Small hard seed stepless precision drill

A seed drill and hard technology, applied in the directions of sowing seeders, planter parts, fertilizers and sowing equipment, etc., can solve the problems of cluttered plant growth, low seed germination rate, and difficulty in controlling the sowing rate, and achieve a large adjustment range and improve The effect of germination rate and soil layer is not disordered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

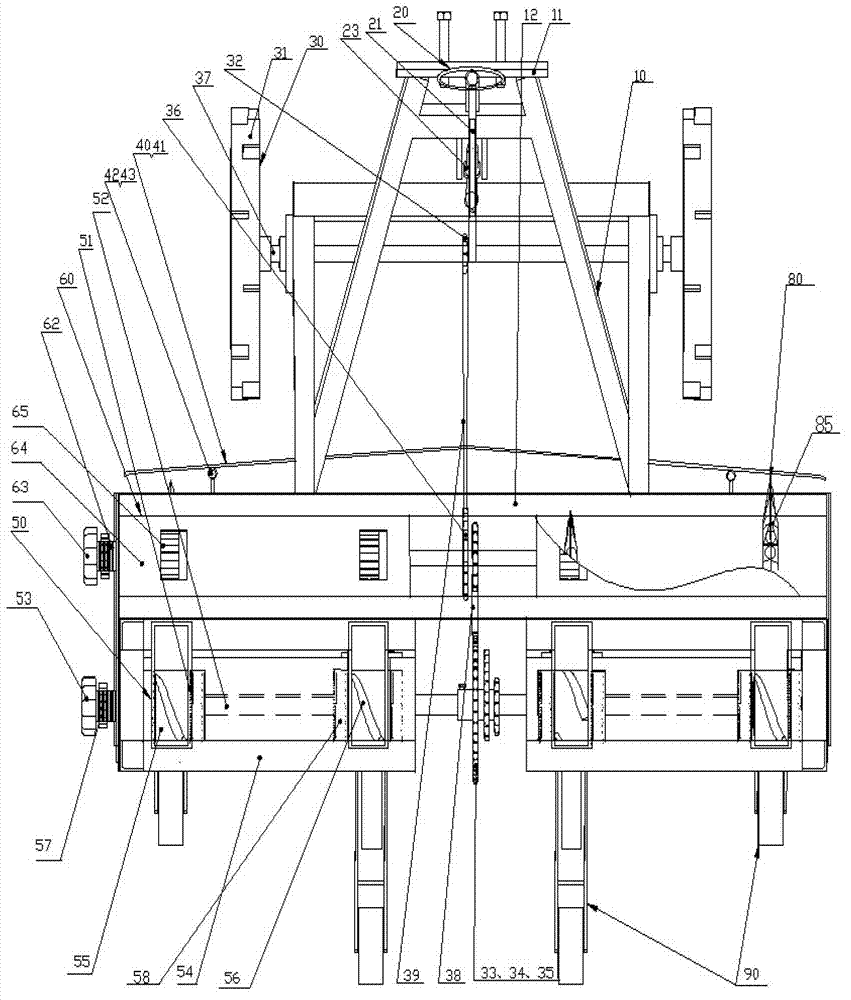

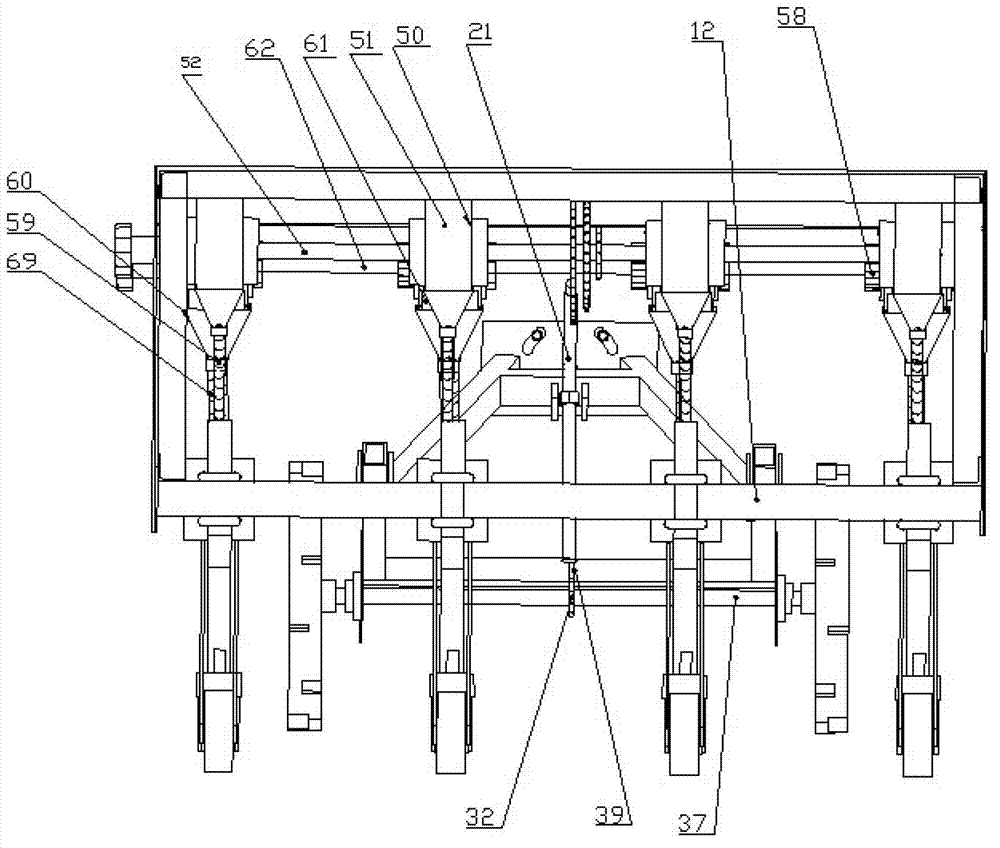

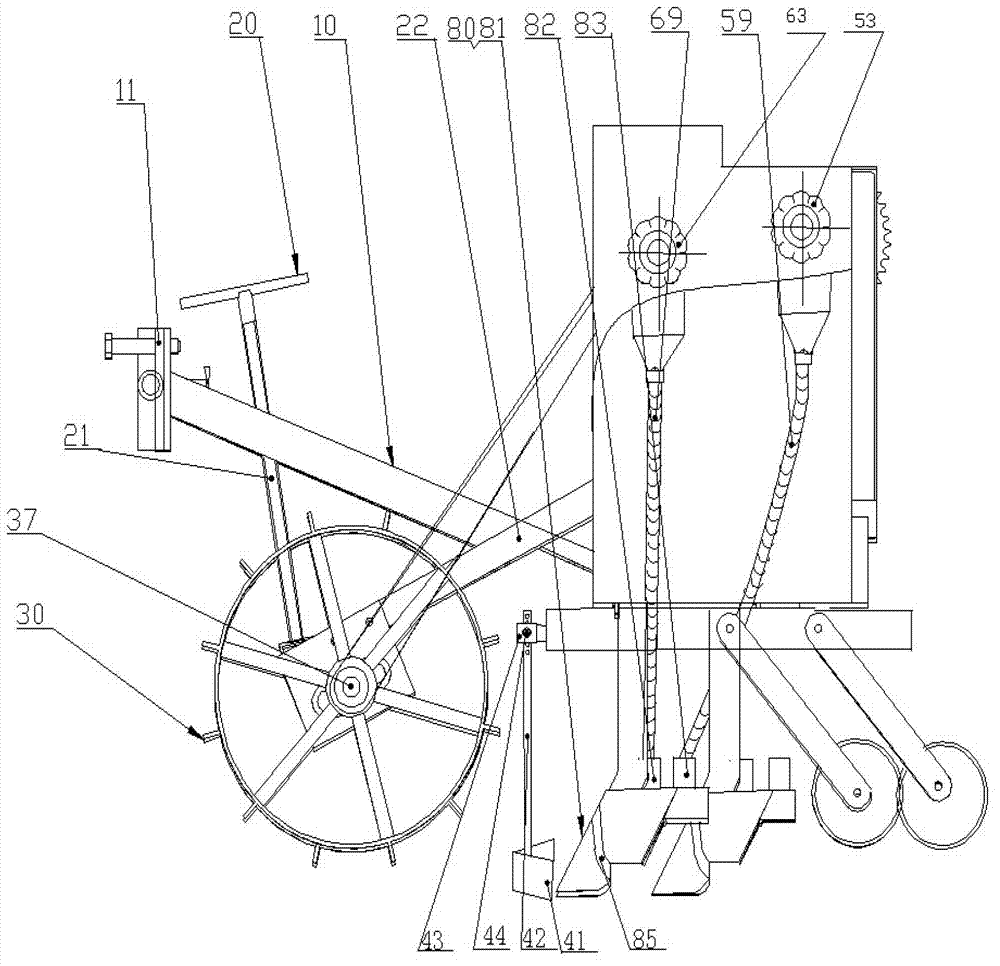

[0034] Example 1, see Figure 1-6, a stepless precision seed drill for small hard seeds, including a frame 10 made up of a suspension device 11 and a load-bearing platform 12, a sowing depth adjustment device 20 and a walking ground wheel transmission system 30 are arranged below the suspension device 11. A seeding device 50 and a fertilizer discharge device 60 are provided above the load-bearing platform 12, and a ditch opener 80 and a soil covering suppression device 90 are provided below the load-bearing platform 12. The seeding wheel 55 of the seeding device 50 is provided with a spiral gradient groove 56; the ground wheel shaft 37 of the walking ground wheel transmission system 30 is provided with a single sprocket 32, the transmission chain 39 is connected to the double sprocket 36 provided on the fertilizer discharge shaft 62 through the single sprocket 32, and the second transmission chain 38 connects the triple sprocket 33,34,35 that is provided with on the seeding sh...

Embodiment 2

[0042] Embodiment 2 is the same as Embodiment 1, but the difference is that the triple sprockets 33, 34, and 35 of the transmission system 30 have teeth numbers of 40-45, 30-40, and 15-20 respectively, and the corresponding rotational speeds are 3.0-4.5r / min, 4.5~6.0r / min, 8~15r / min, by changing the number of triple sprocket teeth and fine-tuning the effective working length of the spiral gradient groove 56, the precision sowing of economic crops such as rapeseed is 0.5~0.6 kg / mu, 0.6 ~0.8 kg / mu, 0.8~1.0 kg / mu agronomic demand.

Embodiment 3

[0043] Embodiment 3 is the same as Embodiment 1, but the difference is that the triple sprockets 33, 34, and 35 of the transmission system 30 have teeth numbers of 32 to 42, 22 to 30, and 10 to 15 respectively, and the corresponding speeds are 2.8 to 3.8 r / min, 4.0~5.0r / min, 9~12r / min, by changing the number of triple sprocket teeth and fine-tuning the effective working length of the spiral gradient groove 56, the precision sowing of economic crops such as flax is 5.0~8.0 kg / mu, 8.0 ~10.0 kg / mu, 10~12 kg / mu agronomic demand.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com