Vortex generating device

A eddy current generation and eddy current technology, which is used in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of easy fouling, blockage and poisoning of catalysts, and large investment costs of catalysts, so as to reduce construction investment and operating costs. , the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

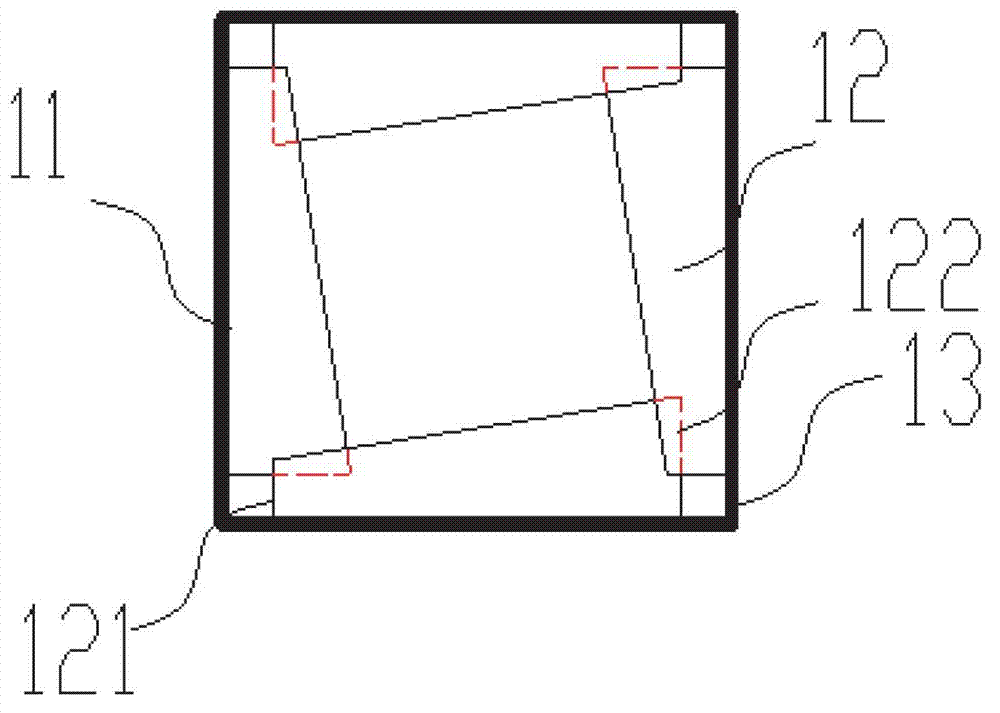

[0030] Figure 1~6 Provide a kind of vortex generator, it is characterized in that: comprise n (such as figure 1 Shown as 9×15) the vortex generating units 11 are arranged in a rectangular shape.

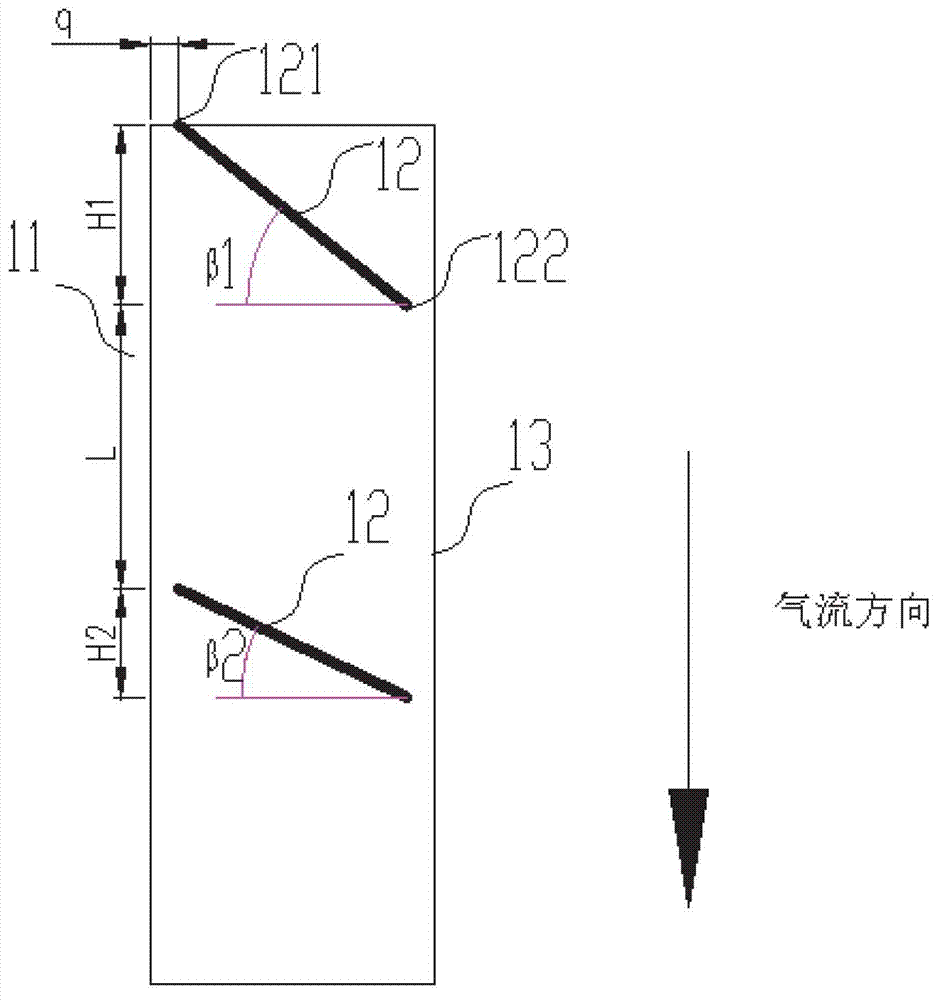

[0031] Each vortex generating unit 11 includes a square channel formed by four partitions 13 of the same size, that is, the cross section of the square channel is a square. The height (ie, depth) of the square channel is 200-500 mm, and the side length of the cross section of the square channel is 80-200 mm.

[0032] Two vortex guide vane assemblies are arranged along the airflow direction in the square channel, that is, the first vortex guide vane assembly (that is, close to the air inlet) and the second vortex guide vane assembly (that is, away from the air inlet, near the air outlet), The 2-stage vortex guide vane assemblies are spaced from each other.

[0033] The structure of each vortex guide vane assembly is as follows:

[0034] Each stage of the vortex guide vane assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com