Production method of steel-plastic composite pipe

A steel-plastic composite pipe and a production method technology, which is applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems that plastics are not longitudinally reinforced, steel reinforcements are corroded, and the longitudinal stability of pipes is low, and the longitudinal stability of pipes is eliminated. The effect of low tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

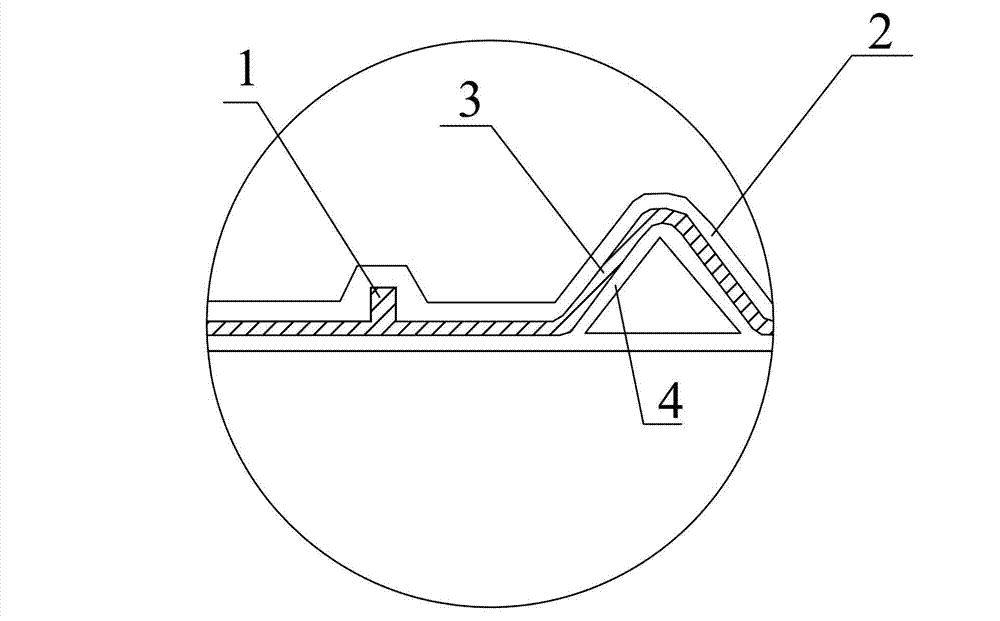

[0024] The production method of steel-plastic composite pipe is characterized in that by the following steps:

[0025] (1) Pass the steel belt with the designed width through the steel belt retracting device, under the traction of the steel belt traction device, successively pass through the steel belt derusting device for derusting, and then dry it through the air drying heating device, and then enter the inner plastic coating layer for extrusion The coating mold of the extruder makes the molten plastic extruded by the extruder cover the inner layer of the steel strip under pressure, and the edges of the two sides of the steel strip are not covered, which is used for arc welding in the subsequent process;

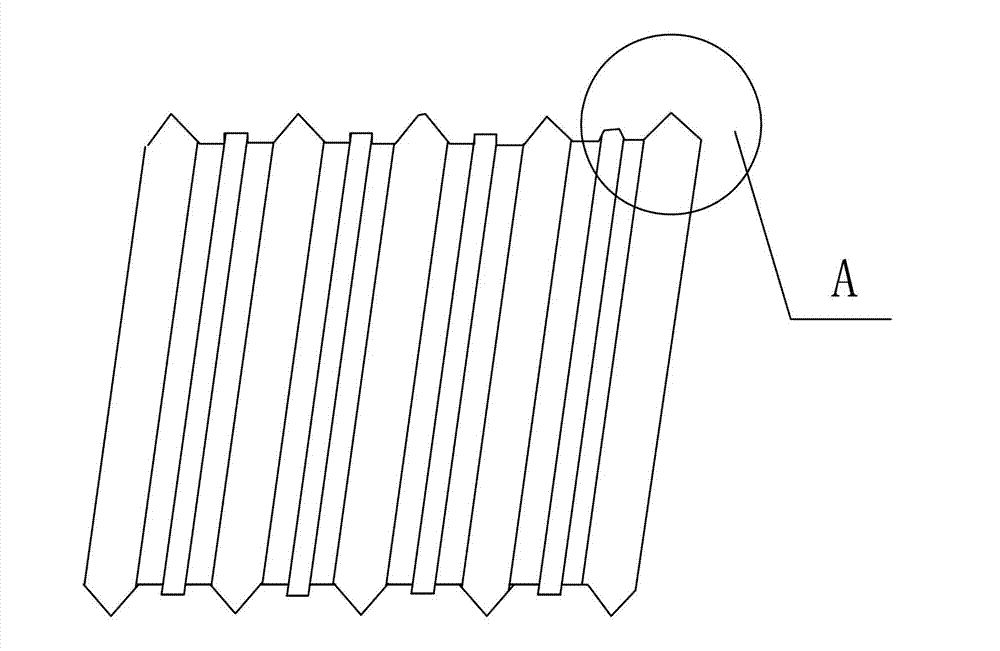

[0026] (2) The clad steel strip after cooling and shaping, under the traction of the cladding steel strip tractor, enters the strip shaping device, and presses out the waveform of the designed structural wall pipe on the strip to improve the ring shape of the pipe after for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com