Connection positioning device between valve shaft and valve plate of butterfly valve

A positioning device and valve shaft technology, applied in valve devices, lift valves, engine components, etc., can solve the problems of scrapped cone pins, low efficiency, and difficulty in mass production, saving materials, reducing costs, and high assembly efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

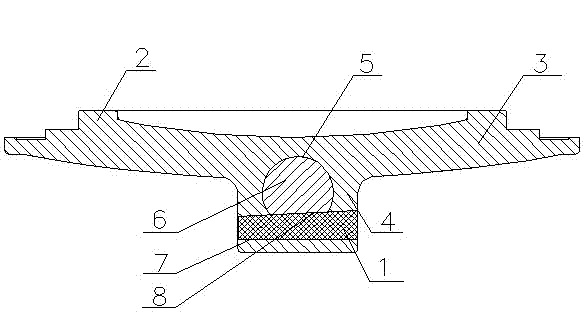

[0008] Such as figure 1 As shown, the valve plate 1 of the present invention includes a valve disc 3 and a valve shaft seat 4, the valve shaft seat 4 is provided with a vertical through hole 5 for passing through the valve shaft 6, and the valve shaft seat 4 is provided with a valve shaft seat for positioning connection The circular positioning hole 7 arranged laterally on the valve shaft 6 is provided with a wedge-shaped groove 8 at a position in contact with the circular positioning hole 7 on one side of the valve shaft 6, and a wedge-shaped pin 1 is inserted in the circular positioning hole 7. , the wedge-shaped pin 1 has the same diameter as the circular positioning hole 7, and the side contacting with the valve shaft 6 is a semi-cylindrical body with an inclined surface matched with the wedge-shaped groove 8 of the valve shaft 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com