Controlled-release zinc fertilizer and preparation method thereof

A zinc fertilizer and core fertilizer technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of easy loss of coating slow/controlled release, expensive organic zinc, and increased fertilizer costs, so as to meet crop absorption Requirements, long effective time, long nutrient release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

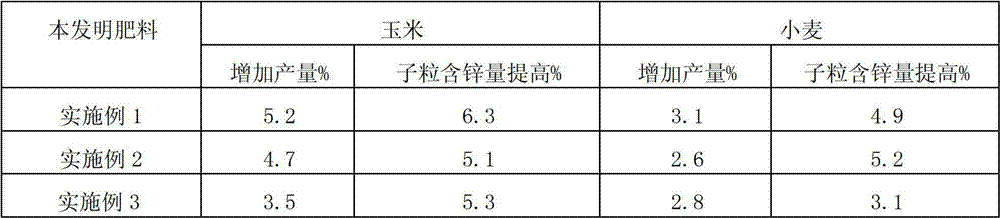

Examples

Embodiment 1

[0046] A controlled-release zinc fertilizer, the raw material composition of the core fertilizer is: 600 kg of zinc sulfate heptahydrate, 150 kg of weathered coal, 200 kg of urea, and 50 kg of bentonite. The inner sulfur coating accounts for 12wt% of the core fertilizer mass; the amount of the outer coating modified epoxy resin coating accounts for 2wt%, 3wt%, and 4wt% of the core fertilizer mass respectively. It is obtained by mixing at a mass ratio of 1:1:1.

[0047] Preparation method, the steps are as follows:

[0048] (1) According to the ratio, take 600 kg of zinc sulfate heptahydrate, 150 kg of weathered coal, 200 kg of urea, and 50 kg of bentonite, mix them evenly, and granulate them with a drum to prepare a granular fertilizer with a particle size of 2-3 mm to obtain the core Fat.

[0049] (2) Take 449 kg of epoxy resin E-4, 1 kg of polyurethane (PUR), mix well, add 1 kg of curing agent T-593, 1.5 kg of diluent benzyl glycidyl ether and 0.1 kg of corn starch, and mi...

Embodiment 2

[0056] A controlled-release zinc fertilizer, the raw material composition of the core fertilizer is: 500 kg of zinc sulfate heptahydrate, 200 kg of weathered coal, 240 kg of urea, and 60 kg of bentonite.

[0057] Preparation method, as described in Example 1, the difference is:

[0058] (1) Take 500 kg of zinc sulfate heptahydrate, 200 kg of weathered coal, 240 kg of urea, and 60 kg of bentonite, mix them evenly, and granulate them with a drum to prepare a granular fertilizer with a particle size of 2-3 mm to obtain core fertilizer.

[0059] (2) The modified epoxy resin coating agent is the same as in Example 1.

[0060] (3) Take 180 kg of core zinc fertilizer prepared in step (1), preheat to 80°C in the preheating container, transfer the fertilizer to the drum, and spray molten sulfur into the drum through the nozzle to continuously On the rotating fertilizer particles, a sulfur film is formed, and the mass of the sulfur film accounts for 15wt% of the core fertilizer mass, s...

Embodiment 3

[0064] A controlled-release zinc fertilizer raw material composition is: 700 kg of zinc sulfate heptahydrate, 100 kg of weathered coal, 130 kg of urea, and 70 kg of bentonite.

[0065] The preparation method is:

[0066] (1) According to the ratio, take 700 kg of zinc sulfate heptahydrate, 100 kg of weathered coal, 130 kg of urea, and 70 kg of bentonite, mix them evenly, and granulate them with a drum to prepare a granular fertilizer with a particle size of 2-3 mm to obtain core zinc Fat.

[0067] (2) The modified epoxy resin coating agent is the same as in Example 1.

[0068] (3) Take 240 kg of the core zinc fertilizer prepared in step (1), preheat it to 75°C in the preheating container, transfer the fertilizer to the drum, and spray molten sulfur into the drum through the nozzle to keep rotating On the fertilizer particles, a sulfur film is formed, and the mass of the sulfur film accounts for 10wt% of the core fertilizer mass, and the sulfur-zinc fertilizer is obtained.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com