Automatic material dumping lifter

A hoist, automatic technology, applied in emptying containers, bottle filling, packaging, etc., can solve the problems of wasting manpower and material resources, hidden dangers to operator safety, low degree of automation, etc., to reduce input costs, improve safety, and save manpower physical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

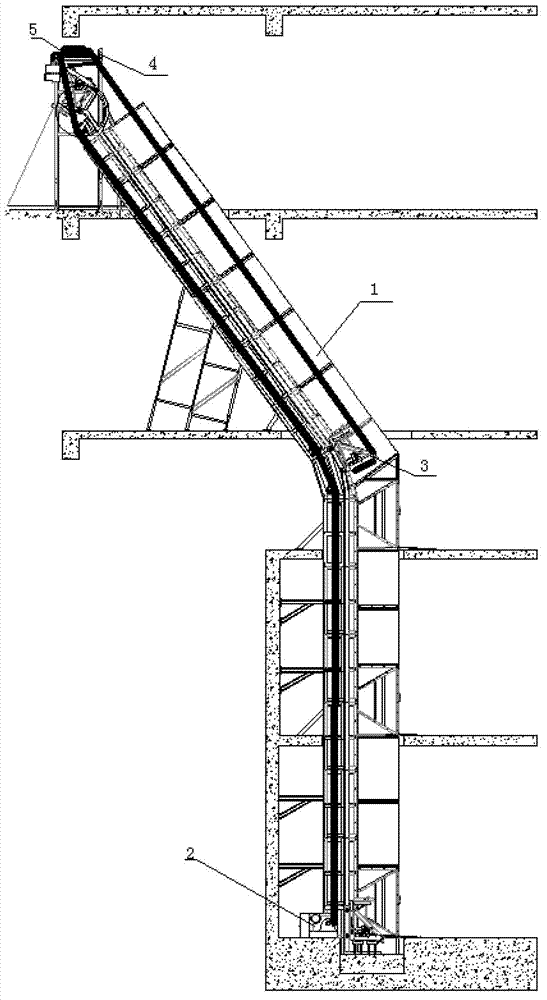

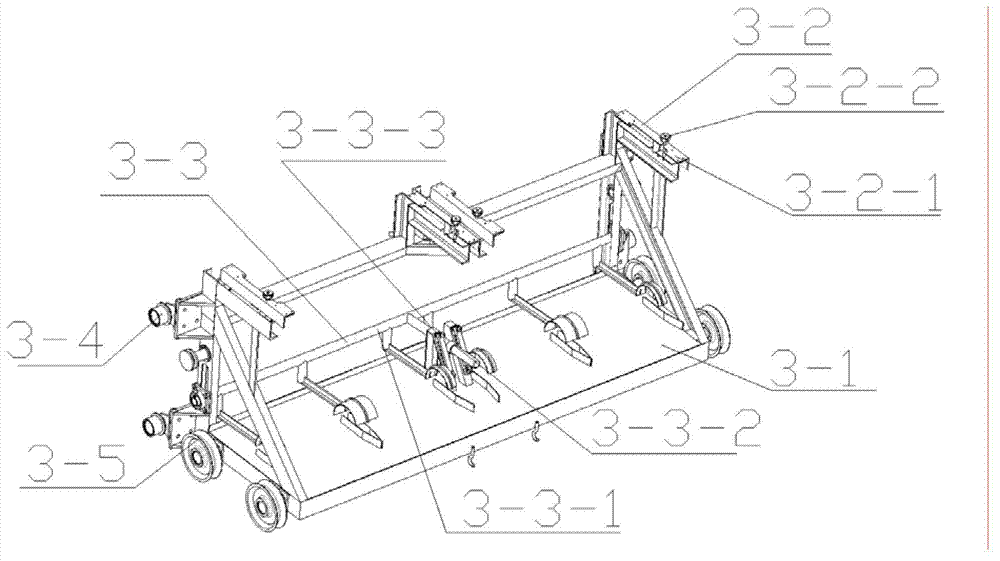

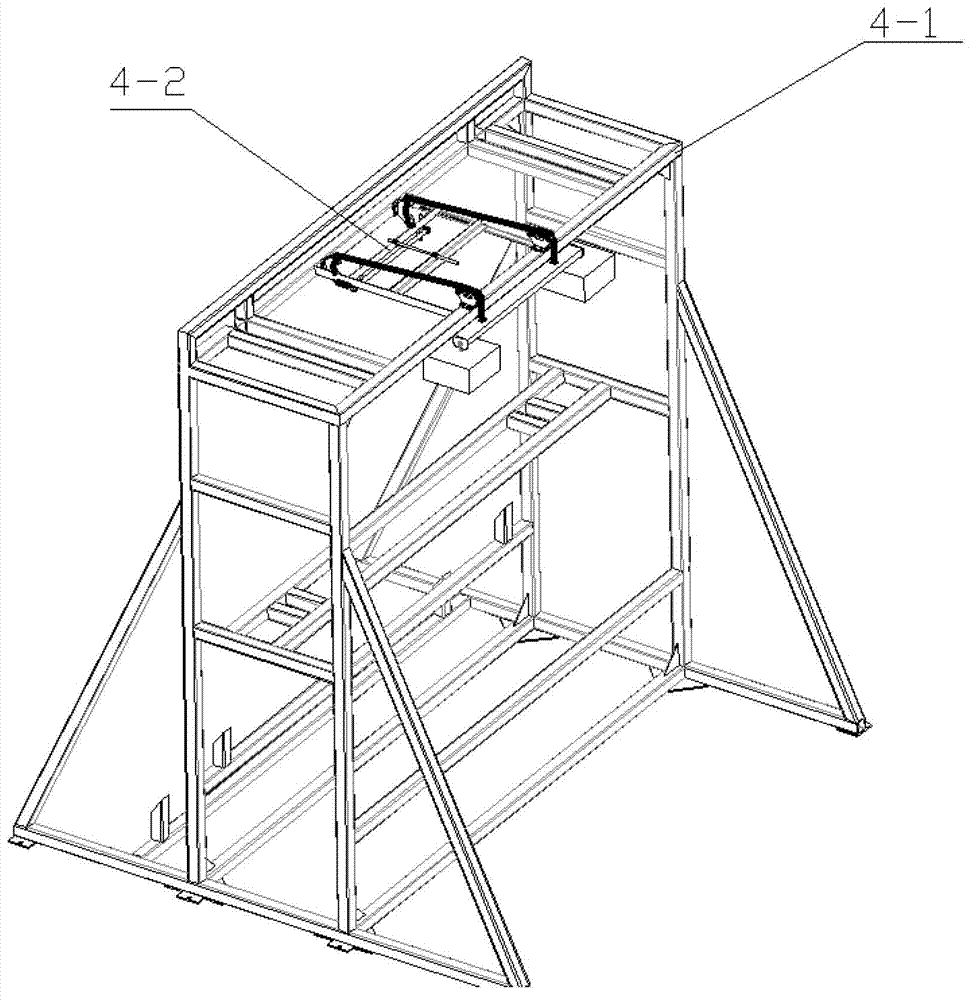

[0026] See Figure 1 ~ Figure 3 , an automatic dumping hoist for materials, which is composed of a main frame body 1, a winch 2, a feeding trolley 3, a turning mechanism 4 and a wire rope pulley mechanism 5, etc., wherein the main frame body 1 is composed of a standard section frame body and a non-standard section frame body Spliced together, the fuselage is all protected by PVC boards, which is safe and beautiful; the lifting material is not vertically lifted, but the main frame body 1 is redirected in the middle, and it is inclined 36° relative to the vertical direction, which can reduce The transportation link greatly reduces the input cost.

[0027] Hoist 2 is made up of components such as frame body, geared motor, brake, wire rope dru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com