Vacuum box for applying load in vacuum to manufacture vacuum thermal insulation plate

A technology of vacuum insulation panels and loading, which is applied to flat products, household appliances, other household appliances, etc., can solve problems such as increased operating costs, collapse of vacuum insulation panels, increase in thermal conductivity, etc., to shorten the vacuuming time, the overall The effect of good flatness and reduced thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

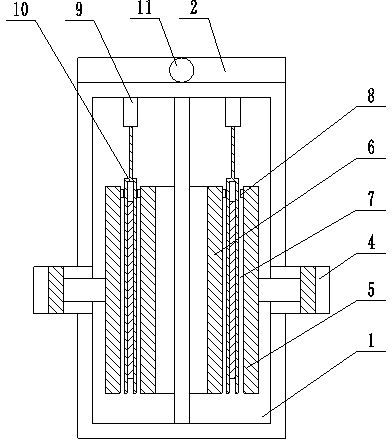

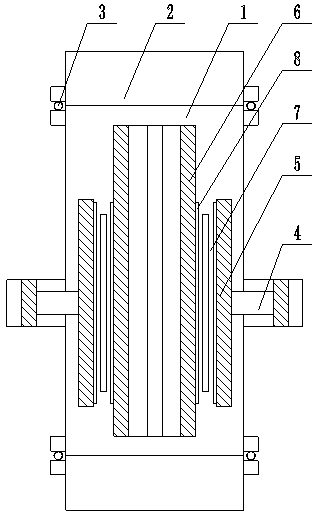

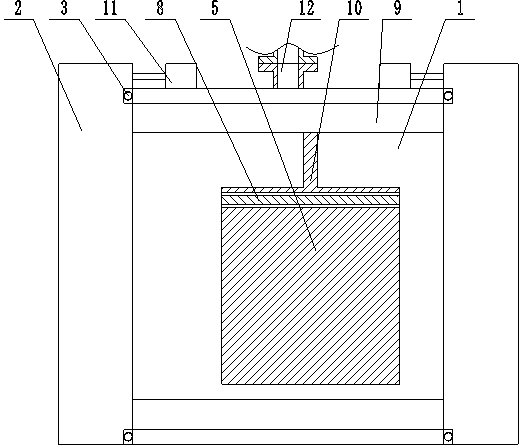

[0023] Such as figure 1 , figure 2 , image 3 As shown, the present invention applies load in vacuum to manufacture the vacuum box of the vacuum insulation panel. Both ends of the box body 1 are provided with airtight doors 2, and the upper part of the airtight door 2 is hinged on the top of the box body 1 through door shafts. The two hydraulic cylinders 11 are all symmetrically arranged at both ends of the top of the box body 1, and the piston rods of each second hydraulic cylinder 11 are hinged on the corresponding sealing door 2, and the mating surfaces of each sealing door 2 and the box body 1 are uniform. A seal 3 is provided;

[0024] Both sides of the box body 1 are provided with a plurality of first hydraulic cylinders 4, and the plurality of first hydraulic cylinders 4 correspond to each other and their piston rods are arranged oppositely. On the piston rod of each of the first hydraulic cylinders 4 Both are fixedly provided with a pressure plate 5, a support plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com