shaft of the expander 8 . The inlet of the compressor unit 1 is connected to the air A, and communicates with the regenerator 2 through the pipeline 10 . The cold accumulator 2, the low-temperature heat exchanger 3, and the high-pressure low-temperature liquid storage tank 4 are sequentially connected through pipelin...

Embodiment 2

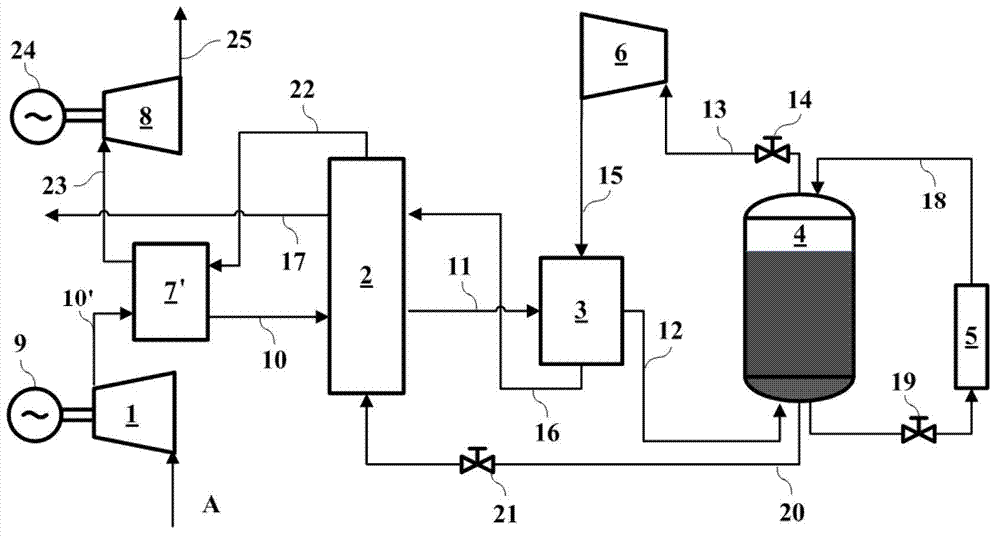

[0047] figure 2 It is Embodiment 2 of the high-pressure liquid air energy storage / energy release system that stores and releases compression heat of the present invention. Its main structure is the same as that of Embodiment 1. The high-pressure air generated by compressor unit 1 is cooled by heat storage / heat exchanger 7' After entering the cold accumulator 2, the heat accumulator / heat exchanger 7' mainly stores and releases the compression heat of the compressed air.

[0048] When storing energy, the high-pressure air at the outlet of the compressor unit 1 first enters the heat storage / heat exchanger 7', and the heat generated by the compressed air is absorbed by the heat storage material, while the temperature of the high-pressure air drops to normal temperature. The normal-temperature high-pressure air exiting the heat storage / heat exchanger 7 ′ enters the cold storage 2 sequentially, and the low-temperature heat exchanger 3 is liquefied and stored in the high-pressure li...

Embodiment 3

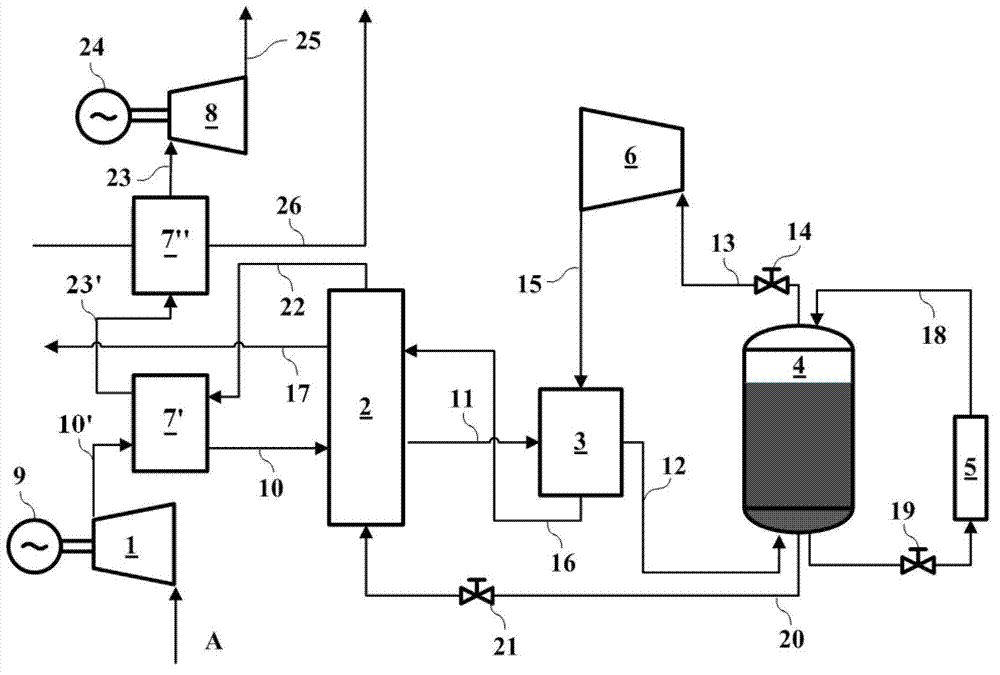

[0050] image 3 It is the embodiment 3 of the combination of the high-pressure liquid air energy storage system of the present invention and solar thermal power generation or industrial waste heat utilization. Its main structure is the same as that of embodiment 2, and the connection with solar collectors or industrial waste heat / waste heat pipelines is added. part. The high-temperature fluid from the solar collector or industrial waste heat / waste heat enters the high-temperature heat storage / heat exchanger 7" through the pipeline 26, and the high-temperature fluid releases heat and cools down in the high-temperature heat storage / heat exchanger 7". The main high-pressure air coming out of the heat storage / heat exchanger 7' is heated to a high temperature in the high-temperature heat storage / heat exchanger 7", and then enters the main expansion unit 8 through the pipeline 23 to expand and perform work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com