Motor vehicle components and methods of making the same

A technology for motor vehicles and components, applied in mechanical equipment, engine components, machines/engines, etc., to achieve the effects of reducing vibration, increasing stiffness, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

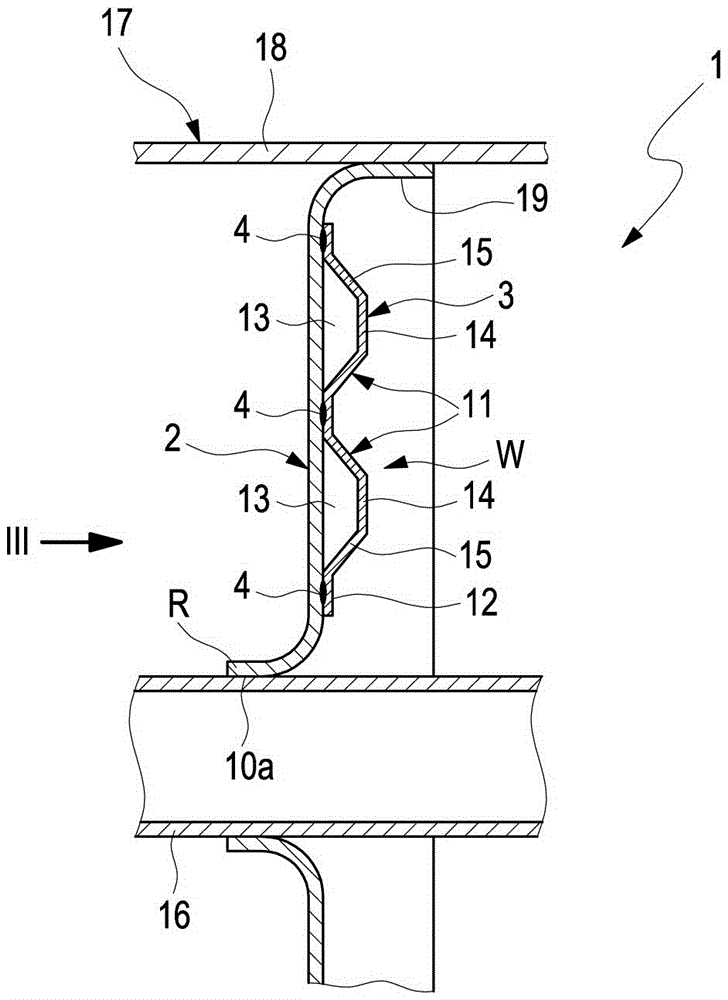

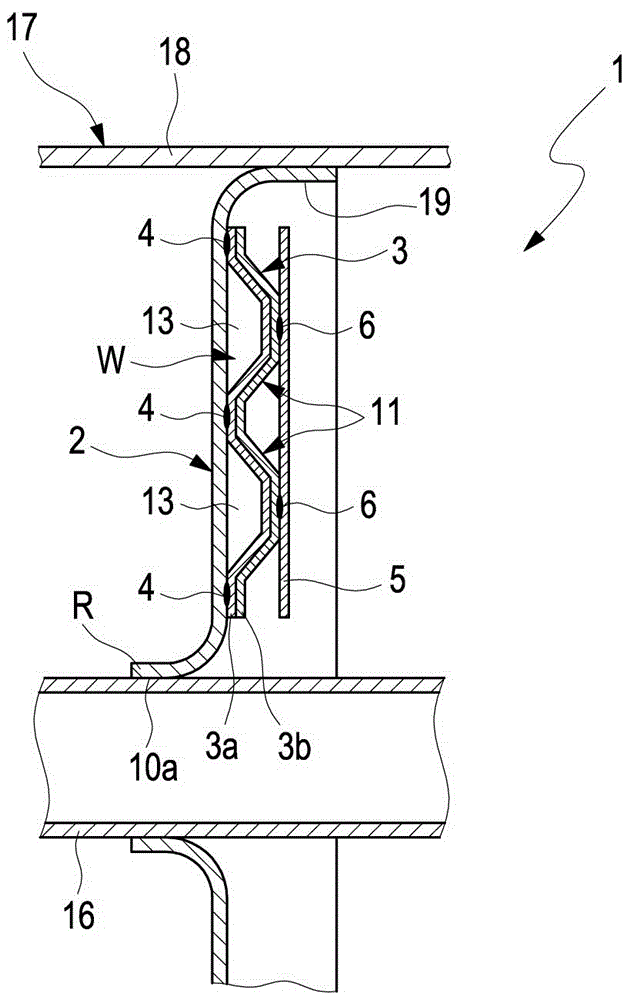

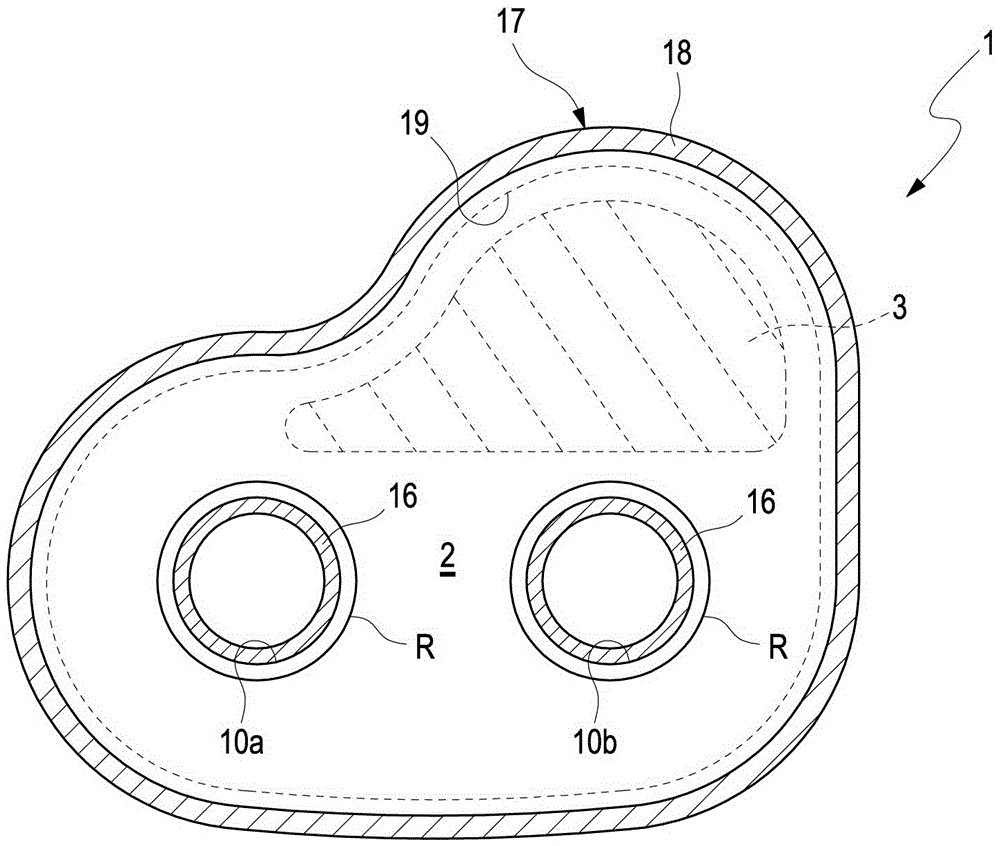

[0030] according to figure 1 , reference numeral 1 describes an assembly according to the invention, expressed here in the form of a silencer. The assembly 1 comprises a carrier 2 which can form part of a housing 17 of the assembly 1 or can be arranged inside the housing 17 of the assembly 1 . In the lower area, according to figure 1 The carrier 2 has a substantially circular opening 10a with a protruding edge R. The exhaust pipe 16 passes through this opening 10a. Exhaust duct 16 is capable of forming a sliding fit with edge R. As shown in FIG. Alternatively, the exhaust pipe 16 can be fastened to the edge R, for example by means of a gas-tight weld. In the upper region above the edge R, the carrier 2 extends substantially vertically upwards in the plate surface. On the side of the carrier 2 facing away from the edge R, for example towards the inside of the module 1, the carrier 2 comprises a flat, preferably flat area in the upper region, wherein the plate 3 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com