Polyvinyl chloride mixture for wires and cables and preparation method thereof

A polyvinyl chloride, wire and cable technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of increased manufacturing costs and processing costs, and achieve the effects of low cost, strong anti-friction, and high resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

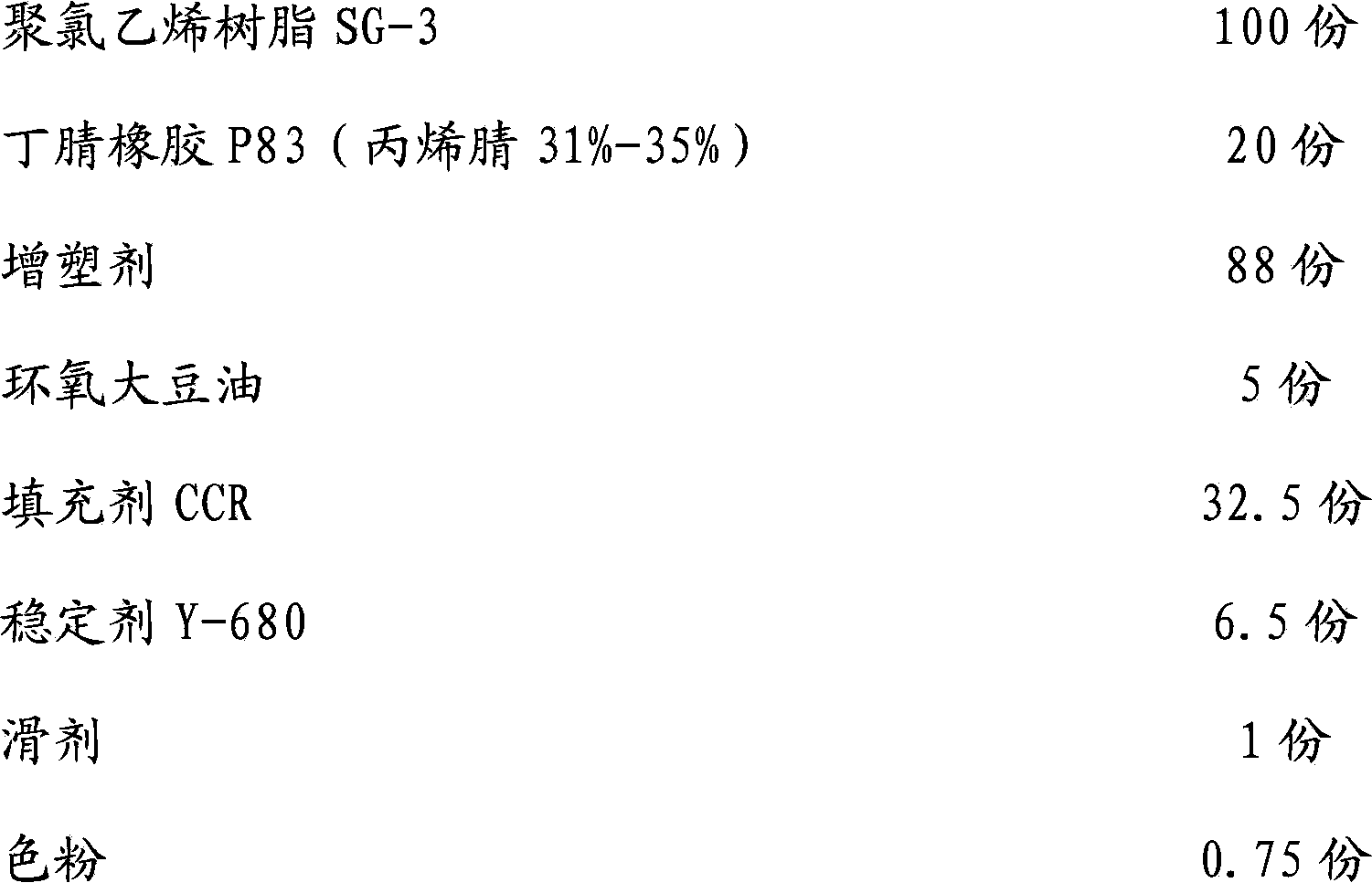

[0016] A polyvinyl chloride mixture for cold-resistant wire and cable, each component is prepared according to the following mass proportions:

[0017]

[0018] The mass fraction of DOP in the plasticizer described in Example 1 is 69 parts, and the mass fraction of DOA is 19 parts.

[0019] Add the polyvinyl chloride resin SG-3, plasticizer, stabilizer Y-680, filler CCR, epoxy soybean oil, slip agent, and toner in the high-speed mixer and stir, stir evenly and After reaching 90°C±3°C, add nitrile rubber P83 (acrylonitrile 31%-35%) into the high-speed mixer for secondary stirring, and the time of secondary stirring is controlled at 50-80 seconds to prevent premature formation of nitrile rubber After stirring evenly, put the mixture into the cold mixer for stirring, and at the same time send it to the pre-heated granulator, control the extrusion temperature of the granulator at 140°C±3°C, after extrusion, pelletizing To obtain the required polyvinyl chloride mixture for wire...

Embodiment 2

[0022] The mass share of DOP in the plasticizer described in embodiment two is 50 parts, and the mass share of DOA is 15 parts; in the plasticizer described in embodiment three, the mass share of DOP is 10 parts, and the mass share of DOA is 10 parts. The mass share is 6 parts. In other embodiments, DOA wherein also can be replaced by other cold-resistant plasticizers, DOP also can be by any one in DINP, DIDP and TOTM or any several in DOP, DINP, DIDP and TOTM combination instead.

[0023] The polyvinyl chloride mixture of Example 1 has the following electrical properties and mechanical properties after testing:

[0024] 1. Electrical properties

[0025] 1. Volume resistivity:

[0026] ≥10 at 20°C 13 Ω.cm ≥10 at 70°C 10 Ω.cm

[0027] ≥10 when the maximum conductor temperature is 70°C during normal operation 10 Ω.cm

[0028] 2. Insulation resistance constant:

[0029] ≥36.7MΩ.km at 20°C

[0030] 0.037MΩ.km at the highest conductor temperature of 70°C during normal ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com