Temperature control method and system of microwave oven, and microwave oven

A temperature control method and technology of a temperature control system, which are applied in the field of microwave heating furnace control and temperature control of microwave heating furnaces, can solve the problems of expensive implementation methods, complicated operation steps, etc. The effect of strong interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

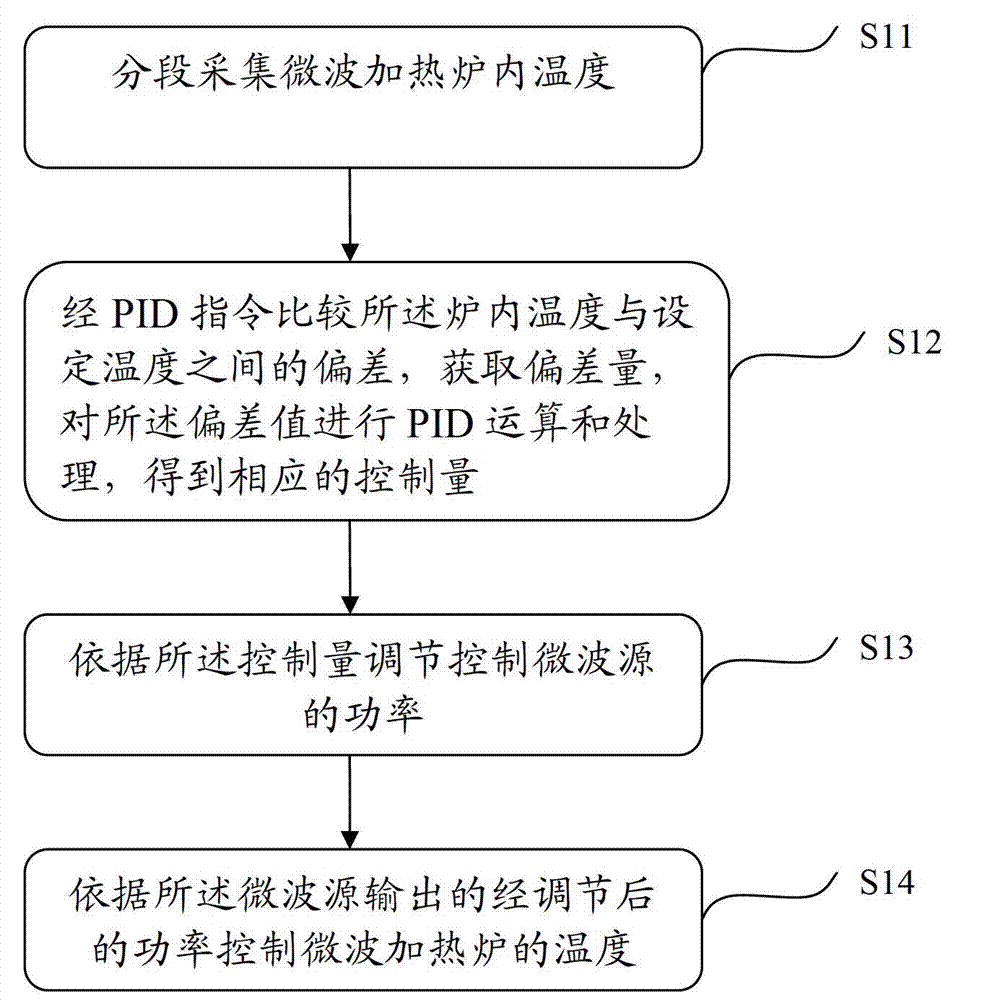

[0044] The flow chart of the temperature control method of the microwave oven disclosed in Embodiment 1 of the present invention is as follows: figure 1 shown, including:

[0045] Step S11: collecting the temperature in the microwave heating furnace in sections.

[0046] In the process of executing step S11, it is based on the thermocouples placed in each segment in the segmented space in the microwave heating furnace. Each thermocouple is used to collect the temperature in the furnace of the section where it is located. When the temperature of the section is required by the controller, the thermocouple corresponding to the section will collect the temperature of the corresponding section.

[0047] Step S12: Comparing the deviation between the temperature in the furnace and the set temperature through the PID command, obtaining the deviation amount, performing PID calculation and processing on the deviation value, and obtaining the corresponding control amount.

[0048] When...

Embodiment 2

[0068] The process flow of the temperature control method of the microwave oven disclosed in Embodiment 2 of the present invention is as follows: Figure 4 shown, including:

[0069] Step S41: collecting the temperature in the microwave heating furnace in sections;

[0070] Step S42: Comparing the deviation between the temperature in the furnace and the set temperature through the PID command, obtaining the deviation amount, performing PID calculation and processing on the deviation value, and obtaining the corresponding control amount;

[0071] Step S43: adjusting and controlling the power of the microwave source according to the control amount;

[0072] Step S44: Control the temperature of the microwave heating furnace according to the adjusted power output by the microwave source.

[0073] Step S45: When performing the temperature control method of the microwave heating furnace, display the data generated by each operation in real time, the data including: the temperature...

Embodiment 3

[0077] The process flow of the temperature control method of the microwave heating furnace disclosed in Embodiment 3 of the present invention is as follows: Figure 5 shown, including:

[0078] Step S51: collecting the temperature in the microwave heating furnace in sections;

[0079] Step S52: Comparing the deviation between the temperature in the furnace and the set temperature through the PID command, obtaining the deviation amount, performing PID calculation and processing on the deviation value, and obtaining the corresponding control amount;

[0080] Step S53: adjusting and controlling the power of the microwave source according to the control amount;

[0081] Step S54: Control the temperature of the microwave heating furnace according to the adjusted power output by the microwave source.

[0082] Step S55: When performing the temperature control method of the microwave heating furnace, display the data generated by each operation in real time, the data including: the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com