Weathered collophanite graded processing technique

A processing technology and technology of collophosphate rock, which is applied in the field of quality separation processing of weathered collophosphate rock, can solve the problems of difficult density, low utilization rate of resources, inability to carry out long-term production, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

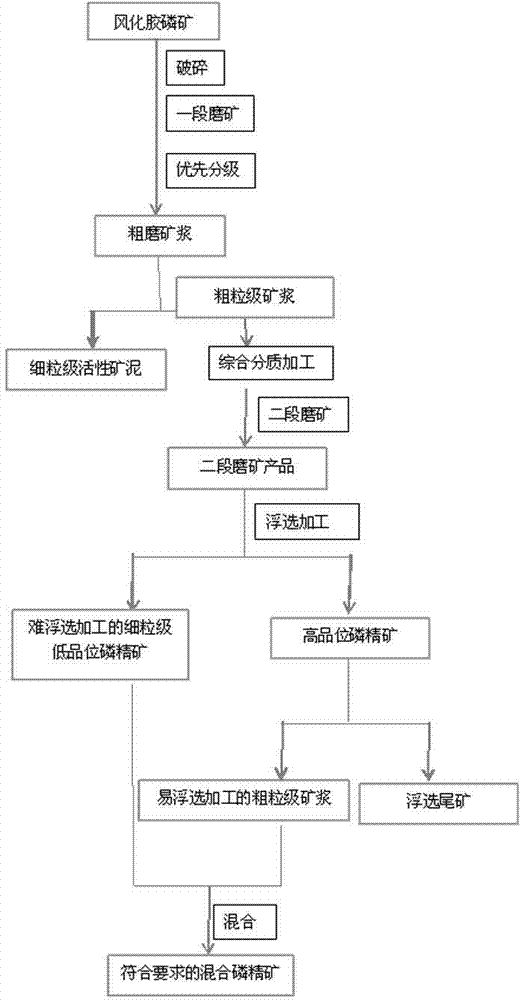

[0025] A sorting processing technology of weathered collophosphine, which is characterized in that the process flow is as follows: after the weathered collophosphate is crushed, a stage of grinding is carried out—the first stage of grinding products is preferentially graded—the fine-grained product is active slime—coarse The product of particle size is ore pulp entering the second-stage grinding—the product of the second-stage grinding is subjected to comprehensive quality separation processing—the product processed by easy flotation is relatively coarse-grained pulp entering the flotation processing system to produce high-grade phosphorus concentrate——difficult to float The selected and processed products are finer-grained pulp directly used as low-grade phosphorus concentrate, and the active slime obtained by prior classification can be directly sold as low-efficiency fertilizer. High-grade phosphorus concentrate is mixed with low-grade phosphorus concentrate to form the final...

Embodiment 2

[0041] The raw ore was crushed in the laboratory and ground to -0.074mm with a rod mill, accounting for 42.07%.

[0042] (1) The chemical composition of the comprehensive ore sample is:

[0043] Ore P 2 o 5 MgO Fe 2 o 3 al 2 o 3 SiO 2

[0044] Content 24.74 0.20 2.23 1.73 29.95

[0045] (2) Using hydrocyclone for priority classification, the yield of coarse-grained grade after removing fine-grained sludge is 80.54%, and the chemical composition is:

[0046] Ore P 2 o 5 MgO Fe 2 o 3 al 2 o 3 SiO 2

[0047] Content 25.35 0.16 1.29 1.34 30.42

[0048] (3) The coarse-grained part is ground to -0.074mm mesh by laboratory ball mill, accounting for 91.24%;

[0049] (4) Use a 165mm diameter hydrocyclone for grading

[0050] The purpose of using the hydrocyclone for grading is to classify the ground ore with 0.030mm as the cut-off point, and control the ore with a grade greater than 0.030mm in the sand settling products of the hydrocyclone to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com