New-energy cold and heat air exchange system of air conditioner for automobile

A new energy vehicle and air exchange technology, applied in air handling equipment, vehicle parts, heating/cooling equipment, etc., can solve the problems of energy efficiency ratio of only 1.3-1.6, insufficient processing accuracy, battery consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

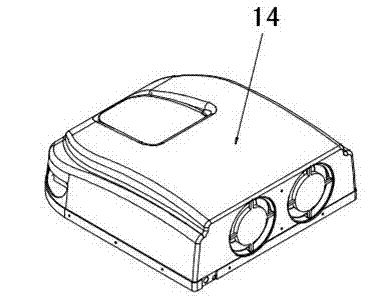

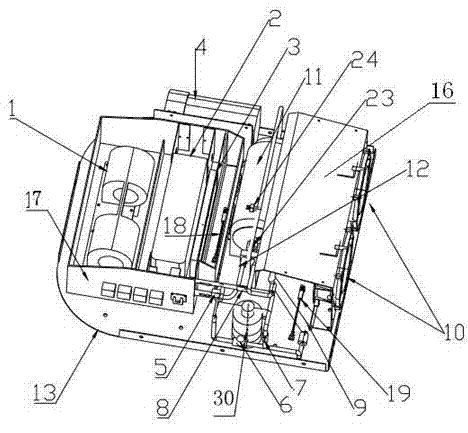

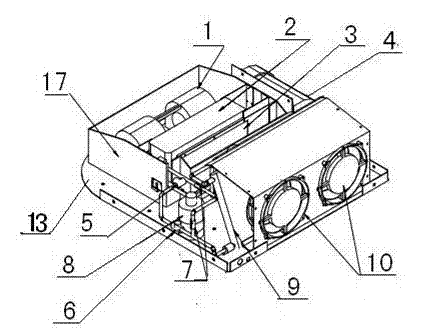

[0033] Taking the overhead electric air conditioning system as an example, the system is designed in a streamlined shape based on the principles of aerodynamics and aesthetics. The front end is an evaporator box, and the air inlet and outlet are connected to the top of the car at the bottom. The evaporator adopts a high heat transfer effect stacked structure (parallel flow structure can also be used), and the heat transfer power reaches 6kw. The evaporator fan adopts DC brushless centrifugal Fan, stepless speed regulation, power 120w, maximum air volume 500 cubic meters per hour. The rear end is a condenser, which adopts a double-layer parallel flow structure, and the heat exchange power reaches 8kw; the condensing fan is two 8-inch axial flow brushless fans that draw air backwards, each fan has a power of 100w, and the total air volume reaches 1800 cubic meters per hour. There are enough large and beautiful air inlets on the left and right front and middle parts of the casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com